AAON M2-036 User Manual

Page 78

78

Cleaning

The need for cleaning of the wheel will be

determined by the operating schedule,

climate and regular contaminants of the

conditioned space. The AAONAIRE

®

Heat

Wheel is “self-cleaning” in that the smallest

particles will pass through and larger

particles will land on the wheel surface and

will then be blown clear as the wheel rotates

into the opposite direction of laminar flow.

The primary cleaning need will be to

remove oil based aerosols that have

condensed on energy transfer surfaces.

These oily films can clog micron sized pores

in the desiccant material reducing the

wheel’s efficiency. It can take several years

in a reasonably clean environment such as a

school or an office building, for measurable

efficiency loss to occur. Dirtier air, such as

that from a kitchen, industrial or machine

shop or a smoke filled room, will reduce

efficiency in a much shorter period of time.

To clean the wheel, remove the segments

from the wheel frame, and brush foreign

material from the face. Soak the segments in

a non-acid based coil cleaner, or another

alkaline detergent, and warm water.

Massaging the matrix with your hands will

increase the cleaning action. Rinse well, and

shake excess water away before reinstalling.

For applications where frequent cleaning is

required, it is advisable to keep a second set

of wheel segments on hand. While a set is

soaking, or being cleaned, the spare set can

be replaced in the wheel.

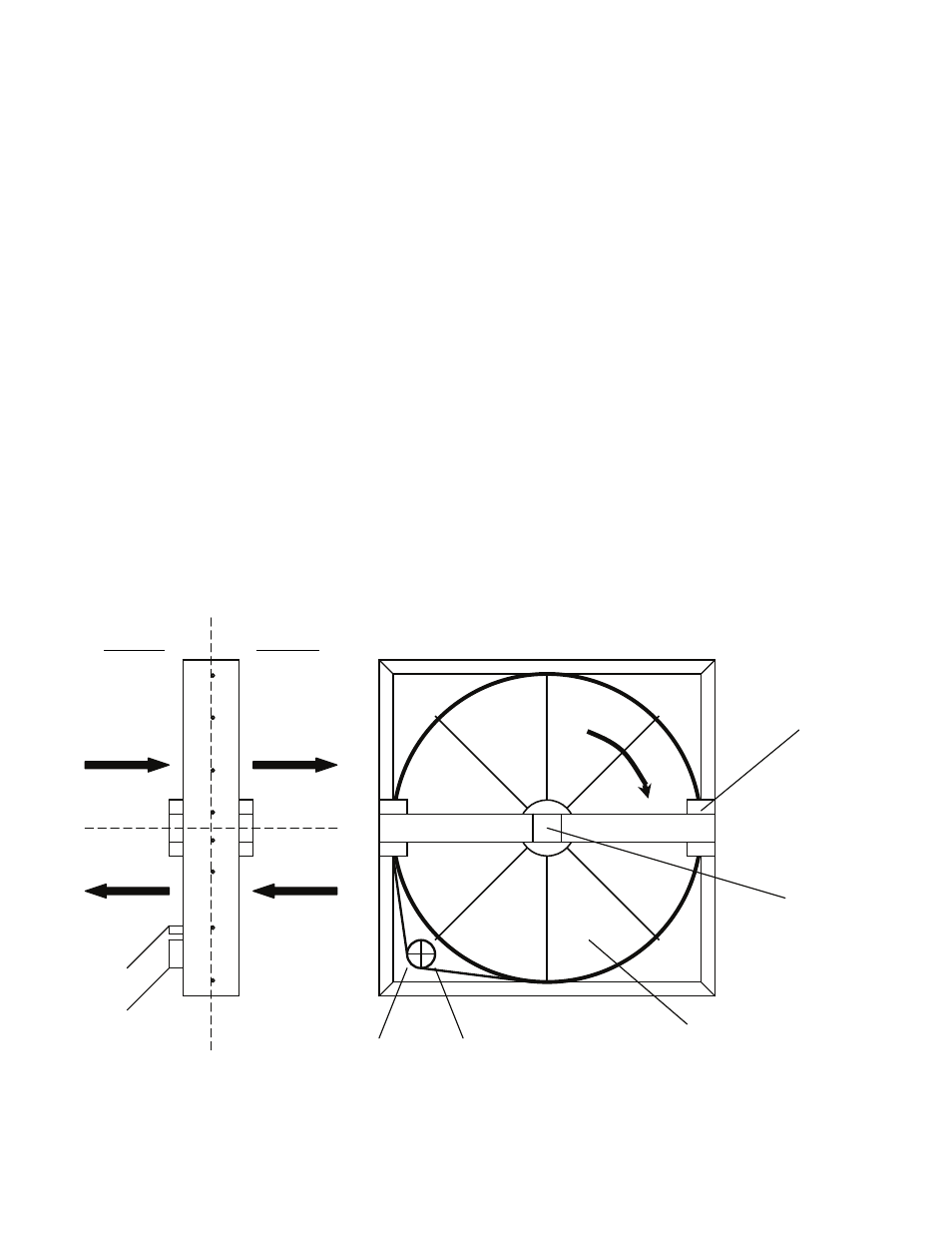

Figure 31 - Energy Recovery Wheel

Rim Diameter Seal

Bearing Access Cover

Pulley Drive

Belts

Energy Recovery

Wheel with 8

Removable Segments

Capacitor

P.C.S. Motor

Outdoor Air

Fresh Air Supply

Indoor Air

Exhaust Air

“Pulley Side” View

Rotation

Motor Side Pulley

Side