CEMB USA C75_2-L (A) User Manual

Page 9

I 0463 - 9

5

6

GB

4 - Controls and components

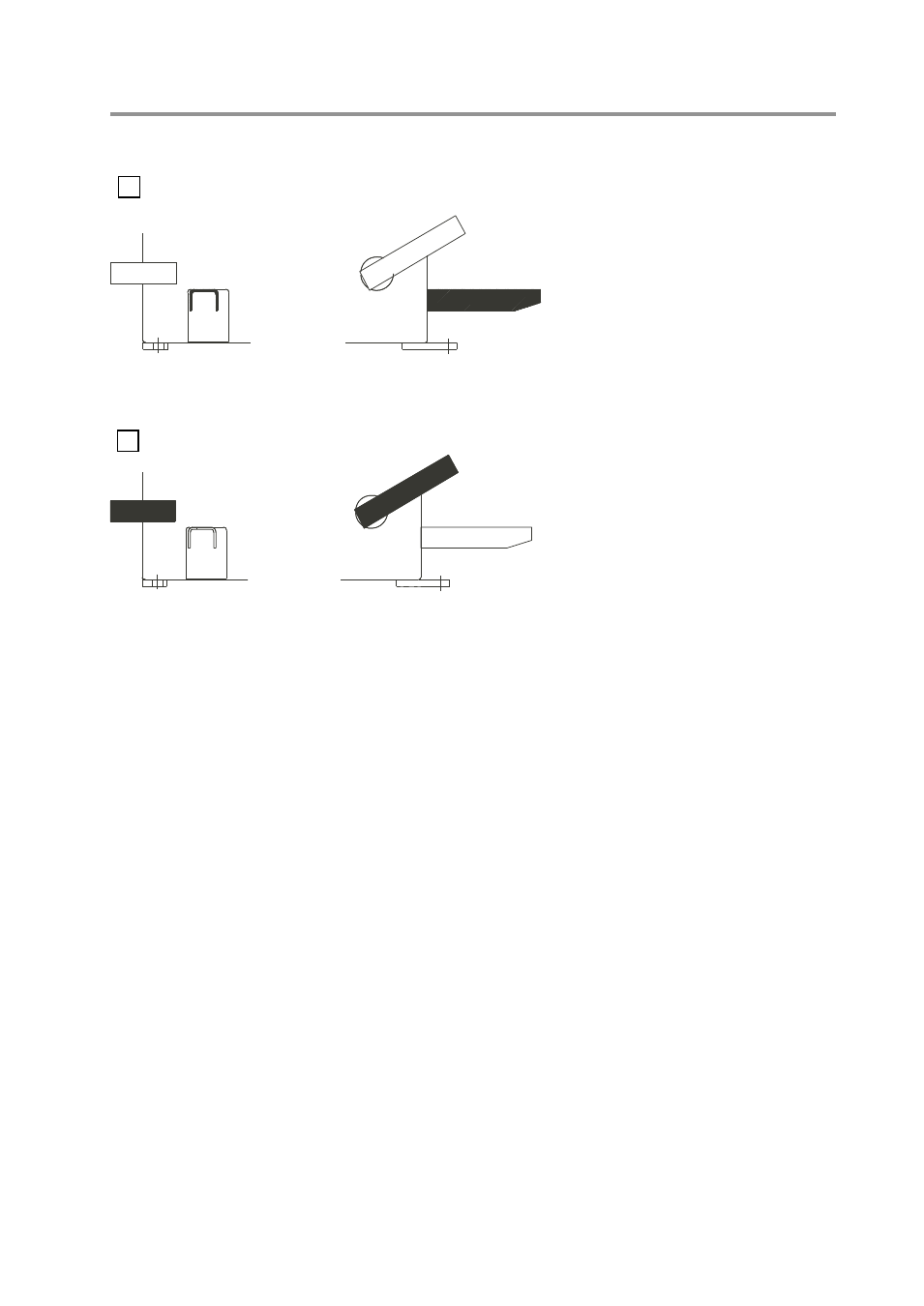

4.1 - Brake pedal

This pedal allows the operator to hold the

wheel when fitting the counterweights.

It

must not be actuated during the mea-

suring cycle.

4.2 - Pneumatic locking pedal (SE Version)

This pedal allows releasing the device

fastening the wheel on the adapter.

Do not

actuate this pedal during the machine

cycle and/or when adapters other than the

standard cone adapter are mounted.

The pedal has two stable positions:

top, wheel unclamped; bottom, wheel

clamped.

4.3 - Automatic distance and diameter gauge

This gauge allows measurement of the distance of the wheel from the machine and the wheel diameter at the point of

application of the counterweight. It also allows correct positioning of the counterweights on the inside rim by using the

specific function (see

INDICATION OF EXACT CORRECTION WEIGHT POSITION

) which allows reading, on the monitor,

the position used for the measurement within the rim (For calibration, see the corresponding section).

The gauge can only be used with the counterweight pincers mounted.

4.4 - Automatic width gauge (optional)

Width gauging is through a SONAR device which measures the distance of the wheel without mechanical contact,

merely by closing the guard and each time a valid measurement has been made with gauge

AUTOMATIC DISTANCE

AND DIAMETER GAUGE

.

4.5 - Automatic wheel positioning

At the end of the spin, the wheel is positioned according to the unbalance on the outside or else according to the static

unbalance (when selected).

Accuracy is ± 20 degrees.

4.6 - Clock control

The wheel balancer is provided with a clock having a back-up of about one month with the machine switched off. If the

machine remains off for a long period, at the first switch on, check the date and time (see

CLOCK SET-UP

), adjusting

them if necessary.

4.7 - Printer (option)

Used to print useful information for the vehicle, residual imbalance and eccentricity for the balanced tyre.