CEMB USA C72_2SE (C) User Manual

Page 11

I 0391 -

10

I 0391 -

11

b

8

Pos B

Pos A

8a

8b

8c

8d

GB

GB

5 - Indications and use of the wheel balancer

5.1 - Double operator program

This program allows memorizing the dimensions of two types of wheels. Thus two operators can work simultaneously

on two different cars using the same balancing machine. The system memorizes two programs with various preset

dimensions.

1 - Press

to select operator (1 or 2). Selection is confirmed by panel-mounted LED.

2 - Enter the dimensions (see

PRESETTING OF WHEEL DIMENSIONS

)

3 -

carry out the balancing as usual.

With

program 1 or 2 is called for subsequent balancing operations without having to newly enter the

dimensions.

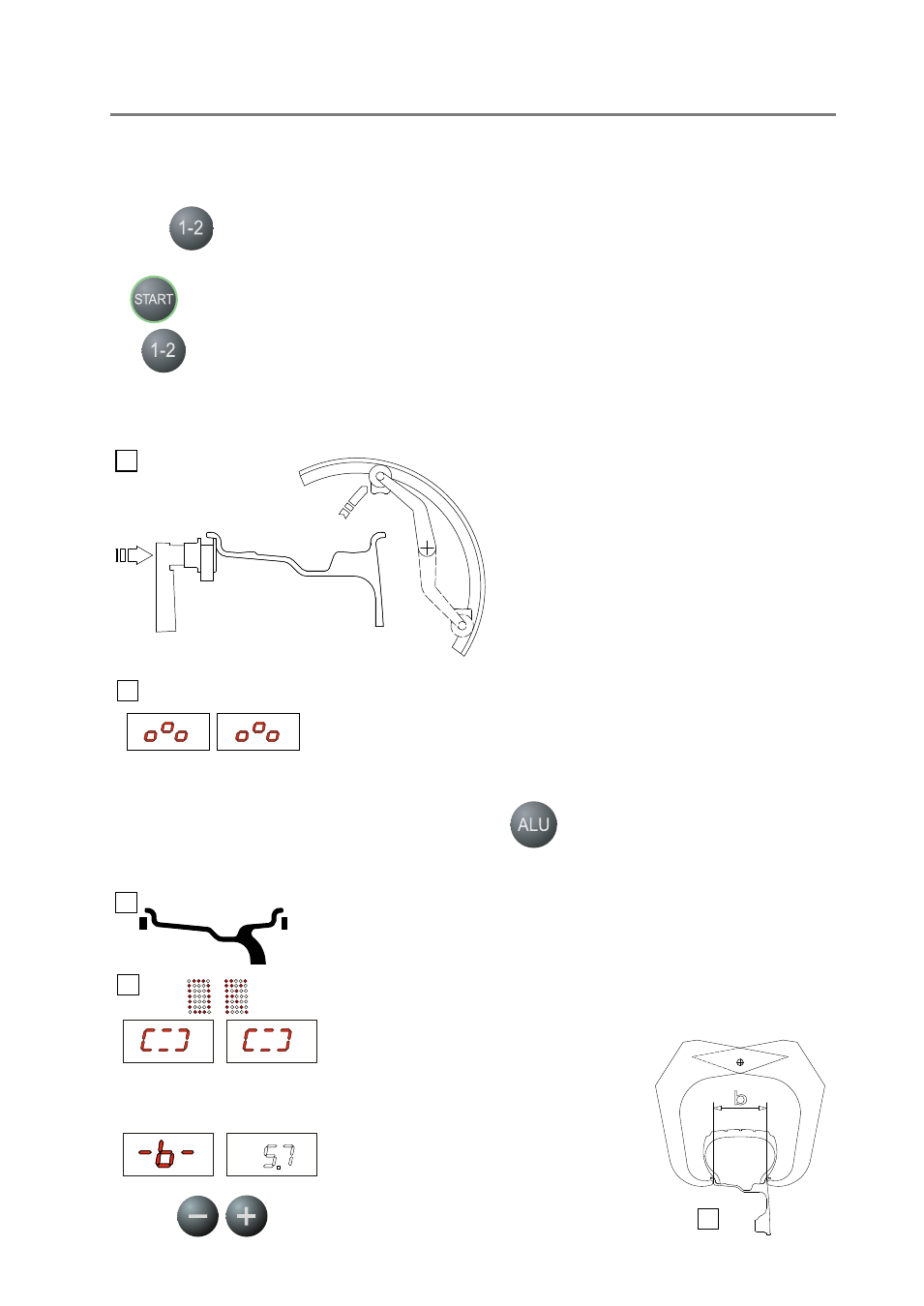

5.2 - Using the gauge installed on the machine

5.3 - Automatic setting of wheel dimensions

The machine automatically detects the correct balancing program for steel and aluminium rims (ALUS).

The counterweight position proposed may be changed using the

button.

a) DYNAMIC balancing of steel or light alloy rims with application of clip-on weights on the edges of the rim.

For clamp weights, use the gauge in the top position

A.

For adhesive weights, use the gauge as preferred in

top position A or bottom position B.

Note: Always use the round part of the striker

plate resting on the rim.

Indication of gauge in movement.

Pull out the gauge as far as the inner edge of the rim such as indicated in fig. 8.

Hold it in this position until the symbol shown in Fig. 8c is displayed.

Indication of dimensions acquired

N.B.: When the beep signal is enabled (see section

CONTROL OF THE

FUNCTIONS MENU

), reaching of the dimensions

is accompanied by a “beep” .

Return the gauge to rest position.

The machine has automatically detected

DISTANCE + DIAMETER and goes to MANUAL

WIDTH SETTING.

- The nominal width is normally stamped

on the rim; if not, proceed to measure

dimension “-b-” with the calibre gauge

(supplied as standard).