Gardner Bender HYDRAULIC HAND PUMPS AND CYLINDERS User Manual

Page 3

2. Operate pump handle.

3. To retract cylinder plunger, turn release valve counterclockwise as

illustrated in Figure 7.

4. Pumps can be operated while they are horizontal or vertical as long as

the hose end is down.

MAINTENANCE

1. To check oil level in pump, open pump release valve to allow oil in

cylinder (if connected) to return to pump.

2. Remove fill cap and add GB/ENERPAC hydraulic oil until level with

mark on rear cap. DO NOT overfill. To function properly, all hand

pumps require air in the reservoir. If oil level is too high, the pump will

not operate.

3. If hydraulic system is used under extremely dirty conditions, frequently

drain pump completely.

4. Refill with clean GB/ENERPAC hydraulic oil.

5. Install fill cap and close it.

REPLACING COUPLERS

To assemble to hose:

1. Clamp the hexagon nut of the hose fitting in a vise as illustrated in

Figure 9.

2. Remove the old coupler or rigid adapter.

3. Install the new coupler clockwise onto

hose fitting to a firm fit. Use high quality

thread sealer on threads (one wrap only).

A kit has been prepared for the purpose of

replacing a worn out seal and may be

obtained at your nearest GB Authorized

Service Center.

To assemble Spee-D-Couplers to cylinder:

1. Use wrench to unscrew old coupler half

from cylinder.

2. thread new coupler to cylinder and tighten

firmly. Use a high quality thread sealer on

coupler threads (one wrap only).

HYDRAULIC CYLINDERS

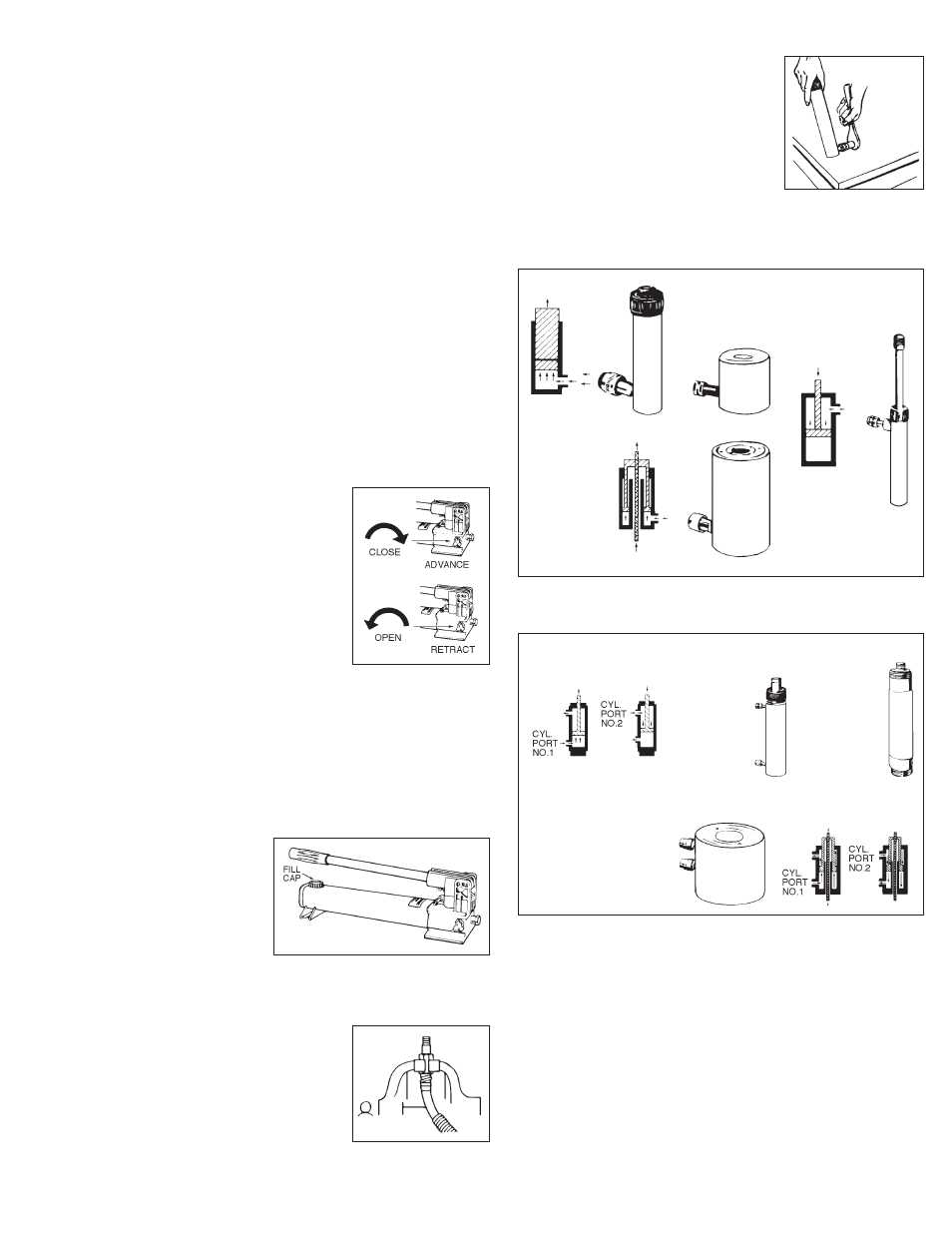

Figure 11

Single-Acting Hydraulic Cylinders

Figure 12

Double-Acting Hydraulic Cylinders

GENERAL INSTRUCTIONS

GB cylinders are designed for full rated capacity over the full plunger

travel. Refer to current GB catalog for capacity.

OPERATIONAL INSTRUCTIONS

Hydraulic Connections – All hydraulic cylinders must be properly

connected to the hydraulic pump to function. Always use thread sealer on

connections; i.e., teflon tape or equivalent. Figures 13 and 14 show the

basic connections of hydraulic cylinders to pumps.

Figure 7

Release Valve Positions

Figure 8

Location of Fill Valve

Figure 9

Assembling to Hose

Figure 10

Assembling Couplers to Cylinder

PUSH TYPE

• Hydraulic Advance

• Spring Retract

PUSH or

PULL TYPE

HOLLOW

PLUNGER

• Hydraulic

Advance

• Spring Retract

PULL TYPE

• Hydraulic Retract

• Spring Advance

GENERAL

PURPOSE

• Hydraulic Push

• Hydraulic Return

PUSH AND PULL TYPE

HOLLOW PLUNGER

• Hydraulic Advance

• Hydraulic Retract

PUSH AND PULL TYPE

PRECISION

MODELS

• Hydraulic Push

• Hydraulic Pull