4 gas settings, 1 changing the burner injectors, 2 changing the ignition burner injector – DE DIETRICH ELITEC DTG 130 Eco.Nox User Manual

Page 25

25

01/02/11 - 300002915-001-E

DTG 130 Eco.NOx

5.4 Gas settings

DTG 130 Eco.NOx boilers are delivered preset for operation on

natural gases of H/E groups.

For operation on another group of gases, carry out the following

operations.

These actions must be carried out by a qualified

technician.

5.4.1

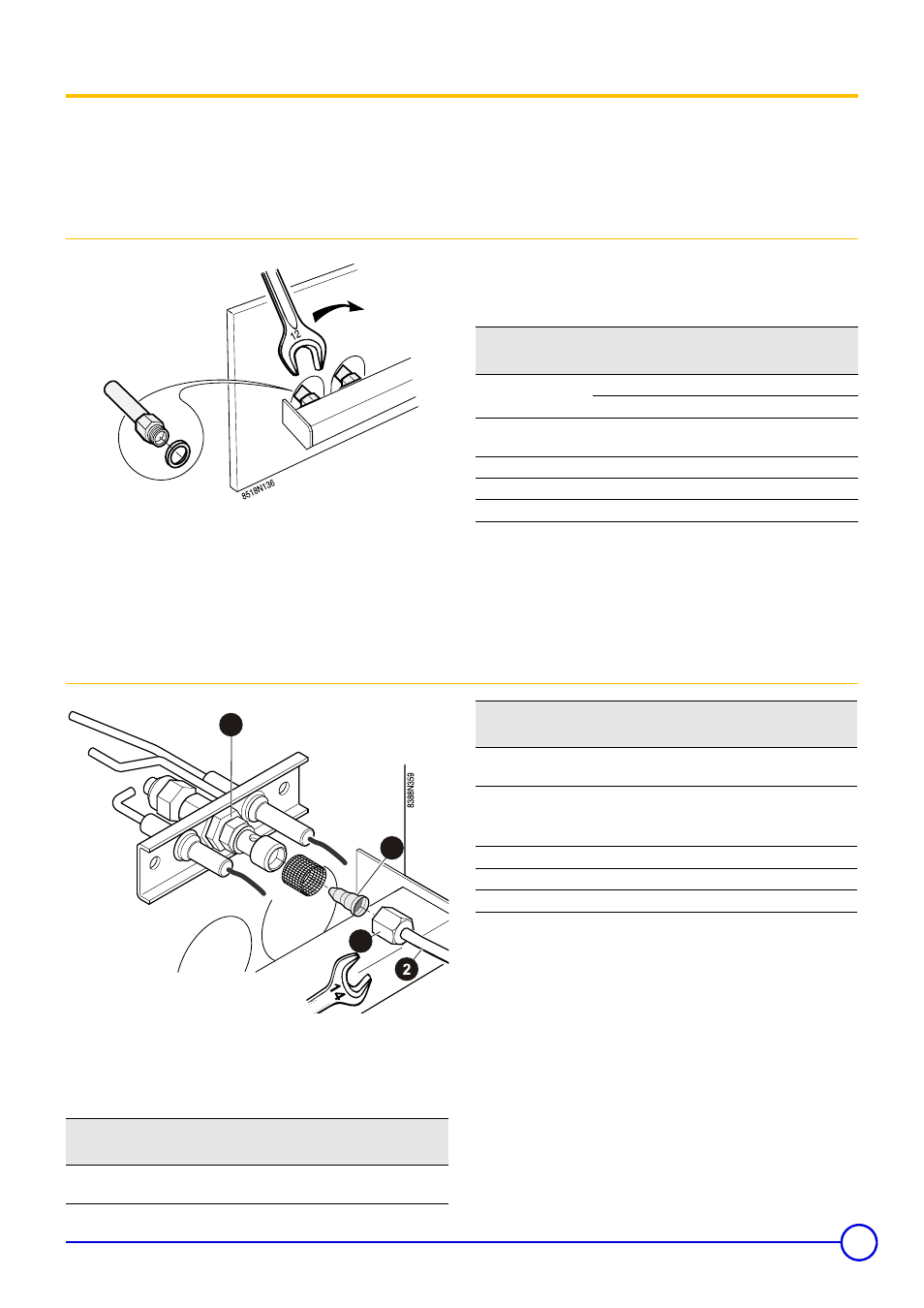

Changing the burner injectors

Cut the electricity and gas supply to the boiler.

Lift out the injector with a number 12 spanner assemble the new

injectors with their new joint.

Reassembly:

Correctly replace the seals.

First tighten the injectors by hand and carefully lock them using

a spanner.

Carry out a gas tightness check

5.4.2

Changing the ignition burner injector

Unscrew the connecting nut (14 spanner)

Pull the gas supply pipe towards yourself

Take out the ignition burner nozzle

Fit the new nozzle

Re-attach the supply tube (14 spanner)

Carry out a gas tightness check.

Models DTG

Nozzle

marking

Nozzle

diameter (mm)

Natural gas H/E

GZ50

133 to 137

204B

2.04

138 to 139

210B

2.10

Natural gas L/LL

GZ410

245B

2.45

Propane

140A

1.40

H - 13 mbar

225B

2.25

GZ350

310B

3.10

Nozzle marking

Nozzle diameter

(mm)

Natural gas H/E

GZ50

4

0.40

1

3

4

Natural gas L/LL

(France)

4

0.40

Natural gas L/LL

(

≠

France)

GZ410

5

0.50

Propane

3

0.30

H - 13 mbar

4

0.40

GZ350

6

0.60

Nozzle marking

Nozzle diameter

(mm)