Chapter 6-installation, Chapter 7-system start up/ troubleshooting – Magnum Venus Plastech PRESSURE LIMIT VALVE PLV-1000 User Manual

Page 24

MAINTAINENCE AND REPAIR MANUAL

PLV-1000

MAGNUM VENUS PLASTECH

REV 1.00

APRIL 2010

PAGE 24

CHAPTER 6-Installation

•

Before installing the PLV-1000, move the Poppet assembly up and down a few times by manually

pushing on the Poppet nut.

•

Making sure that a good thread sealer has been applied to the threads and replace the PLV-1000

back into the manifold or fitting that it was removed from.

•

Replace the Y or TEE fitting that was removed from the top.

•

Install the pneumatic lines back in the original position.

CHAPTER 7-System Start Up/ Troubleshooting

•

Turn up the operating pressure to approximately 10 psi.

•

Open recirculation valve and/or gun and remove any air from the system. While the air is purging

out check the PLV-1000 and make sure the Valve body is not venting the control signal.

•

Turn off recirculation valve and/or gun and turn up the operating pressure to correct operating

pressures.

•

Check for fluid leaks around PLV-1000

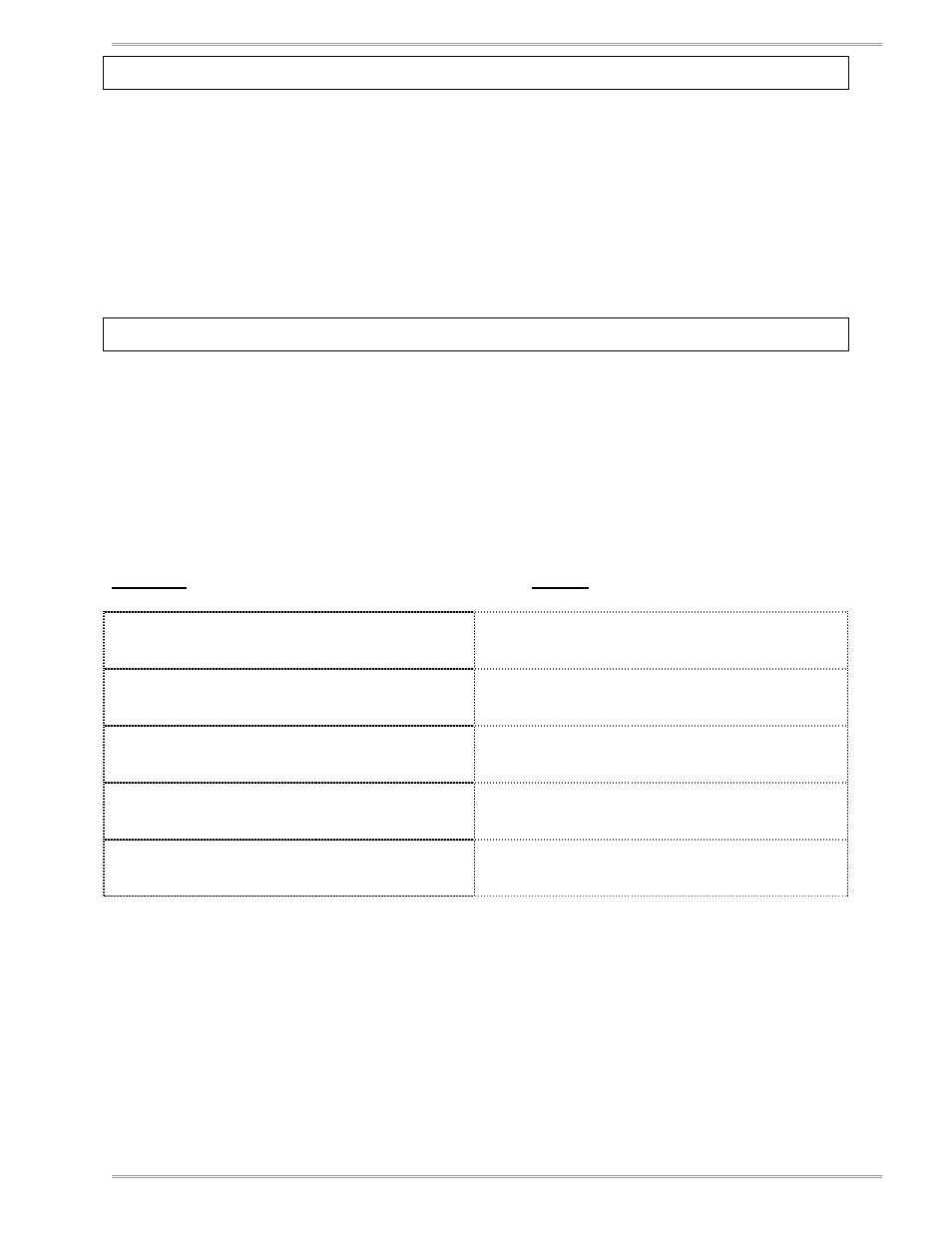

Problem

Cause

Control signal is not reaching control valve or

switch.

Check incoming signal to PLV-1000.

PLV-1000 is venting control signal.

Check O-ring on Poppet Stem.

Broken Spring.

PLV-1000 is venting at too low pressure.

Replace spring.

Check and replace O-ring on Poppet Stem.

PLV-1000 will not vent control signal.

Check for correct assembly.

Check that Poppet Stem moves freely and is not

bent.

Fluid is leaking from PLV-1000.

Replace Seal Assemblies and Needle Guide.