Piping installation – Schreiber Chillers 15medWC User Manual

Page 9

NETWORK REQURIMENT:

Some chillers may be shipped with optional modem or TCP/IP connection. A phone line and

number is required for the modem, and a permanent network connection is required for TCP/IP.

Your network’s router will have to be configured so that the IP address for the chiller is exposed

outside of the facility’s LAN.

Piping Installation:

Two chilled water loops are required for each chiller, one for the Cryo-compressor and one for

the water-cooled heat exchangers.

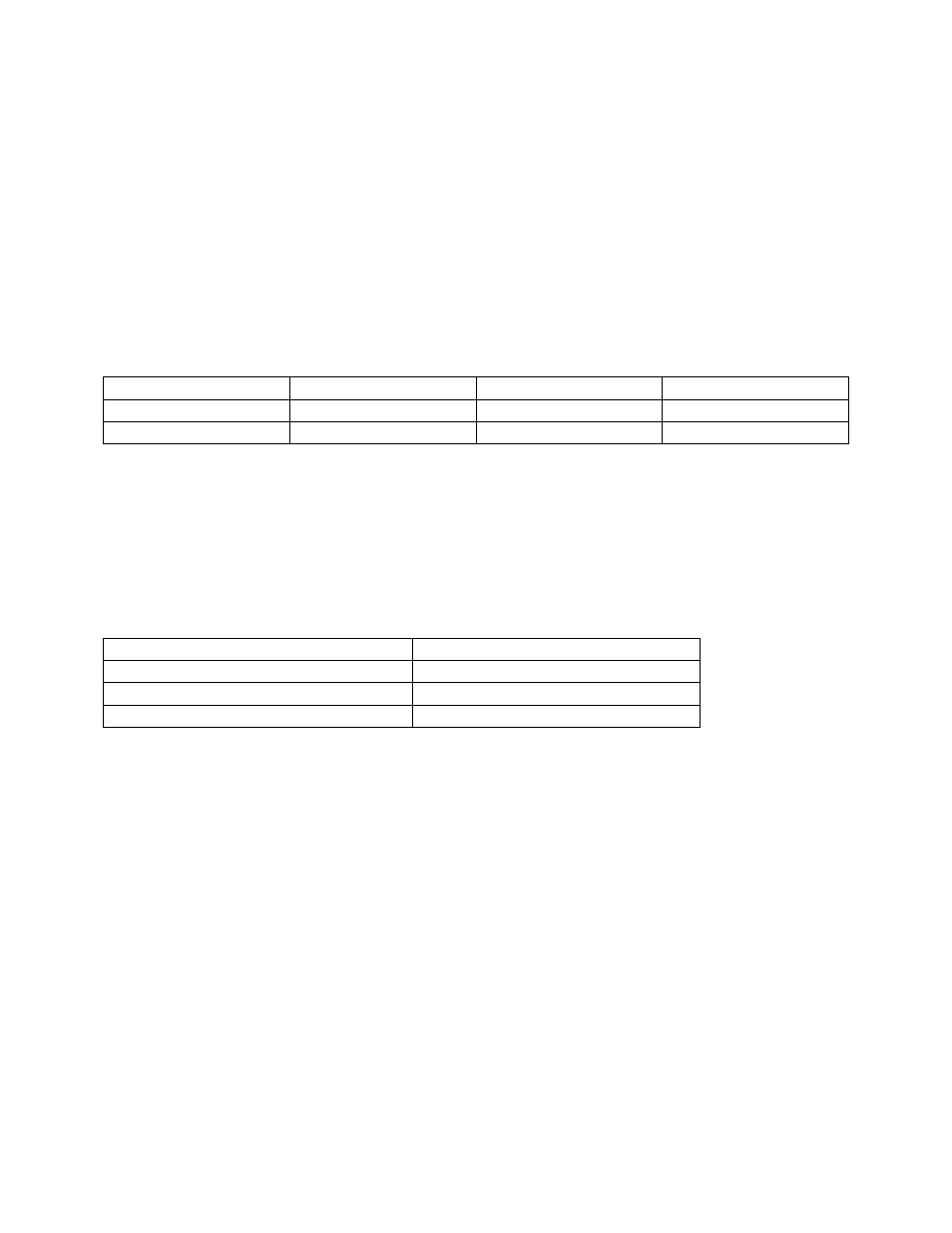

CHILLER

CON.

DESIGN

FLOW

MIN. PIPE SIZE

CRYO-COMP

½” FPT

1.5 usgpm

½”

HEAT XCHANGER

1” FPT

16 usgpm

1”

*Based on a total piping length of 300’ per loop.

Only use copper or PVC (schedule 80) piping. All piping should be insulated to prevent

condensation and to minimize heat gain from the ambient air. A maximum of 30% by volume of

Ethylene Glycol can be added to the system. The glycol should be added directly to the reservoir

through the fill port. To get the proper percentage, the reservoir volume should be added to the

piping volume to get the total amount of fluid in the system. Since both chilled water loops pull

water out of the same reservoir, both loop volumes should be calculated.

PIPE SIZE (BASED ON COPPER) VOLUME

(GAL/100FT)

½” 1.2

¾” 2.5

1” 4.3

A pressurized water supply and hose should be provided at the site for filling the chilled water

reservoir. Automatic fill systems are not used because of unintended glycol dilution.

Since the reservoir is vented to atmosphere, expansion tanks are not required in the piping

system

A float in the reservoir will send an alarm to check the water level in the reservoir, without

shutting the chiller down.