3 product application, 1 final calibration, Roduct – Cleveland Motion Controls ULTRA ISC CANTILEVER TRANSDUCER CLTSCM REV AA User Manual

Page 20: Pplication, Inal calibration

U

LTRA

S

ERIES

ISC

C

ANTILEVER

T

RANSDUCER

T

ECHNICAL

M

ANUAL

MAN-70445-0

R

EV

AA

3

P

RODUCT

A

PPLICATION

The Ultra Series ISC Cantilever Cell Transducer utilizes a twin sensing beam. Conversion from mechanical

strain to an electrical signal is accomplished using semiconductor-based, piezoresistive strain gage

elements. The Full Wheatstone Bridge configuration provides an electrically balanced output yielding twice

the amount of signal swing as half-bridged transducers operated at the same excitation voltage. Integral

span compensation is used to correct for temperature induced gain changes.

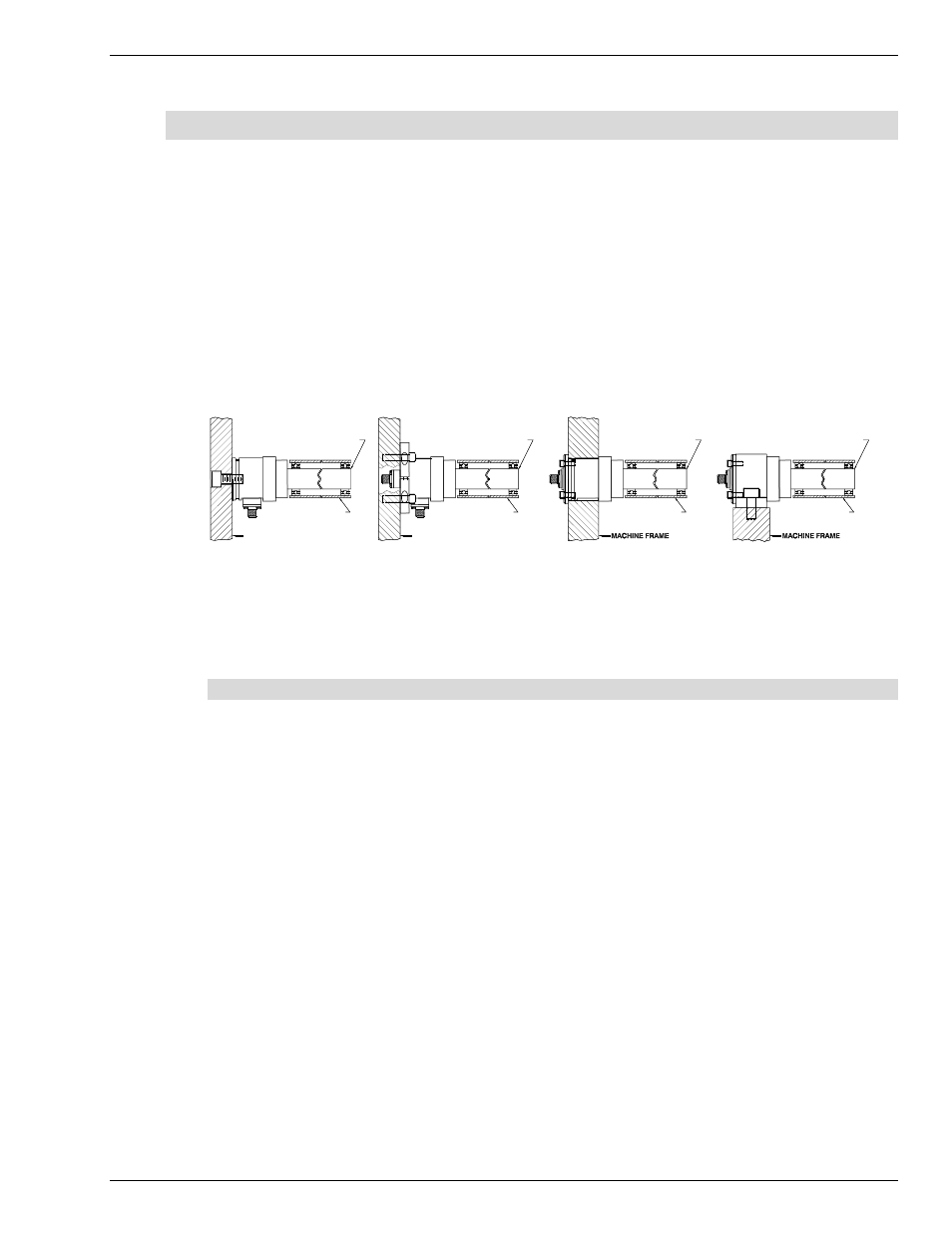

Ultra Series ISC Cantilever Cell Transducers can be mounted four different ways: Flange (FL), Stud (S), Pillow

Block (PB) and Bearing (BB) that incorporate their own low friction bearings.

Although this figure represents mounting types for the Ultra Cantilever Transducer, the

same types of mounting configurations are also applicable to Ultra ISC Cantilever transducers..

TYPE "S"

MOUNTING

TYPE "PB"

MOUNTING

TYPE "FL"

MOUNTING

STATIONARY/DEAD SHAFT

SENSING ROLL

TYPE "BR"

MOUNTING

MACHINE FRAME

MACHINE FRAME

STATIONARY/DEAD SHAFT

STATIONARY/DEAD SHAFT

STATIONARY/DEAD SHAFT

SENSING ROLL

SENSING ROLL

SENSING ROLL

Figure 7 Cantilever Cell Transducer Mounting Types

The Ultra ISC has been developed for those customers who desire to send the transducer signal directly into

their Controller, PLC, PAC, Drive, or Local I/O. It is responsibility of the customer to write this

software.

3.1 F

INAL CALIBRATION

When calibration is done though application software within the target controller, the greatest calibration

accuracy is achieved though the use of individual gain and offset parameters for each of the two transducers

(which generally are used in pairs). By using separate analog inputs and separate gain and offset

parameters, you can correct for any transfer function differences arising from subtle mounting variations

intrinsic to transducer output variations. If however the load cells are summed first and then digitized, the

matching of load cell outputs (as affected by such things as load cell orientation relative to the wrap angle)

becomes more critical.

The tradeoff between hardware cost and accuracy will impact the decision as to which approach users

decide to take.

12