Warning – AAON M2-036 User Manual

Page 49

49

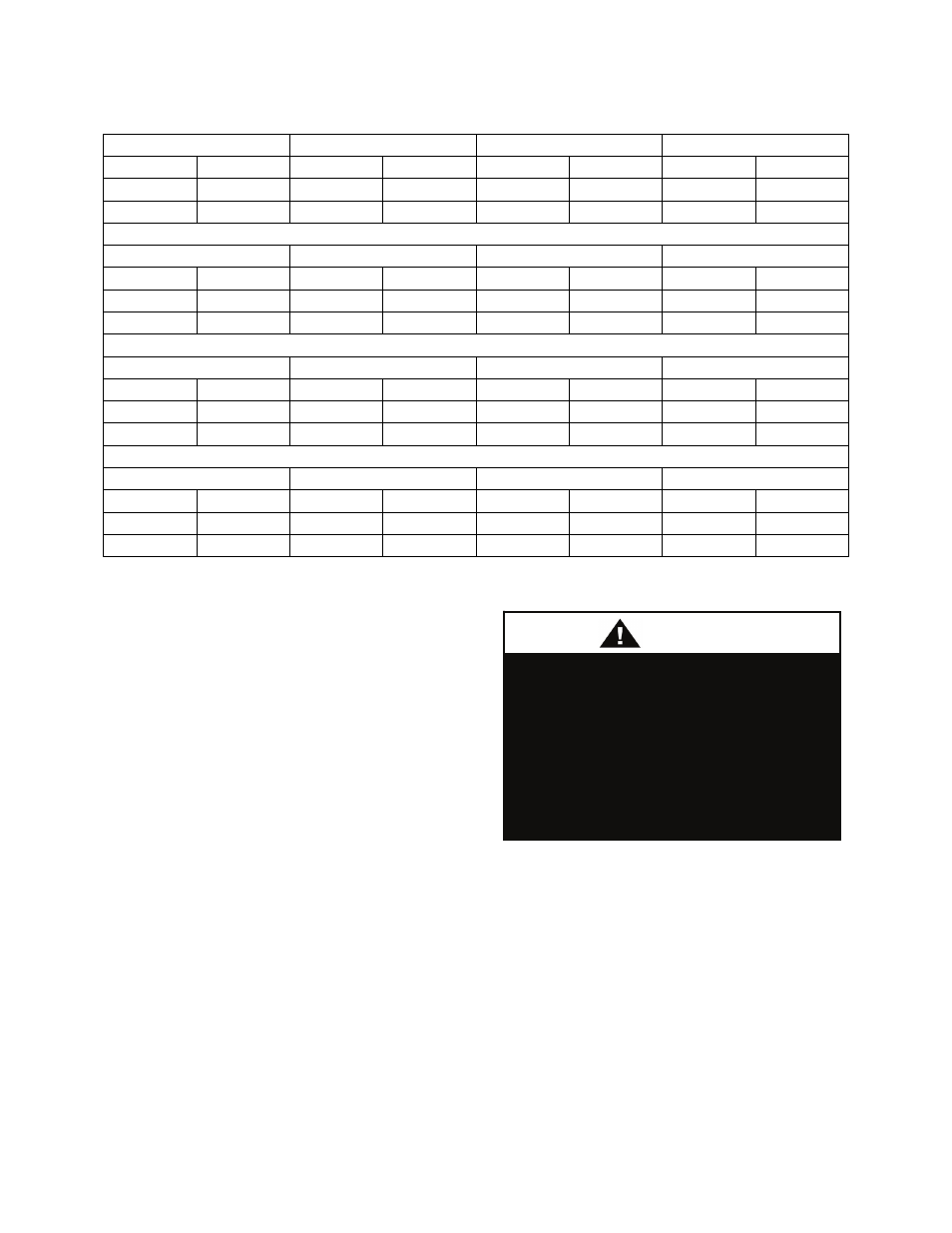

Table 5 - Brazed Plate Heat Exchanger Pressure Drops (WCC- & WHP-)

-003 -004 -005 -006

gpm psi gpm psi gpm psi gpm psi

7.9 2.89 10.0 4.41 12.5 5.46 15 2.37

9.5 4.03 12.1 6.21 15.1 7.69 18.1 3.39

-006 -008 -010 -013

gpm psi gpm psi gpm psi gpm psi

17.5 3.17 20.0 2.91 25.0 3.34 32.5 4.3

21.1 4.55 24.1 4.71 30.2 4.79 39.2 6.17

-016 -020 -025 -030

gpm psi gpm psi gpm psi gpm psi

40.0 4.26 50.0 4.72 62.5 4.92 75.0 4.75

48.3 6.11 60.4 6.77 75.4 7.06 90.5 6.82

-040 -050 -060

gpm psi gpm psi gpm psi

100.0 6.6 125.0 10.1 150.0 9.46

120.7 9.5 150.9 14.4 181.0 13.6

Water-Cooled Condenser Safeties

Electronic freeze protection and water flow

safeties should be field installed or factory

provided. If the leaving water temperature

drops below 38°F or water flow has ceased

the 24VAC control circuit will be broken to

disable the cooling system.

Electrical

Verify the unit name plate agrees with

power supply. M2 Series units are provided

with single point power wiring connections.

Connection terminations are made to the

main terminal block. A complete set of unit

specific wiring diagrams, showing factory

and field wiring are laminated in plastic and

located inside the controls compartment

door.

All units require a field supplied electrical

overcurrent and short circuit protection.

Device must not be sized larger than the

Maximum Overcurrent Protection (MOP)

shown on the unit nameplate.

Codes may require a disconnect switch be

within sight of the unit.

Note: Do not install the required field

installed overcurrent protection or

disconnect switch on the unit!

Electrical supply can enter through the

bottom or side of the controls compartment.

Entry must be field cut into panels of the

unit.

Disconnect all electrical power

sources before servicing the unit.

More than one power source may be

provided. Failure to do so may result

in injury or death from electrical

shock or entanglement in moving

parts.

WARNING