Controlled Products Systems Group 109773 User Manual

Page 3

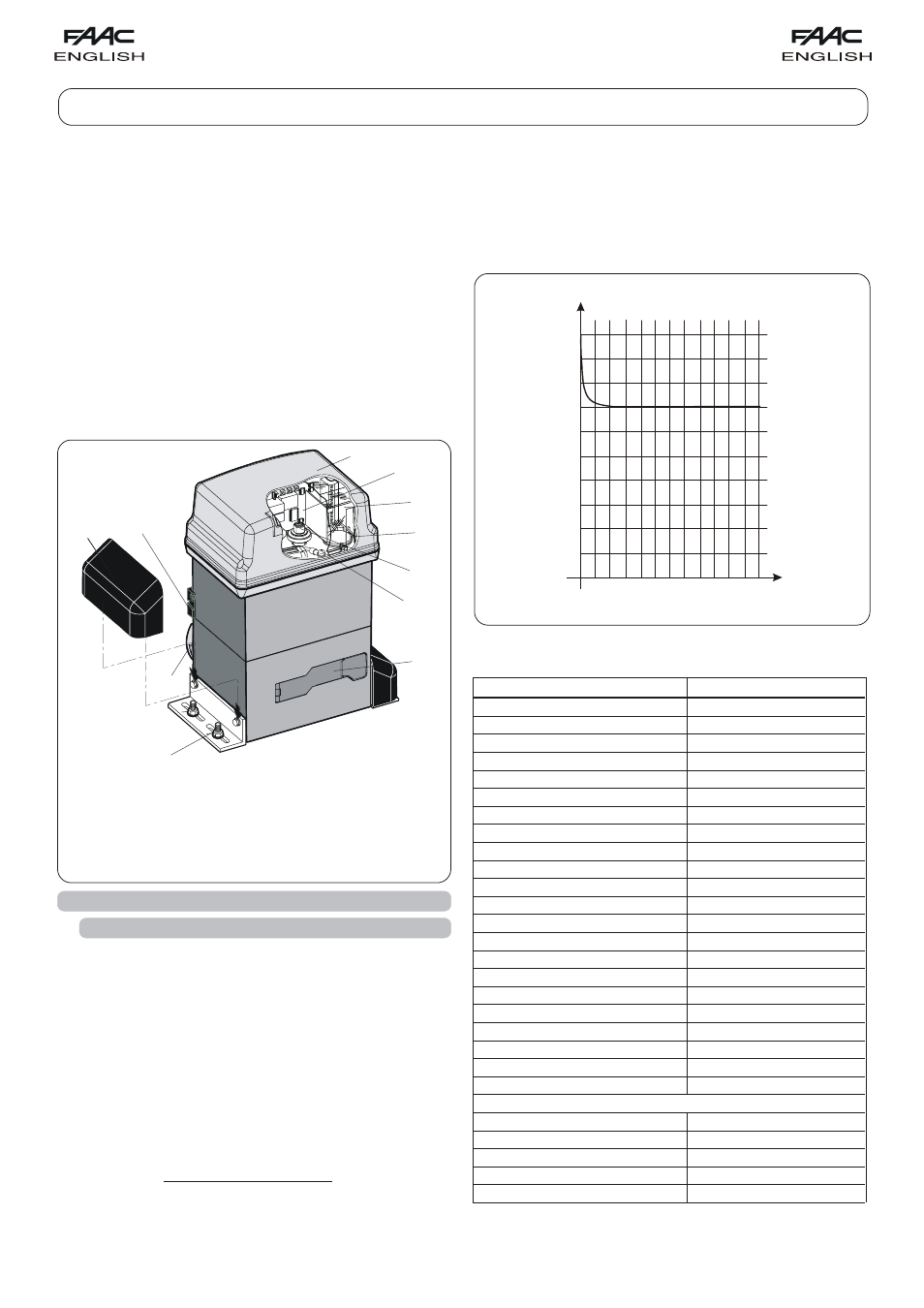

19

MODEL

746

Power supply (Vac +6% -10% 50-60Hz)

