AAON M2-036 User Manual

Page 75

75

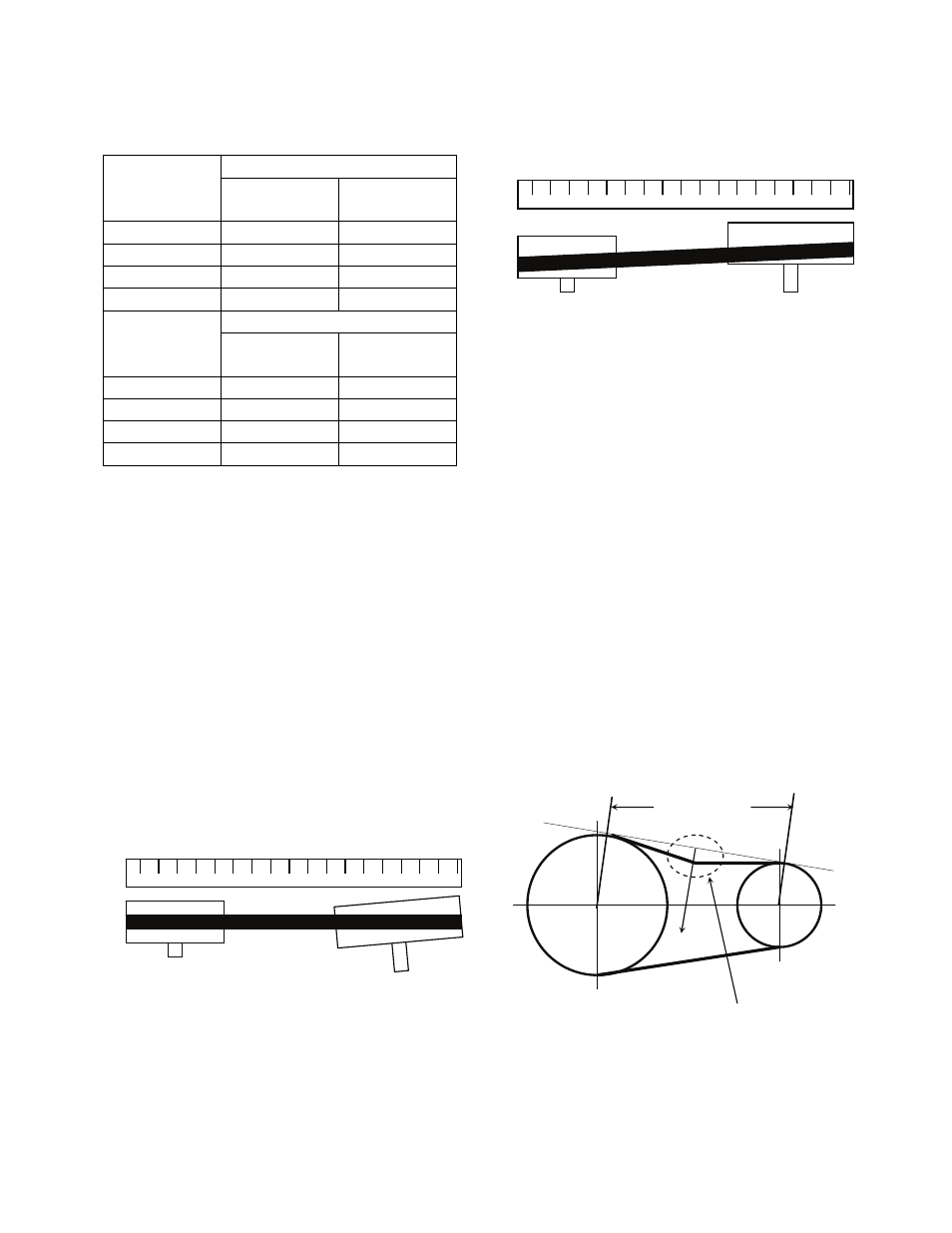

Table 15 - Bearing Setscrew Torque

Recommendations

Shaft Size

(inches)

Setscrew Locking

Thread

Torque

(in-lbs.)

1

1/4 - 28

66 - 85

1 3/16

1/4 - 28

66 - 85

1 7/16

5/16 - 24

126 - 164

1 7/8

3/8 - 24

228 - 296

Shaft Size

(inch)

Skewzloc Locking

Thread

Torque

(in-lbs.)

1

8 - 32

63 - 70

1 3/16

8 - 32

63 - 70

1 7/16

10 - 24

81 - 90

1 7/8

1/4 - 20

162 - 180

Belts

Belt drive misalignment is one of the most

common causes of premature belt failure. A

belt can be destroyed in a matter of days if

the drives have been aligned incorrectly.

The most common tool for measuring

misalignment is a straightedge. Hold the

straightedge flush across one pulley to gauge

the degree of misalignment of the two

sheaves. The maximum allowed

misalignment is one half degree of angular

misalignment, and 1/10

th

of an inch per foot

between sheave centers for parallel

misalignment.

Figure 28 - Angular Misalignment

Correct by moving the position of the motor.

Figure 29 - Parallel Misalignment

Correct by adjusting sheaves on one, or both

shafts.

Frequent belt tensioning is highly

recommended. Most belt manufacturers

would suggest a re-tensioning after as little

as 8 hours of operation. A simplified

method of adjusting tension is to gauge the

amount of force required to deflect the belt

by 1/64

th

of an inch per inch of distance

between sheave centers. For example, if the

sheaves are 20 inches apart, then the amount

of deflection with the forces listed below is

20/64

th

(5/16

th

) of an inch.

Deflection required for

“A” belts: 4-6 lbs.

“B” belts: 6-10 lbs.

“C” belts: 10-18 lbs.

Figure 30 - Belt Deflection

Sheave Centers

Force

Deflection = 1/64

th

in.

per inch of length

Straightedge

Pulley

Pulley

Belt

Straightedge

Pulley Pulley

Belt