Magnum Venus Plastech ThermoJect V6SC User Manual

Page 15

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 15 of 17

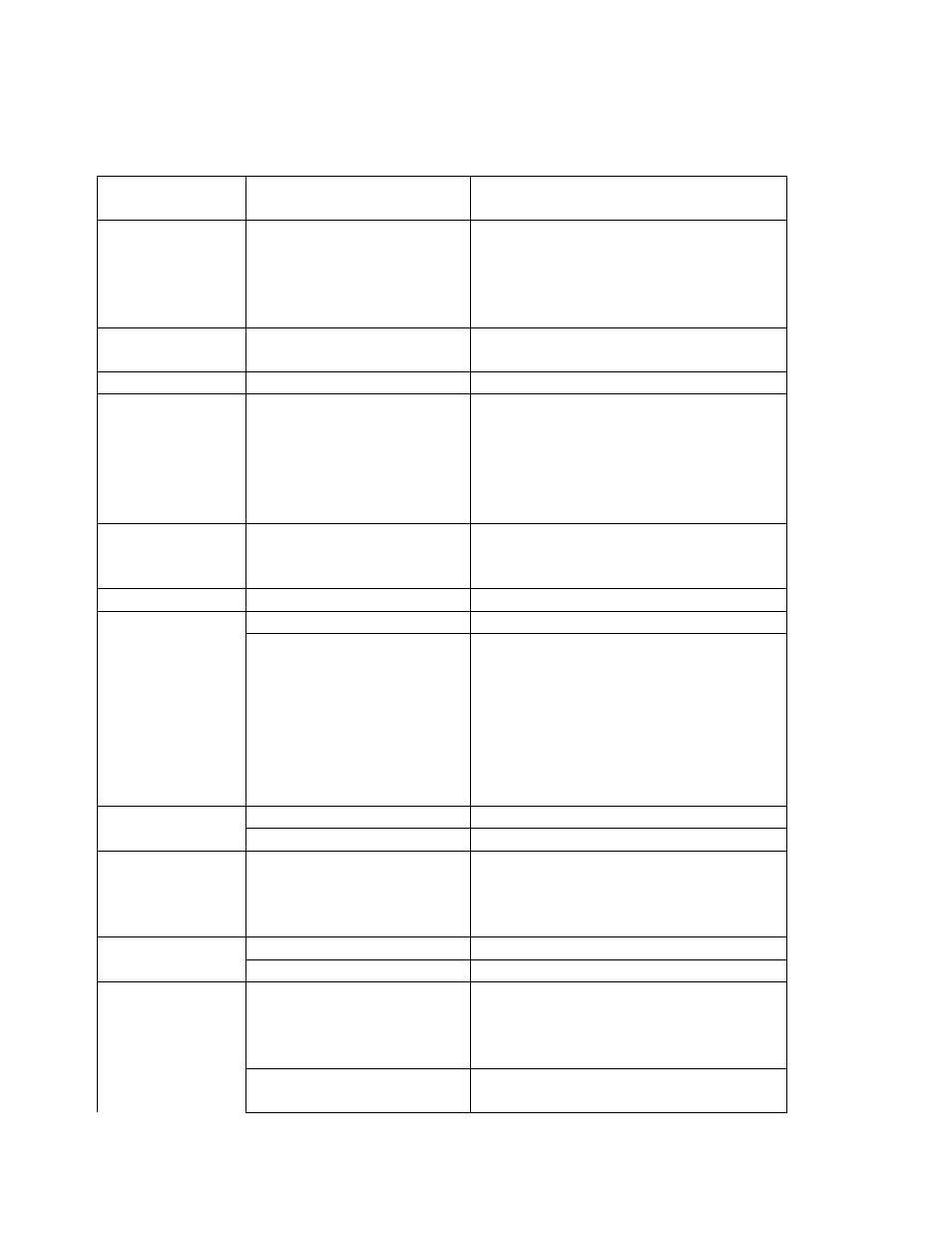

This table provides typical fault conditions their possible causes and remedies

Fault

symptom

Possible cause

Remedies

Machine fails to

start on

recirculation or

injection

command

1. Air supply too low

Ensure air supply at least 6 bar

(90psi)

2. Pump speed set too

low

Set at least to 1 bar and above

3. MPG set too low

Set MPG pressure higher

ON injection

command

( when green

button is

pressed)

Check Resin valve has moved to

open position. Observe Metal pin at

pneumatic actuator has moved out..

Approx 8 mm for Resin valve. If not

then increase shop air pressure or

service the valve at fault.

5. PDC Counter not

reset correctly or set at

zero

Press reset firmly or set at least a

count of 5

6. Resin head valve

blocked .This condition

could happen if the

machine has been left

with resin in the system

for extended times

without use.

Internally clean and if necessary

renew internal parts.

Caution NOTE. Always replace the

resin valve locking M5 screws

securely after servicing the Resin

auto valve.

Resin flow has

bubbles or

appears erratic

1. Air leaks in the resin

feed intake system.

1.Check all joints for leaks in intake

pipe work and fittings on the resin

pickup fluid section

Flush does not

clean efficiently

or appears

weak

1.Low air supply

pressure

Ensure supply pressure between 6

to 8 bar (90

– 120 psi)

2.solvent valve assy

blocked or broken

Check assy 58742-PLAS internal

seat and spring