Controlled Products Systems Group 109773 User Manual

Page 4

20

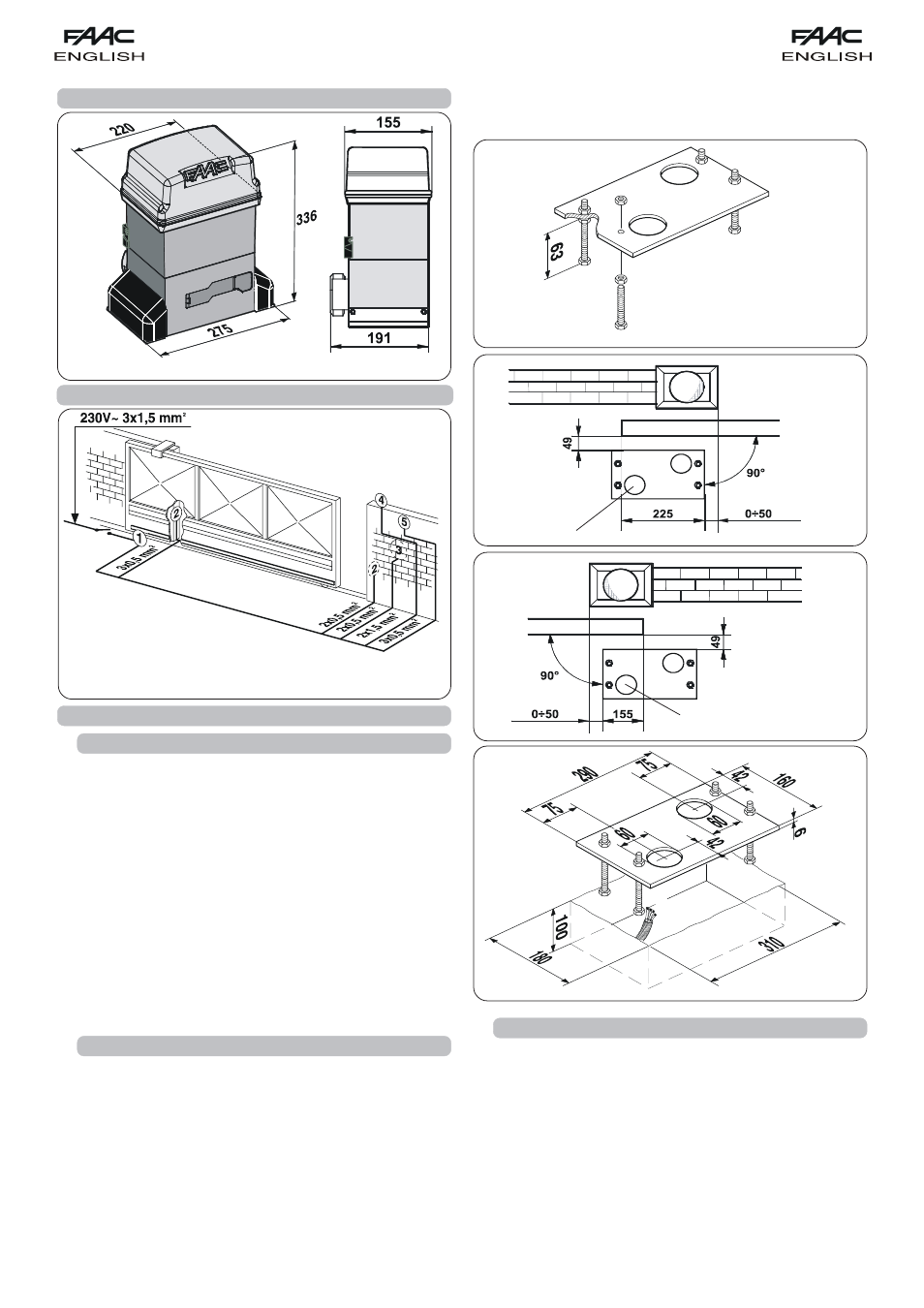

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 2

Fig. 3

2. DIMENSIONS

3. ELECTRIC EQUIPMENT (standard system)

To make the connections efficiently, allow the cables to

project by about 40 cm from the hole (Figs.5-6 ref.

³) of the

foundation plate.

4. INSTALLATION OF THE AUTOMATED SYSTEM

4.1.

PRELIMINARY CHECKS

To ensure safety and an efficiently operating automated system,

make sure the following conditions are observed:

•

The gate structure must be suitable for automation. The following

are necessary in particular: wheel diameter must be in proportion

to the weight of the gate to be automated, an upper guide must

be provided, plus mechanical stop limits to prevent the gate

derailing.

•

The soil must permit sufficient stability for the foundation plinth.

•

There must be no pipes or electric cables in the plinth excavation

area.

•

If the gearmotor is exposed to passing vehicles, install, if possible,

adequate means of protection against accidental impact.

•

Check if an efficient earthing is available for connection to the

gearmotor.

4.2.

MASONRY FOR FOUNDATION PLATE

1) Assemble the foundation plate as shown in figure 4.

2) The foundation plate must be located as shown in figure 5 (right

closing) or figure 6 (left closing) to ensure the rack and pinion

mesh correctly.

3) Prepare a foundation plinth as shown in fig.7 and wall the

foundation plate, supplying one or more sheaths for routing

electric cables. Using a spirit level, check if the plate is perfectly

level. Wait for the cement to set.

4) Lay the electric cables for connection to the accessories and

power supply as shown in figure 3.

4.3.

MECHANICAL INSTALLATION

1) Assemble the securing corners and anti-vibration spacers on

the operator as shown in Fig. 8.

2) Open the cover, unscrewing the securing screws.

3) Place the operator on the plate, using the supplied washers and

nuts as shown in Fig. 9.

During this operation, route the cables through the duct inside

the lower half-casing of the operator (Fig.10 - Ref. A).

To access the electronic equipment, route the cables through

the appropriate hole, using the supplied rubber cable-clamp.

Make absolutely sure to unsheathe all the cables so that the

clamp holds single cables only (Fig.10 - Ref. B).

³

³

ቢ

Operator 746

with 780D equipment

ባ

Photocells

ቤ

Key-operated push-button

ብ

Flashing lamp

ቦ

Radio receiver