Magnum Venus Plastech UltraMAX VLS-4600 Series User Manual

Page 38

VLS-4600 Series Fluid Section Manual

Rev. 08/2013

Page | 38

3

2.5

.5

1

1.5

2

2.3

1.0

.5

1.5

2.0

3.5

3

2

1.5

2.5

1

5

4

4.5

5.5

Fluid Section Information:

VLS-4600 Fluid Section is a part of a modular system that can fit a multiple of applications and a

multiple of configurations by changing a minimum of components. The VLS-4600 is designed to

deliver power, versatility and rugged construction for long lasting use. This fluid section features

Rapid Access Design (RAD) for easy access and maintenance.

Output Capabilities: Up to 8

– 10 lbs / min. (3.63 – 4.54 kg / min.), using GP resin of average

viscosity. As a general rule in the standard 11:1 configuration it will pump a GP resin of 1200cps to

1500cps maximum.

Air Consumption: In a chopper application with 2 strands of glass 18cfm (.5 m

3

/ min).

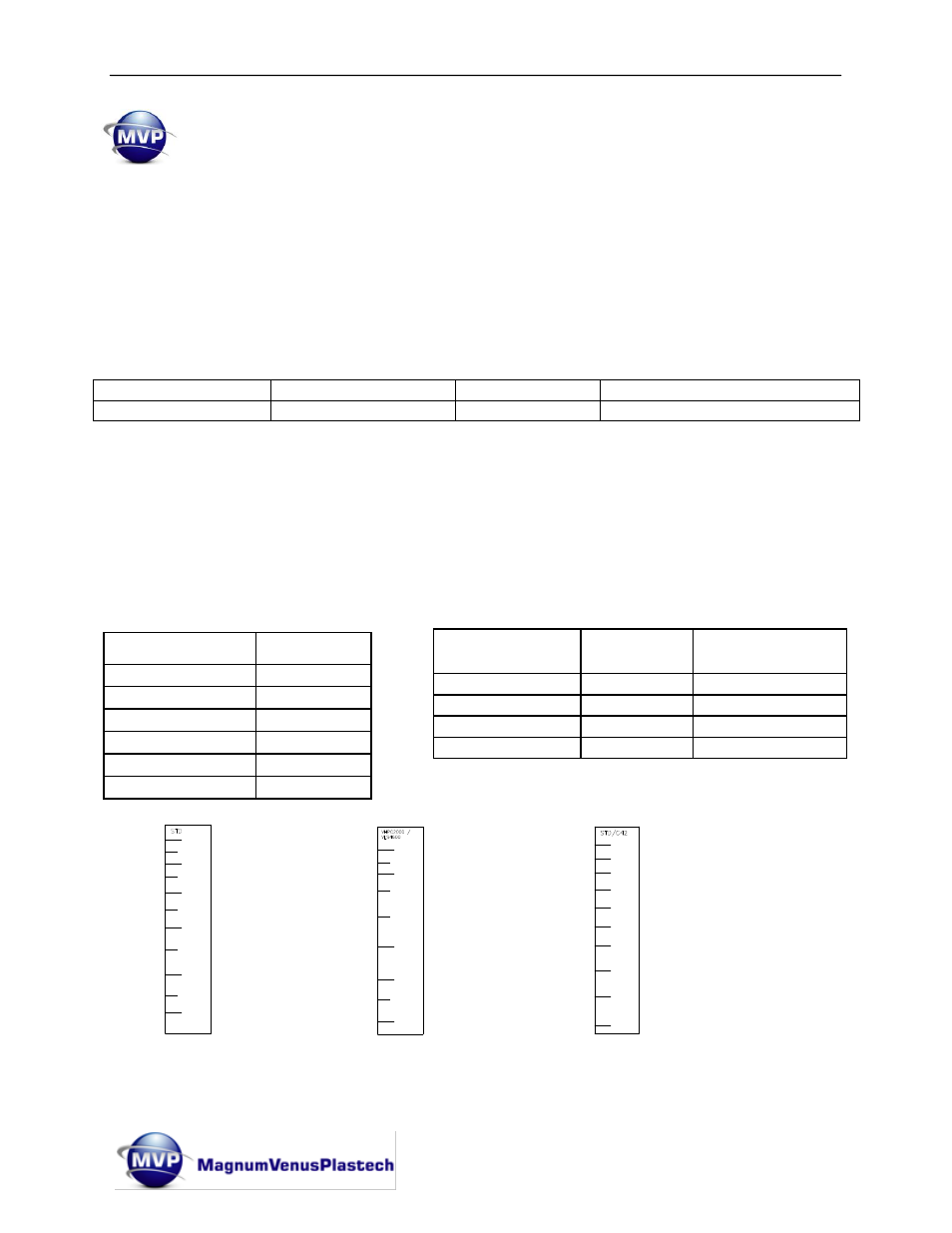

Catalyst Pump Percentage Chart

Power Head to Fluid Pump Ratio

Fluid Section

Pump Area (Sq. in)

Stroke Length

Displacement (in

3

) / Stroke

VLS-4600

1.143 (7.37 sq. cm)

4” (101.6 mm)

4.5 (73.74 cc) (.074 liter)

Power Head

VLS-4600

Air

Consumption

Diameter (in.)

VPH-3250

6 to 1

VPH-4250

11 to 1

9cfm (.25 m

3

/ min.)

VPH-5000

15 to 1

VPH-7000-HD

30 to 1

Catalyst Pump

VLS-4600

VHPC-2000

.5% - 2.3%

VHPC-1000

.5% - 3%

VHPC-4200

1% - 5.5%

VHPC-3200

2% - 12.5%

VHPC-2200

5%

– 20% +-

VHPC-1200

7%

– 25% +-

Filler loading: As a general rule using a GP resin and ATH or Calcium Carbonate in an 11:1

pump configuration you can fill up to 20% - 25%, in a 15:1 pump configuration up to 30% - 35%.

Higher percentages can be achieved by using low viscosity resins specially designed for fillers. It

is always a good idea to use resins that are designed for fillers as they will help keep the fillers in

suspension. Using fillers will increase pump wear and maintenance.

UPS-3101

VHPC-1000 Catalyst Pump &

VLS-4600 Fluid Section

UPS-3123

VHPC-2000 Catalyst Pump &

VLS-4600 Fluid Section

UPS-3122

VHPC-4200 Catalyst Pump &

VLS-4600 Fluid Section