Hydraulic connections, Connection dimensions, Connecting – DE DIETRICH NEO 2.1 User Manual

Page 68: 6 hydraulic connections

4.6

Hydraulic connections

4.6.1.

Connection dimensions

Number of panels Size

(mm)

Maximum length

(Outlet + Return)

2

14-15 40 m

3

14-15 40 m

4

16-18 40 m

5

16-18 40 m

To be able to have pipework without degassers or bleed valves at

high points, the solar fluid flow rate must not fall below 0,4 m/s during

the degassing procedure.

The pipes must be as short as possible and always sloping

downwards between the collectors and the connection to the solar

calorifier.

If the installation criteria for good degassing cannot be met, a manual

bleed degasser R must always be installed at the high point(s) of the

solar equipment.

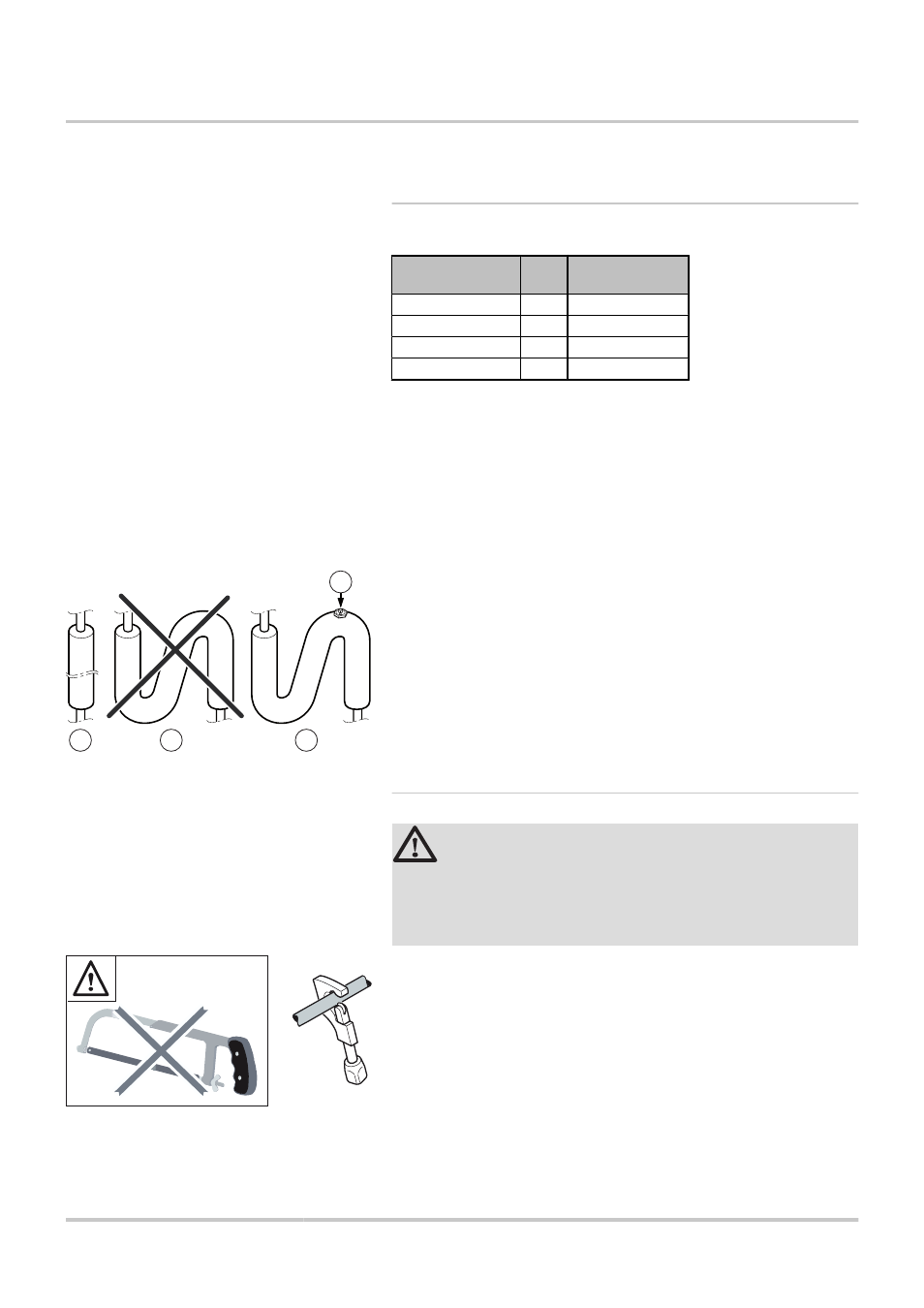

A

Ideal

Z

Incorrect (high point with no air vent)

E

Correct (high point with air vent)

R

Location of manual bleed valve degasser

4.6.2.

Connecting

CAUTION

Soft soldering are not authorized.

The use of flux promotes corrosion conditions in systems

operating with propylene glycol as heat transfer fluid. In all

cases the inside of the pipes must be flushed.

4

Use of a hacksaw is prohibited.

4

Pipe connections by compression unions.

4

Hard soldering: Hard soldering: hard soldering filler metal without

flux in accordance with DIN EN 1044, e.g. L-Ag2P or L-CuP6.

4

Pipe unions: can only be used if they are resistant to glycol,

pressure (6 bar) depending on version) and temperature (-30 °C,

180 °C) (manufacturer’s data).

4

Sealing material: Hemp.

4

Press fitting (6 bar, 140 °C).

1

2

3

4

M001755-A

M001756-A

4. Installation

NEO 2.1 / SUN 211

67

20/02/2013 - 300024195-001-02