Magnum Venus Plastech UltraMAX VLS-4600 Series User Manual

Page 36

VLS-4600 Series Fluid Section Manual

Rev. 08/2013

Page | 36

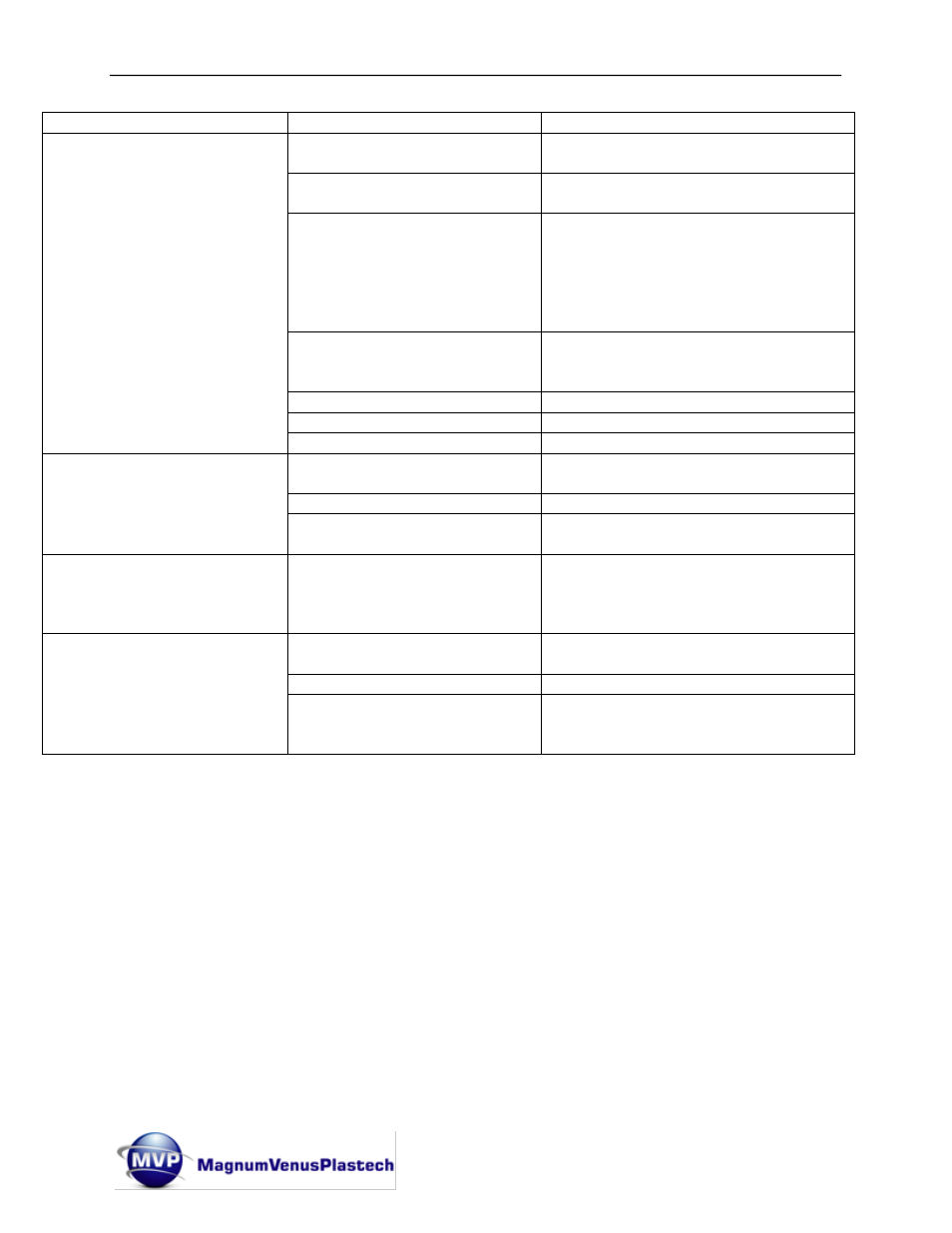

PROBLEM

CAUSE

SOLUTION

Pump does not run

Packing nut too tight

Loosen the packing nut and tighten

just a little more then hand tight.

Air Motor is stuck

Push the Reset button the bottom of

the air motor valve.

Fluid section or hose plugged.

Danger: To prevent injury,

always relieve fluid pressure

before attempting to remove

components.

Disassemble and clean Fluid section.

Replace any worn parts. Replace hose

as required.

Air not connected.

Check that air hose is connected at

manifold, and regulator is at 20 psi or

more.

Air restricted.

Straighten any kinks in air hoses.

Gun blocked or Seal rotated

Repair gun block or replace

resin system.

Gun is not opening

Check and repair gun triggering

Material in oil reservoir

Packing worn.

Replace packing set in lower part of

the pump.

Piston rod worn or scored.

Replace piston rod.

Packing Nut too loose

Tighten the Packing Nut a little more

then hand tight.

No Gel coat or Resin

delivery on down stroke

Foot valve, spring retainer, or

foot valve ball damaged or

dirty.

Clean or replace foot valve, spring

retainer, and foot valve ball. Be sure to

lubricate ball thoroughly with Red

Grease.

Hose leaks at fittings

Fitting loose

Tighten fitting. Check all fittings for

leaks before operating.

Fitting or nipple damaged.

Replace damaged parts.

Crimped hose

If the hose has been sharply bent, the

plastic liner may be ruptured. Remove

and replace hose.