CEMB USA C88 (A) User Manual

Page 21

I 0607 - 21

GB

SOLUTION:

Rotate the tyre on the rim by 180°

RESULT:

no improvement is obtained

5.6.1 - Presetting of tolerance on the machine

There is no general rule concerning acceptability of an eccentricity value . As a fi rst approximation we consider it

correct to use a threshold of 1 to 1.5 mm / 0,0375” ÷ 0,056”. The E/ECE/324 standard prescribes 1.5 mm / 0,056” as

max. eccentricity of a rebuilt tyre.

5.6.2 - Value of static unbalance, correlated with eccentricity

Clear indication is given in the Measurement screen of both the value and position of the static unbalance as well

as the eccentricity. In fact, it is interesting to check the correlations of the two values, above all of the two positions.

When the two positions have a similar angle (± 30° one from the other), there is a clear sign that an eccentricity is

present which can be compensated by matching.

5.6.3 - Value of unbalance corresponding to eccentricity

For user’s reference, the centrifugal force is calculated corresponding to a certain speed, compared to the force

generated by the eccentricity present on the tyre (calculated with an approximate average elastic constant).

►

►

►

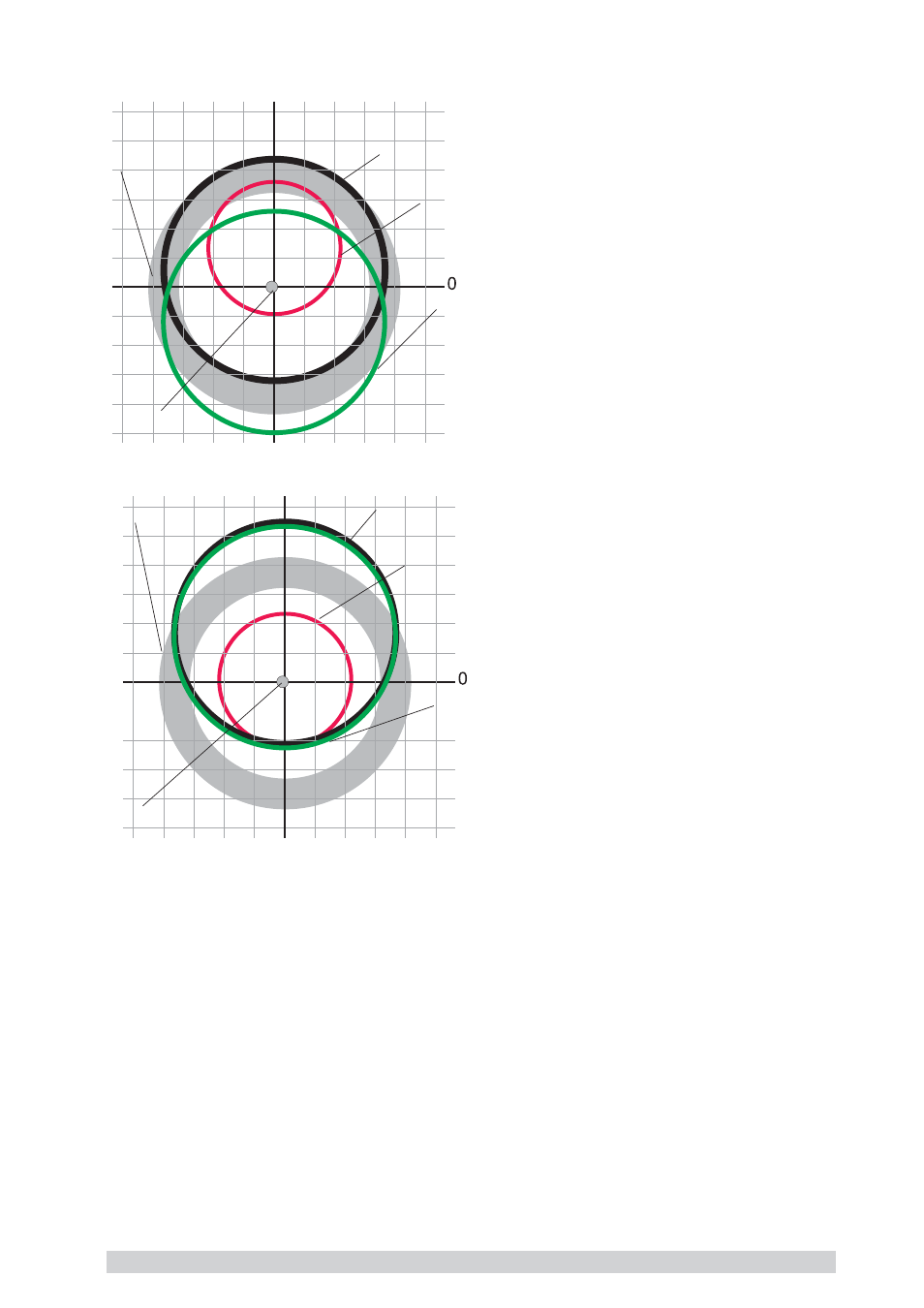

Example 2

Rim + 0.8 mm / 0,030”

Tyre - 0.6 mm / 0,0225”

Wheel + 0.3 mm / 0,010”

Eccentricity of the single items has

been compensated.

The wheel is acceptable.

Example 3

Rim 0 mm

Tyre + 1.2 mm / 0,045”

Wheel + 1,2 mm / 0,045”

Eccentricity of the wheel cannot be

compensated by the rotation because

the rim is perfect!

wheel

rim

tyre

rotation axle

Ideal wheel

wheel

rim

tyre

rotation axle

Ideal wheel