230

Absorbed power (W)

300

Reduction ratio

1 : 30

Type of pinion

Z20 - Z16

Rack

Module 4 - step 12.566

Max. thrust (daN)

50 (Z20) - 62,5 (Z16)

Max. Torque (Nm)

20

Winding thermal protection (°C)

120

Use frequency

70% (see graph)

Oil quantity (l)

1,8

Type of oil

FAAC XD 220

Operatine ambient temperature (°C)

-20 ÷ +55

Gearmotor weight (Kg)

14

Protection class

IP 44

Gate max. weight (Kg)

400 (Z20) - 600 (Z16)

Gate speed (m/min)

12 (Z20) - 9,6 (Z16)

Gate max. length (m) (time-out)

50 (Z20) - 40 (Z16)

Clutch

twin-disk in oil bath

Protective treatment

cataphoresis

Equipment

780D

Limit-switch

MSL or inductive

Gearmotor overall dimensions LxHxD (mm)

see Fig. 2

Electric motor technical specifications

RPM

1400

Power (W)

300

Absorbed current (A)

1.5

Starting capacitor (µF)

25

Power supply (Vac +6% -10%; 50-60Hz)

230

% Freq.

Utilizzo

% Fréq.

d’utilisation

% Benutzungs-

frequenz

% Frecuencia

de utilización

% gebruiks-

frequentie

% Duty

Cycle

0

10

20

30

40

50

60

70

80

90

100

1

2

3

4

5

6

7

8

9

10 11 12

Tempo (h)

Time (h)

Temps (h)

Zeit (h)

Tiempo (h)

werktijd (h)

These instructions apply to the following models:

746 ER Z16 - 746 ER Z20 - 746 ER CAT - 746 ER RF

The FAAC mod. 746 automated system for sliding gates is an

electro-mechanical operator transmitting motion to the sliding leaf

via a rack or chain pinion appropriately coupled to the gate.

The non-reversing system ensures the gate is mechanically locked

when the motor is not operating and, therefore, no lock needs to be

installed.

The gearmotor is equipped with a mechanical clutch which,

combined with an electronic device, offers the necessary adjustable

anti-crushing safety and guarantees stopping or reversing the gate

movement. A handy manual release makes it possible to move the

gate in the event of a power cut or malfunction. The electronic

control equipment is equipped with a gearmotor and is housed

inside the operator.

The 746 automated system was designed and manufactured to

control access of vehicles. Avoid any other use whatever.

Tab. 1

TECHNICAL SPECIFICATIONS OF 746 GEARMOTOR

where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti

= time of interval between two complete cycles

Use frequency graph

ቢ Securing corners

ባ Pinion

ቤ Limit sensor switch

ብ Operator cover

ቦ 780 D Control board

ቧ Adjustment screw for

anti-crushing clutch

ቨ Oil filling plug

ቩ Operator earthing

ቪ Lever operated release system

ቫ Protective side panels

ቭ Cover for 780D control board

AUTOMATED SYSTEM 746 & ELECTRONIC CONTROL UNIT 780D

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

1.1.

MAXIMUM USE CURVE

The curve makes it possible to establish maximum work time (T)

according to use frequency (F).

E.g.: The 746 gearmotor can operate non-stop at 70% use

frequency.

To ensure efficient operation, operate in the work range below the

curve.

Important: The curve is obtained at a temperature of 24°C. Exposure

to the direct sun rays can reduce use frequency down to 20%.

Calculation of use frequency

The percentage of effective work time (opening + closing) compared

to total time of cycle (opening + closing + pause times).

Calculation formula:

Ta + Tc

%F =

X 100

Ta + Tc + Tp + Ti

Fig. 1

ቧ

ባ

ቨ

ቦ

ብ

ቤ

ቭ

ቩ

ቪ

ቢ

ቫ