Planning data, Electrical data – Schreiber Chillers 2203AC - 3-Stage Chiller User Manual

Page 10

PLANNING DATA

Chiller Installation

The chiller should be installed on a level surface or sub base. Vibration isolation

is not provided by Schreiber Engineering and should be installed per requirements of local codes.

The bolt pattern diagram contains the corner weights for chiller and condenser mounted together

(AC configuration). (SEE DRAWING ON THE BACK FOR DETAIL ON CLEARANCE AND

WEIGHT INFORMATION)

The chiller should be installed in an area free from dirt and debris than can clog the condenser

coil. It should also not be installed near any places where hot exhaust air would enter the

condenser.

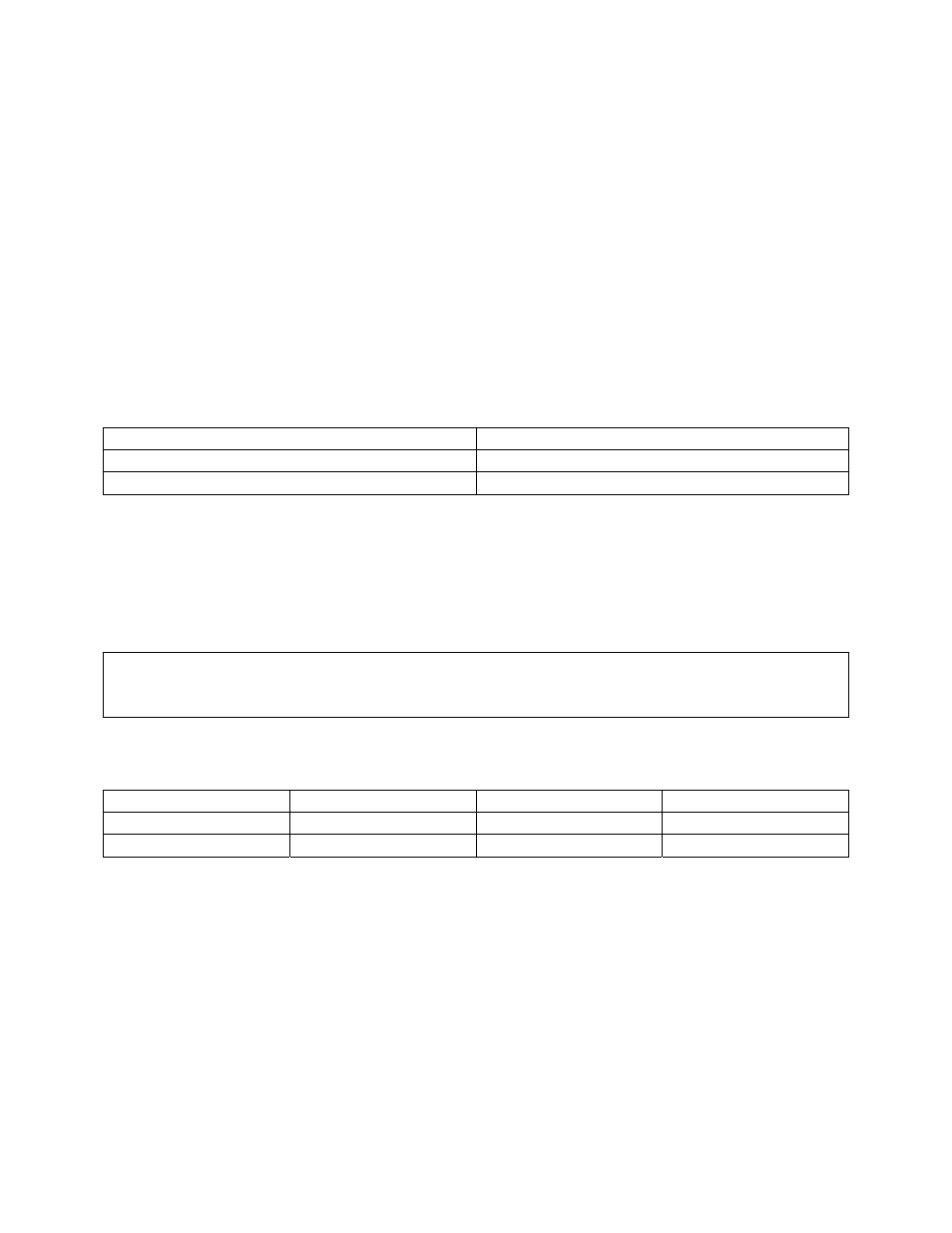

WEIGHT

CHILLER (DRY WEIGHT)

3500 lbs

HVAC Requirements: not applicable for 3- stages chiller

If the condenser is installed indoors, adequate fresh air must be brought into the space and

exhausted. If the chiller section only is installed indoors, a small amount of heat is added to the

space and should be accounted for in HVAC load calculations.

HEAT REJECTION (BTU/HR) AIRFLOW (CFM)

CHILLER 3,750 N/A

CONDENSER 375,000 23,750

Electrical Data

MODEL

FLA

MIN SUPPLY

MAX FUSE

2203AC-480/3 65 78 90

2503AC-480/3 70 85 100

Each chiller has one non-fused disconnect. The branch circuit for the chiller should be protected

by fuses no larger than listed in the above table. If more than one chiller is to be installed, each

chiller requires a dedicated, fused circuit.

REMOTE TERMINAL

The remote terminal can be installed in any indoor location. It is connected to the chiller via a 6-

conductor data cable. It is terminated with phone jack style connectors. The remote terminal is

wall mounted. Refer