Flowline LC30 Thermo-Flo User Manual

Page 13

Rev A

LC900008

13 of 14

APPENDIX

Step Nine

Controller Logic: Please use the following guide to understand the operation of the controllers.

1. Power LED: Make sure the Green power LED is ON when power is supplied to the controller.

2. Input LED: For NC switch wiring, the input LED on the controller will be Amber when the switch reads no‐

flow and OFF when the switch reads flow.

3. Invert Operation: When the input LED turn Off and On, the relay LED will also switch. With invert Off, the

relay LED will be On when the input LED is On and Off when the input LED is Off. With invert On, the relay

LED will be Off when the input LED is On and On when the input LED is Off

.

4. Relay Operation: The relay may be wired either NO or NC. The normal state of the relay is when its LED is

Off. With the LED On, the relay is in the energized mode and all terminal connections are reversed.

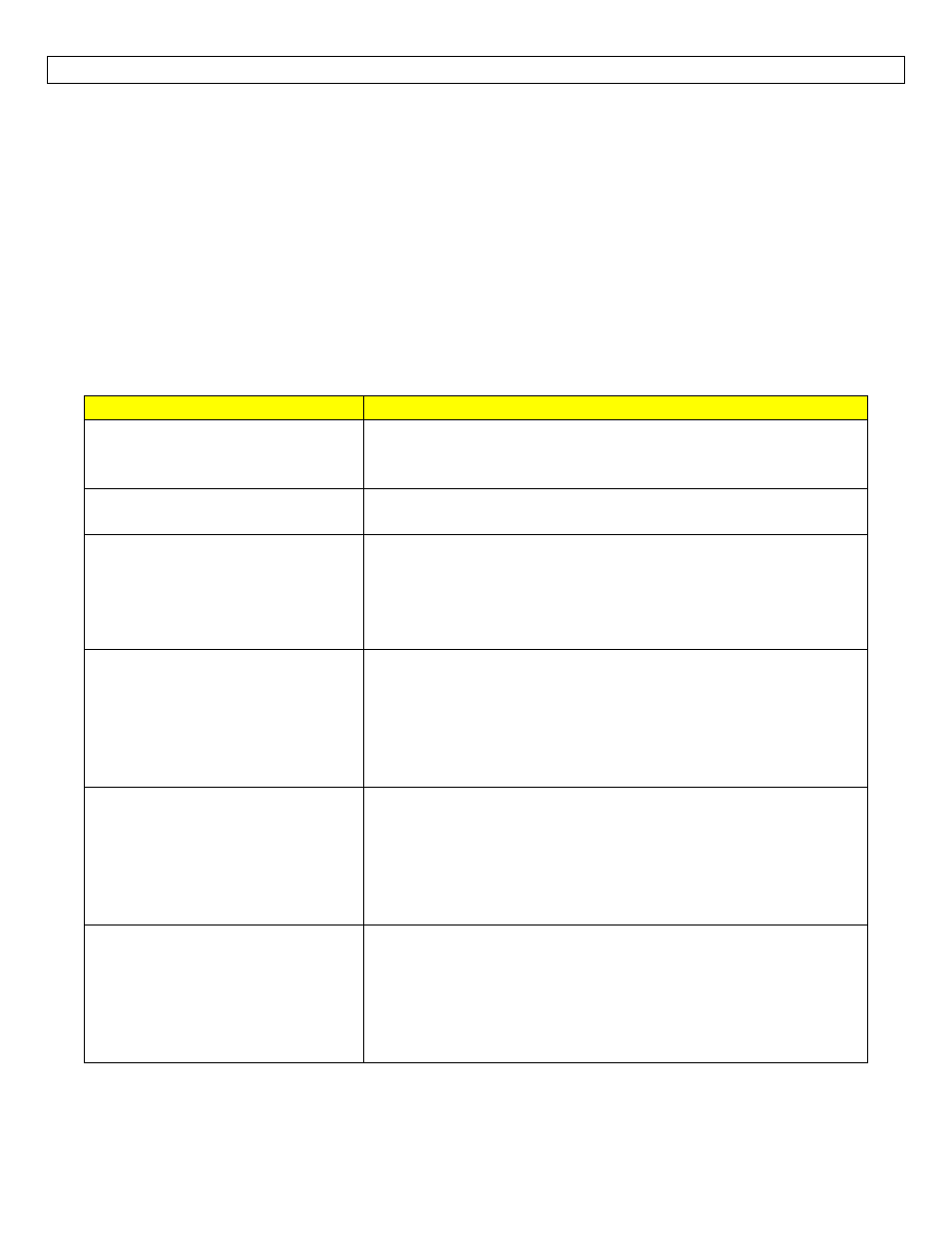

Troubleshooting:

PROBLEM

SOLUTION

Controller is powered, but nothing

happens.

First check the Power LED to make sure it is Green. If not, check

the wiring, power and make sure the terminal is seated

correctly over the 6‐pins.

A Flow or No‐Flow condition is

met but the relay did not switch.

Check the relay by switching the invert switch. Confirm that

relay click on and off as well as the relay LED.

The Flow or No‐Flow is not

switching at the correct flow rate.

The flow switch may need to be adjusted. Review the Flow

Switch Calibration section on the previous page for instructions

on setting the actual flow switch. Note: access to the flow

switch adjustment is difficult and requires the removal of the

PCB assembly. Use caution when performing this step.

Trying to start the flow but the

controller keeps turning the flow

off.

To restart a flow condition, the sensor needs to sense an actual

flow condition before changing the relay in the controller. A

flow switch over‐ride may need to be added across the relay

contacts that allows for a true flow to occur before switching

back to the controller. The use of a moment switch is

recommended for the over‐ride switch.

Relay LED does not match my flow

condition.

The relay LED can be switched by either the reversing the wiring

of the sensor to the controller or by flipping the invert switch.

This means that the relay LED can either be set to turn on

during a flow condition or to turn off during a no‐flow

condition. This is all dependent on the wiring and the invert

position.

Relay LED does not match the

sensor’s LED indicator.

The sensor’s LED will always be ON during a No‐Flow state and

OFF during a Flow state, regardless of the switches wiring. As

per above the input LED can be inverted to any condition. In

some applications, they will match and in others they will be

opposite. This is all dependent on the application

parameter/setup.