Pipe insulation, Filling the system, 7 filling the system – DE DIETRICH NEO 2.1 User Manual

Page 69

4.6.3.

Pipe insulation

CAUTION

To protect the insulation against mechanical damage, bird

pecking and UV light, add extra protection for the heat

insulation sleeves in the roof area by using an aluminium

sheet sleeve or aluminium adhesive tape. This additional

protection must be sealed with silicone.

4

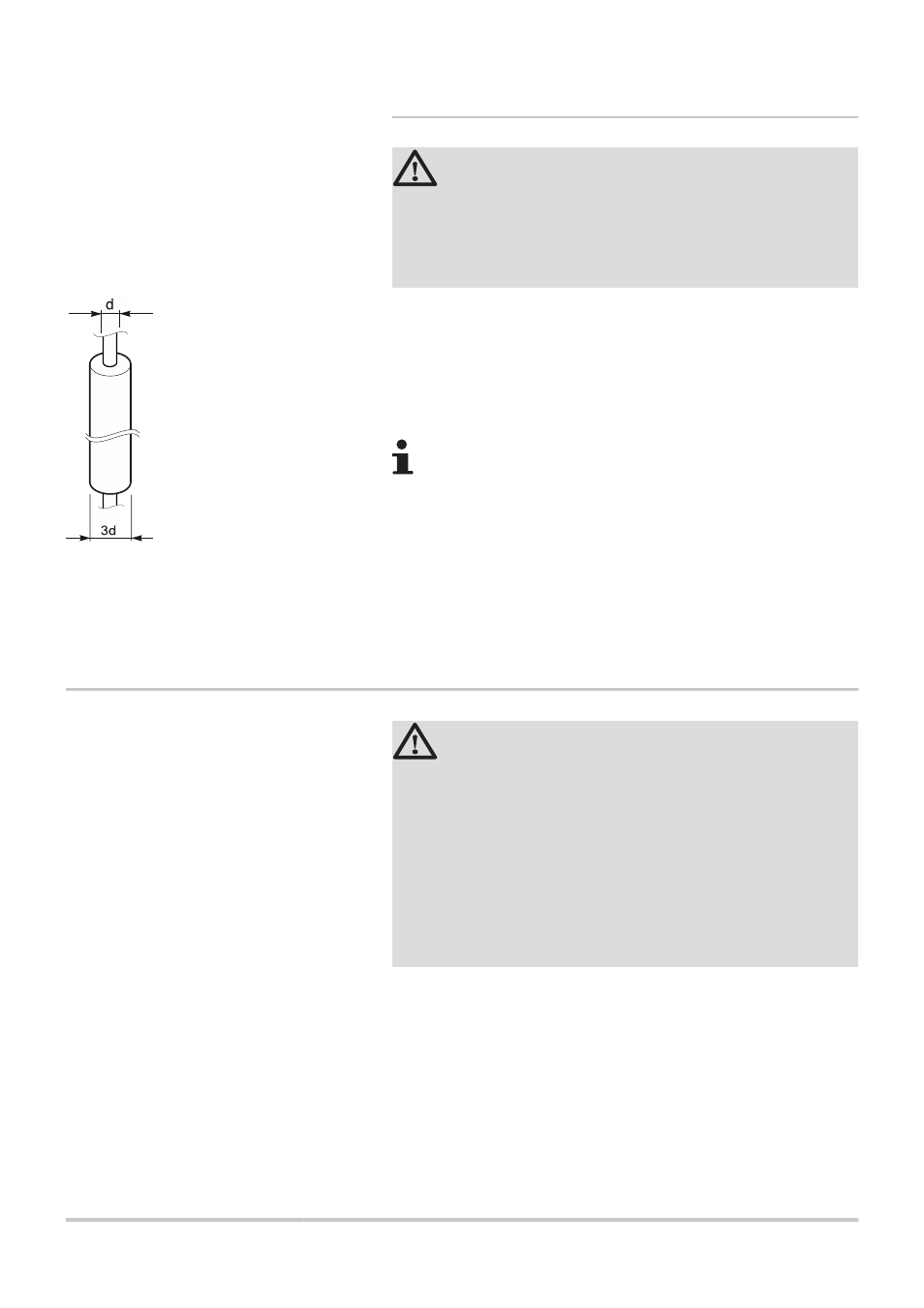

If different copper pipes are used, the insulation must be:

-

Resistant to constant temperatures up to 150 °C in the collector

zone and the hot outlet and also down to - 30 °C.

-

Insulation preferably waterproof and continuous.

-

with a thickness equal to the tube diameter and with a K

coefficient of 0.04 W/mK.

50 % reduction of the insulation is permitted when passing

through the roof and walls.

4

Recommended materials for temperatures up to 150 °C:

-

Duo-Tube

-

DuoFlex

-

Armaflex HT

-

mineral wool

-

glass fibre

4.7

Filling the system

CAUTION

4

Do not fill / rinse a hot solar collector. Risk of being

burnt.

4

Before the filling of the installation, to check the

preload of the expansion vessel according to the

static height (Preload = static Height/10 + 0.3 bar).

4

check the connection to the series of collectors and

the collector sensor connection.

4

Since propylene glycol leaks much more easily than

water, check all connections and gaskets for leaks

after a few hours of operation at working pressure.

Following installation of the solar panels and hydraulic connection of

the panels and piping, the system can undergo pressure tests and be

filled. When doing so, the thermal conditions and the particular

features of the installation must be taken into account. For that

reason, the system may only be filled, commissioned and maintained

by a suitably authorised technician.

Bring the pressure in the primary solar circuit up to the 2 bar working

pressure by topping up if necessary with heat transfer fluid.

M001704-A

NEO 2.1 / SUN 211

4. Installation

20/02/2013 - 300024195-001-02

68