Warning – AAON M2-036 User Manual

Page 58

58

minimize the number of elbows or turns in

vent pipe.

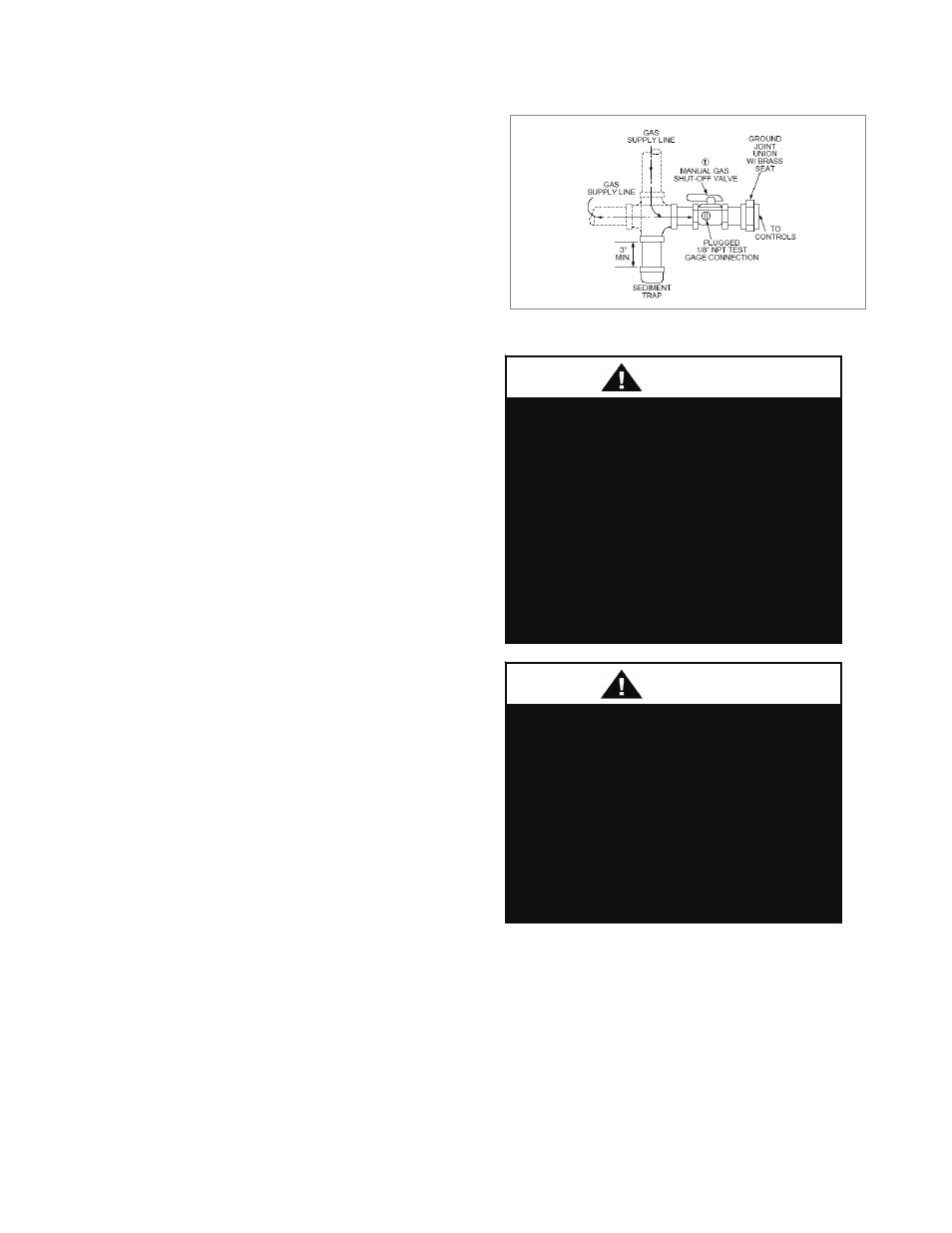

Gas Supply, Piping and Connections

Gas piping must be installed in accordance

with local codes, or in the absence of local

code, installation must conform to the

current (United States) National Fuel Gas

Code ANSI-Z223.1/NFPA 54 or the current

(Canada) National Fuel & Propane

Installation Code CSA B149.1 or B149.2.

1. Gas piping must be sized for the total Btu

input of all units (heaters) serviced by a

single supply.

2. Be sure that gas regulators servicing more

than one heater have the proper pipe and

internal orifice size for the total input of all

heaters serviced by the regulator.

3. Duct furnaces require a minimum inlet

gas pressure of 5.0 “w.c and limited to a

maximum inlet gas pressure of 13.5” w.c.,

with the furnace operating.

4. A 1/8” NPT tap is provided on the inlet

side of the gas valve to the heater. A fitting

suitable for connection to a pressure gauge

capable of measuring gas pressure should be

connected to each heater serviced by a

single regulator so that gas pressure at each

heater can be measured with all heaters in

operation.

5. A drip leg (sediment trap) and a manual

shut off valve must be provided immediately

upstream of the gas control on the heating

unit. To facilitate servicing of unit,

installation of a union is recommended.

Figure 21 - Sediment Trap

1. All field gas piping must be

pressure / leak tested prior to

operation. NEVER use an open flame

to check for leaks. Use a soap

solution or other leak detecting

solution for testing.

2. Gas pressure to appliance controls

must never exceed 13.5” w.c. (1/2

psi)

WARNING

1. When pressure testing at 1/2 psi or

less, close the manual shutoff valve

on the appliance before testing.

2. When pressure testing gas supply

line at 1/2 psi or higher, close manual

gas valve and disconnect heater from

supply line to be tested. Cap or plug

the supply line.

WARNING