Installation overview, Mechanical installation, Warning be prepared – Liquid Controls Differential Pressure Transducer User Manual

Page 6

6

Installation Overview

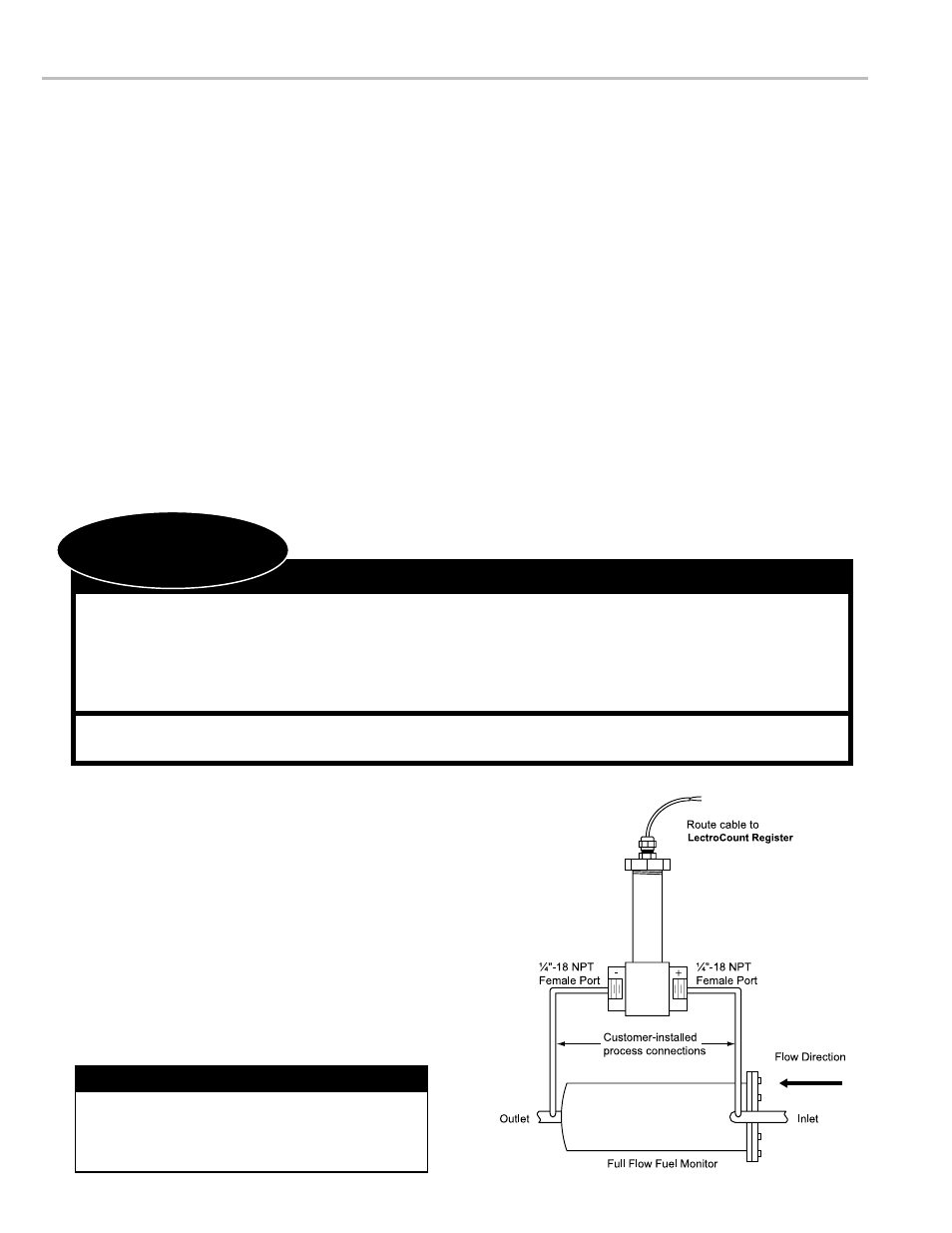

1. Install ΔP transducer and piping between a point immediately upstream and a point immediately downstream of the full flow

fuel monitor or water coalescer.

2. Wire the ΔP transducer to the LectroCount electronic register.

3. Set the shutdown value on the LectroCount LCR-II or LCR 600.

Mechanical Installation

Installation notes

•

The differential pressure transducer has two ¼"-18 NPT female ports. The transducer is shipped with a protective cap on each port.

These protective caps should remain in place until the transducer is ready to be connected to the process lines.

•

The transducer ports are marked with a “+” sign and a “-” sign. This designates the high pressure side and low pressure side,

respectively. Ensure that the transducer is installed in the correct orientation.

•

Ensure that the transducer is installed in a location where it will not be damaged.

•

The transducer is provided with a sixteen foot cable. If longer cable length is required, be sure to use compatible wire not smaller

than 24 gage.

•

Install the transducer with service in mind. Provide ample space for periodic inspection and maintenance.

Never attempt to clean out the transducer ports using

metal objects. Metal diaphragms located in these

ports may become scratched, punctured, deformed, or

damaged as a result.

Handle the transducer Ports with Care

Before disassembly of any meter or accessory component:

• All internal pressures must be relieved and all liquid drained from the system in accordance with

all applicable procedures.

• Pressure must be 0 (zero) psi.

• Close all liquid and vapor lines between the meter and liquid source.

Failure to follow this warning could result in property damage, personal injury, or death from

fire and/or explosion, or other hazards that may be associated with this type of equipment.

!

WarnInG

be Prepared

Safely Evacuate

Piping System

MechanIcal InstallatIon

to install the ∆P transducer:

1. Safely evacuate the piping system.

2. Determine the best location for the differential pressure

transducer and for the customer-installed process

connections to the full flow fuel monitor, water coalescer,

or other device to be monitored.

3. Connect each of the process tubes to the full flow fuel

monitor (or other device to be monitored). The process

tubing must be in compliance with the requirements

of the application. It is recommended that the process

tubing inner diameter should be at least 1/8" and have a

minimum rating of 150 PSI.