Opening to the outside” installation, Closed position open position, Support bar – Controlled Products Systems Group 6003-080 User Manual

Page 13: Rear bracket fabrication, Bottom middle top, Attaching brackets to surfaces

6003-065-Q-2-12

11

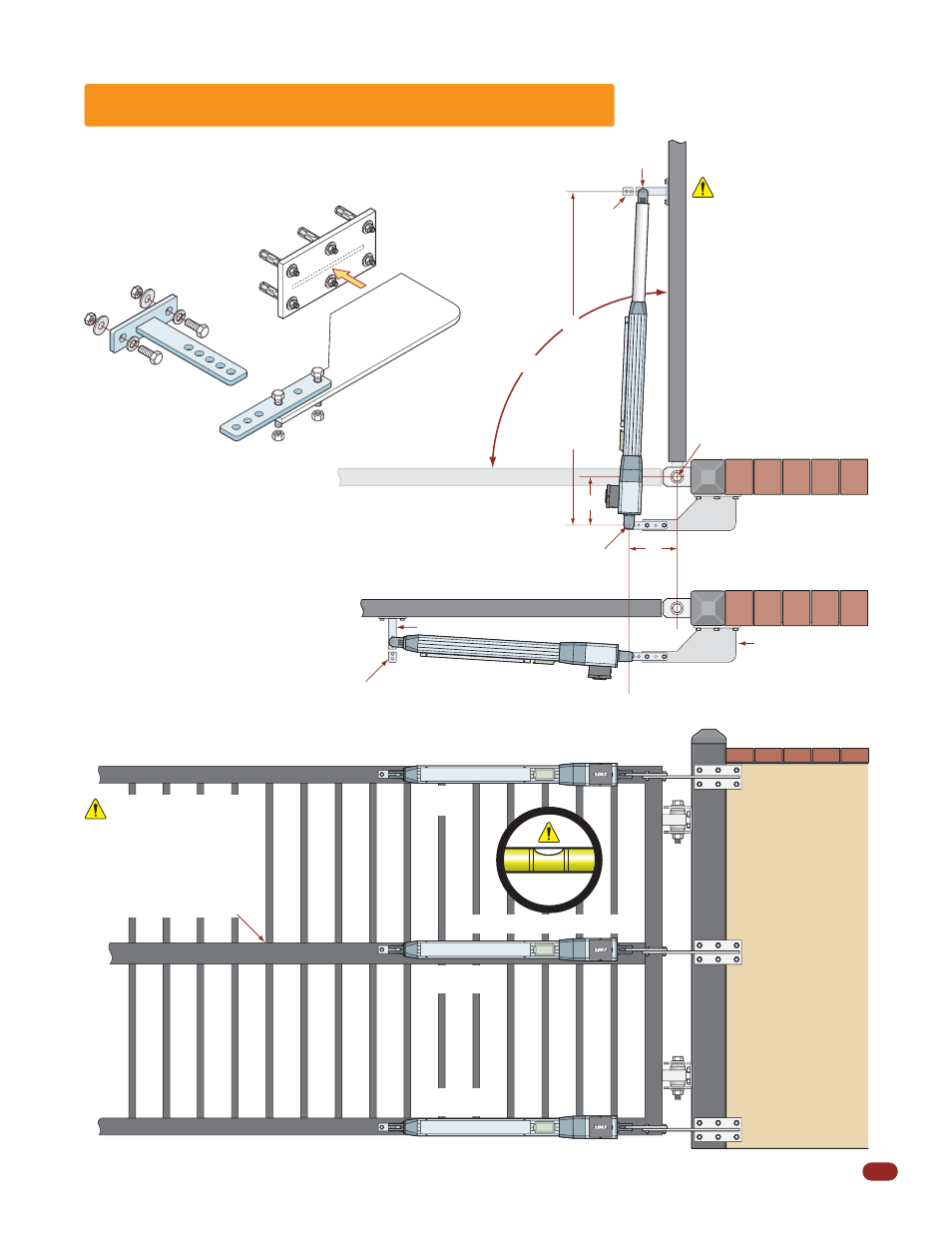

“Opening to the Outside” Installation

7”

Addition to

support bracket

must be

fabricated to

reach wall.

Gate Hinge Pivot Point

Front Bracket

Pivot Point

Gate in Closed Position

Rear Bracket Pivot Point

Closed Position

Open Position

Actuator arm MUST be level!

A support bar must span

the entire length of the

gate to support the gate

pickets. The pickets will

bend if not supported.

Support Bar

90°

7”

Rear Bracket

Do not install the

actuator in fully

extended (Bottomed out)

position. This will

damage the arm. See

next page to prevent this

from happening.

Hardware

(Not Supplied)

Front Bracket

Bolt or weld to gate.

Bolt rear support bracket

to fabricated steel plate

with supplied lock nuts.

Rear Support

Bracket

(Supplied)

Fabricated

Steel Plate

(Not Supplied)

Front Bracket

Cut Off

Excess

Bracket

Cut Off

Excess

Bracket

A rear bracket will need to be fabricated.

The bracket will vary in size depending on

the gate hinge inset. It can be attached to

the wall by welding or bolting, depending

on the type support post/wall.

The bracket MUST be level and VERY

secure to the wall.

Extreme force will

be exerted on this bracket during gate

cycling.

Rear Bracket Fabrication

Bottom Installation

Note: Make sure

that the operator is

mounted high

enough off the

ground that it will

NOT come in

contact with

standing or flowing

water. This will

damage the

operator.

Bottom

Middle

Top

Weld directly to support post

OR reinforcing steel plate

Support Post

Reinforcing steel plate

for sleeve anchors

if desired.

(Not Supplied)

47.5” Open Position

Note: The brackets must be perpendicular (Plumb) to

the gate and wall/post and horizontally level. If welding

brackets to surfaces, weld completely around brackets.

Attaching Brackets to Surfaces

Bolt or weld brackets to gate and support post/wall.