Caution – Gardner Bender HYDRAULIC HAND PUMPS AND CYLINDERS User Manual

Page 4

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When

question of warranty claim arises, send the unit to the

nearest GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center. The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160

FAX (414) 352-2377

RPS-0070 Rev. A

03/07

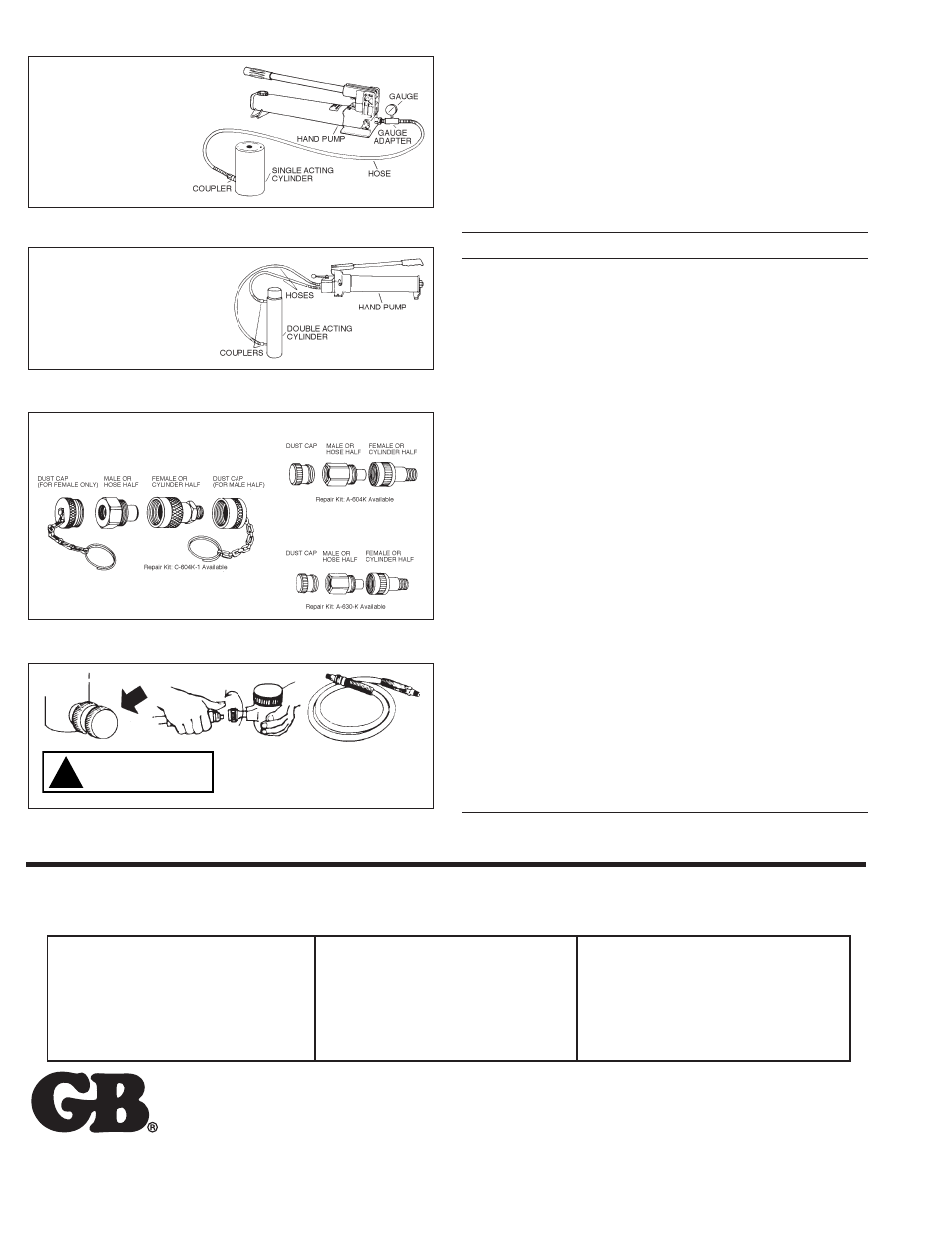

Figure 13

Connecting a Single-Acting Cylinder to a Hand Pump

Figure 14

Connecting a Double-Acting Cylinder to a Hand Pump

Figure 15

Couplers

Figure 16

Keeping Oil Lines Clean

TROUBLESHOOTING

1. Advance the hydraulic cylinder into its fullest extension. If the cylinder

does not fully advance, refer to Problems No. 1 and 2 below.

2. After the cylinder is advanced, continue to pump until the gauge shows

approximately 3,000 PSI of hydraulic pressure. If 3,000 PSI cannot be

obtained, refer to Problem No. 5 below.

3. After 3,000 PSI is obtained, put your hydraulic system into the hold

position. If the pressure drops rapidly, refer to Problem No. 5 below.

PROBLEM

POSSIBLE CAUSE

1.

Cylinder will not

A. Pump release valve open

advance

B. No oil in pump

C. Air bound

D. Couplers not fully tightened

E. Blocked hydraulic line

F. Pump not operating

2.

Cylinder advances

A. Oil level in pump is low

part way.

B. Cylinder plunger binding

C. Air trapped in cylinder

3.

Cylinder advances

A. Air in hydraulic system

in spurts

B. Cylinder plunger binding

4.

Cylinder advances

A. Leaking connection

slower than normal

B. Restricted hydraulic line or fitting

C. Loose coupler

D. Pump malfunctioning

5.

Cylinder advances

A. Cylinder seals leaking

but will not hold

B. Leaking connection

pressure

C. Pump malfunctioning

D. Incorrect system set-up

6.

Cylinder leaks oil

A. Worn or damaged seals

B. Loose connection

C. Internal cylinder damage

7.

Cylinder will not

A. Pump release closed

retract or retracts

B. Coupler not fully closed

slower than normal

C. Blocked hydraulic line

D. Broken retraction spring

E. Pump reservoir over-filled

F. Cylinder damaged internally

8.

Cylinder will not

A. Weak retraction spring

fully retract

B. Pump reservoir over-filled

C. Partially blocked hydraulic line

D. Damaged internally or externally

Hand Pump – Two-way Release Valve

Hose – One required

Coupler – Male half coupler on hose

Single-Acting Cylinder – Hydraulic

force in one direction only. Female

half coupler on cylinder.

Hand Pump – Four-Way Valve

(Pump Mounted)

Hose – Two required

Coupler – Male half coupler on each hose

Double-Acting Cylinder – Hydraulic force

in advance and retract. Two female half

couplers on cylinder.

3

/

8

" HIGH FLOW COUPLER

3

/

8

" REGULAR COUPLER

1

/

4

" COUPLER

Dirt and foreign matter may cause pump, cylinder,

or valve failure. Use every precaution to guard

against entrance of dirt. When coupler halves are

disconnected, always screw on dust caps.

!

CAUTION