CEMB USA C211 (C) User Manual

Page 5

I 0147 -

4

I 0147 -

5

3

A

B

GB

GB

3 - Commissioning

3.1 - Electrical power supply

WARNING: The electrical connection must be made by specialized personnel. Connection to the single

phase mains must be made between phase and neutral, and never, under any circumstances,

between phase and earth (ground). Efficient earthing (grounding) is essential. The Manufacturer

declines all responsibility and warranty in the event of incorrect connection.

Before connecting the machine to the mains through relative cable, check that the mains voltage matches the one

shown on the nameplate at the back of the balancing machine. Rating of the electrical connection should be on the

basis of the machine electrical power consumption (see nameplate).

- The machine mains supply cable should be fitted with a plug conforming to current regulations.

- It is recommended to provide the machine with its own electrical connection through a slow acting safety switch

rated at 4 A (230 V) or 10 A (115 V).

- When connection is made directly to the main control panel without using any plug, it is advisable to padlock the

main switch of the balancing machine in order to limit its use to authorized personnel only.

3.2 - Pneumatic connection

Connect the machine to the compressed air main. Do not use the machine if there is no pressure. Max. permissible

inlet pressure is 10 kg/cm

2

(approx. 10 bar or 145 PSI or 1Mpa). Make the connection to the pressure limiting unit at

the back of balancing machine. The pneumatic circuit is designed to give the Lift considerable “flexibility” of move-

ment in any position of its stroke; thanks to this the wheel position can be adjusted according to requirements with

minimum manual effort.

3.2.1 -

Pressure adjustment for spin and braking device

Use relative knob on the compressed air preparation unit to adjust the pressure. Average pressure setting is 4 to 5

kg/cm2 (approx. 4 to 5 BAR or 60 to 75 PSI or 0.4 to 0.5MPa).

N.B. An excessively high pressure could led to rapid wear on the rubber on the driving pulley.

Lubrication is essential for correct machine operation. Oil flow rate is adjustable via relative screw on the oil tank.

Tighten or loosen the screw until a drop of oil falls per every 10 consecutive spins.

CAUTION! Only use mineral oil with average viscosity (30 cST at 40°C - WAIRSOL, LXOL grade).

4 - Assembly

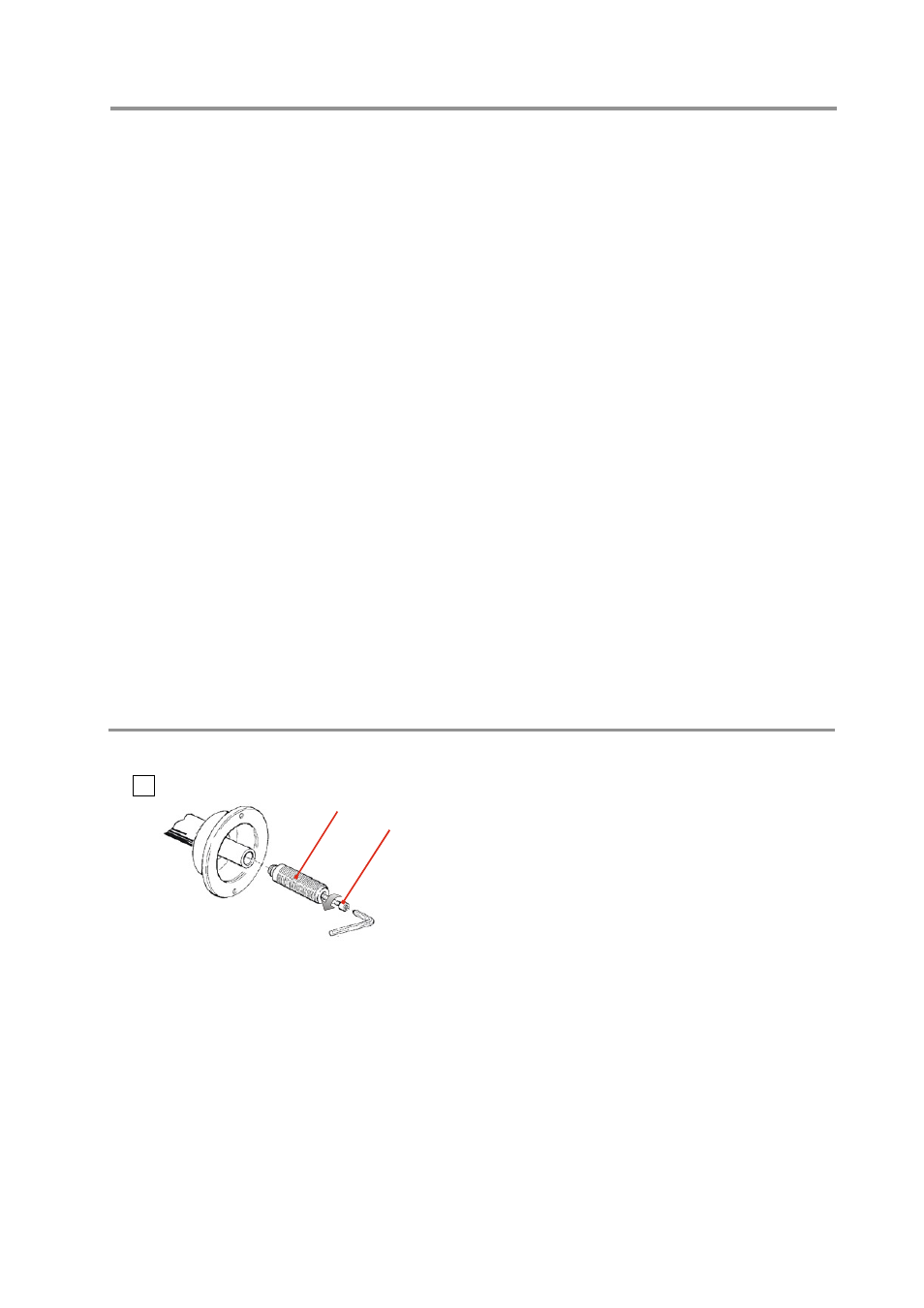

4.1 - Adapter mounting

The wheel balancer is supplied complete with cone

type adapter for fastening wheels with central bore.

Other optional adapters can be mounted:

a) Remove threaded end piece A after backing off

screw

b) Mount the new adapter (see enclosed

brochures).

4.2 - Wheel mounting

The wheels should be fastened with one of the numerous adapters builded by The Manufacturer (see enclosed

brochures).

N.B.: Incorrect centering inevitably causes unbalance.

4.3 - Guard mounting and adjustment (option)

a) Fasten the components to the base as illustrated in specifical exploded drawing.

b) The positions of these guards can be adjusted using the special screws accessed from inside the main support.

c) Check that the microswitch is held down when the guard is closed.

d) Adjust the angular position of microswitch control.