Controlled Products Systems Group 10441811 User Manual

Page 8

Guidelines for Determining Installation Dimensions

• For

90° leaf openings: A+B=L

• For leaf openings

exceeding 90°: A+B

• Smaller A and B dimensions provide higher periph-

eral leaf speed.

• Limit the difference between A and B dimensions to

less than 1.5 inches. Greater differences may cause

speed variations during gate opening and closing

movements.

• Maintain a Z dimension that ensures that the operator

does not strike the pillar.

• In LS models, limit switches are triggered during the

first and last

1.25 inches of gate travel. Therefore

select

A and B dimensions that utilize the entire opera-

tor travel. Short travel ranges can restrict or cancel the

limit switch adjustment range.

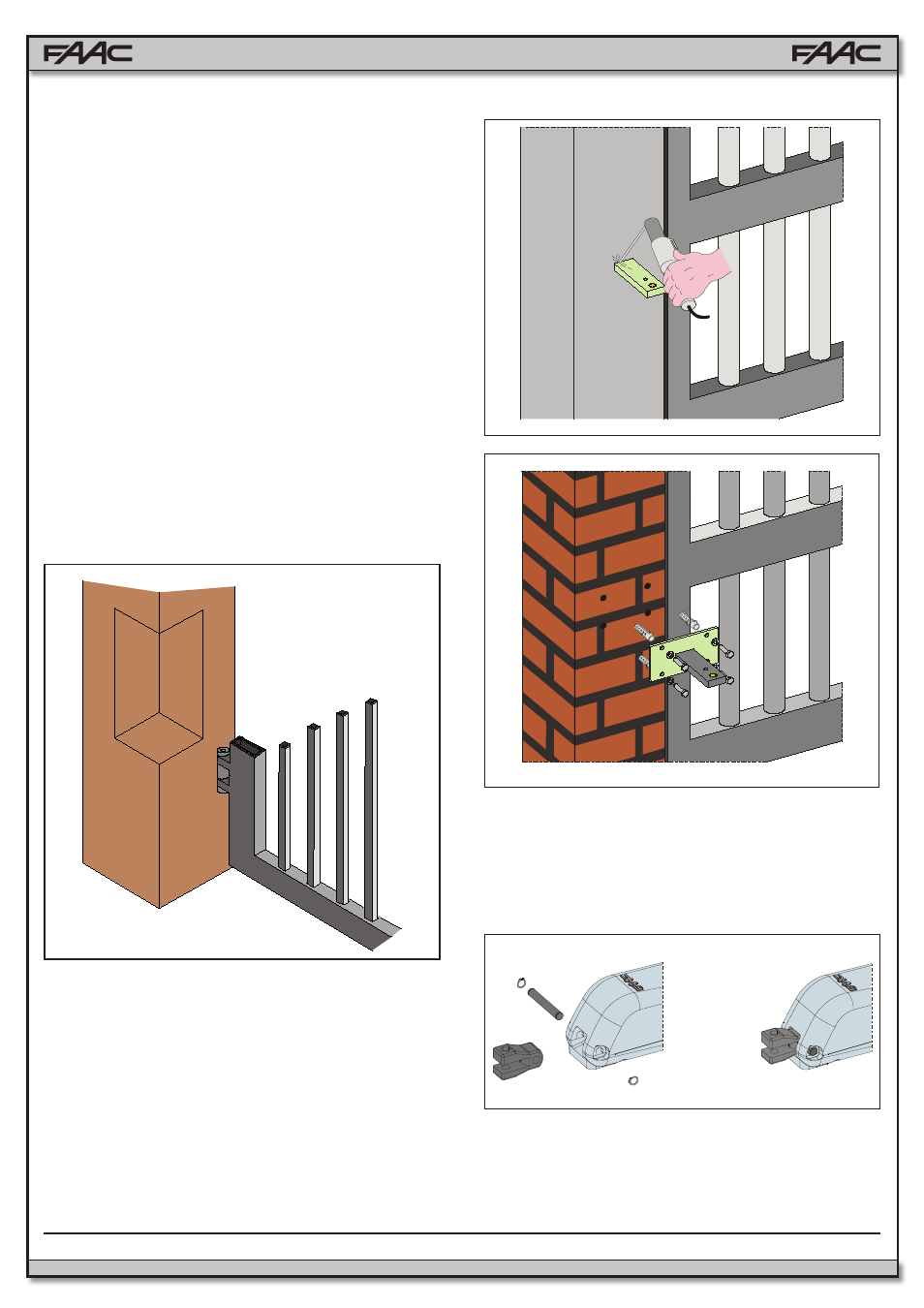

If pillar dimensions or hinge position do not allow installa-

tion of the operator, cut a niche into the pillar (as shown in

Fig. 5) in order to maintain the

A dimension as determined.

The dimensions of the niche should enable easy installa-

tion, rotation and operation of the release device.

4.4. Installing the Operator

1. Fix the rear bracket in the position you previously deter-

mined in Section 4.3.1.

• For iron pillars, carefully weld the bracket directly onto

the pillar (Fig. 6).

• For masonry pillars, use a suitable plate (optional) for

which to attach the unit (Fig. 7). Make use of a suitable

fastening system. Then carefully weld the bracket to the

plate.

While fastening the bracket, use a level to ensure that it

is perfectly horizontal.

2. Assemble and attach the rear fitting to the operator (Fig.

8).

3. Set the 415 Operator to manual operation (see Section 6).

4. Completely extend the rod until it reaches the limit stop

(Fig. 9, Ref. 1).

5. Re-lock the operator (see Section 6.1).

8

FAAC Model 415 L LS 24V Swing Gate Operator

Fig. 5

Fig. 7

Fig. 6

Fig. 8