AAON M2-036 User Manual

Page 79

79

Electric Heating

Set thermostat in the heat mode; call for heat

to engage all electric heat strips. Check

blower for proper rotation and voltage.

Measure the amperage and voltage.

Compare them to the nameplate data.

If applicable, check remote heat pump

condenser as per the manufacturer’s

recommendations.

Steam or Hot Water Heating

Set thermostat in the heat mode. Observe

supply blower for proper rotation and

voltage. Check boiler or hot water operation

according to the manufacturer’s instructions.

Check control flow valves for correct

operation and settings per the

manufacturer’s instructions.

Cleaning

Inspect and clean unit interior at the

beginning of each heating and cooling

season and as operating conditions require.

Chilled Water

Check remote chiller operations as per the

manufacturer’s instructions. Check coolant

flow valves for correct operation and

settings.

Lubrication

Most motors and bearings are permanently

lubricated. Some applications may require

that bearings be re-lubricated periodically.

The schedule will depend on the operating

duty, temperature variations, and other

atmospheric conditions.

For bearings equipped with lubrication

fittings, the lubrication schedule is

dependent on operating temperatures and

rotational speeds as shown in the table

below. Lithium based grease conforming to

an NLGI grade No. 2 consistency is

recommended. This medium viscosity, low

torque grease is rust inhibiting and water-

resistant. It is satisfactory for operating

temperatures in the range of –10

°F to 250°F.

Bearings should only be re-lubricated when

at normal operating temperatures and not

running. Rotate the fan shaft by hand,

adding only enough grease to purge the

seals. A one-inch bearing has a total grease

capacity of only .25 ounces. Added grease

should be limited to .09 ounces.

Do Not Over Lubricate!

Recommended greases are:

SHELL OIL - DOLIUM R

CHEVRON OIL - SRI No. 2

TEXACO INC. - PREMIUM RB

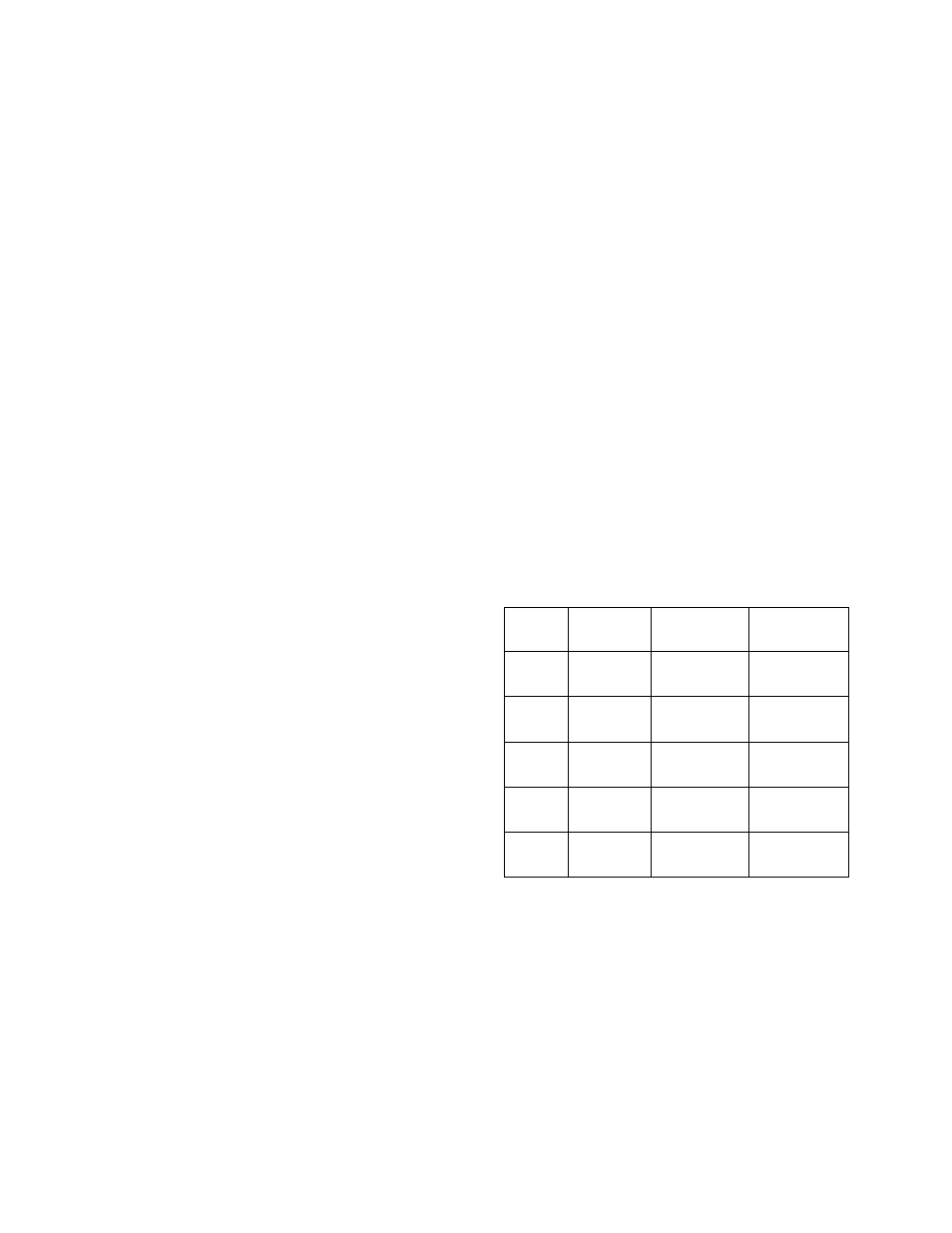

Table 16 - Fan Bearing Lubrication

Schedule

Fan

Speed

Temp. Environ.

Greasing

Interval

500

rpm

Up to

150

°F

Clean

2 to 6

months

1000

rpm

Up to

210

°F

Clean

2 weeks to

2 months

1500

rpm

Up to

210

°F

Clean Monthly

Any

Speed

Up to

150

°F

Dirty

1 week to

1 month

Any

Speed

210 -

250

°F

Dirty Weekly

In the event the unit is not functioning

correctly and a service company is required,

only a company with service technicians

qualified and experienced in both

commercial heating and air conditioning

should be permitted to service the systems in

order to keep warranties in effect. The

service tech may call the factory if

assistance is required.