Quality vakuum products, inc, Basic veneering principles, Over – Q.V.P. VAKUUM BAGS WITHOUT BASEBOARDS User Manual

Page 3

Quality VAKuum Products, Inc.

Or visit our site at

www.qualityvak.com

CALL 1-800-547-5484 TODAY!

OVER

BASIC VENEERING

PRINCIPLES

5/4/98 - Basic Veneering Principles.cdr

FLAT SURFACES

1. Start with cutting the substrate to the finished size.

Good substrate materials are;

MDF, particle board or

plywood. If solid wood is to be used, a cross ply must be

applied and allowed to dry unless the panel is less than

1/4" thick.

2. Prepare a caul by rounding all edge that will be touched

by the VAK bag. The caul should be approximately 3/4"

larger than the substrate and made from 1/2 to 1" thick

melamine coated particle board. Any flat material can be

used, however, the coated stock has several advantages.

First, the coating makes it non-porous. With porous

material, the vacuum pulls the air from the pores over a

period of time, this has the effect of breaking the vacuum

prematurely. This causes the VAK Matic Controller to

cycle on and off more often. A coated caul can also be

lightly waxed, this helps keep the excess glue from

sticking.

3. The veneer should be matched and placed face down on

the caul. It should be about 1/4" larger than the substrate

so that it overhangs the substrate by at least 1/8" on all

sides. Tape the veneer to the substrate, however, make

sure that the tape will not touch the substrate when it is

placed on top of the veneer. You do not want to trap tape

under the veneer.

4. Glue one face of the substrate. Many use the regular

yellow glues unless the workpiece is going in a special

area where it sees some unusual conditions like excessive

heat (fireplace panels) or high moisture. Apply glue to the

top of the substrate and align the top caul, with its taped

veneer, on top of the substrate.

5. Tape the assembly together so it will not move when

placing it in the VAK Bag.

CURVED SURFACES

1. Build your mold with the knowledge that it will see almost

1 Ton/sq.ft of pressing force. A weak mold will get

crushed. This is also true of curved furniture. Veneering a

hollow round base can be a problem unless the inside is

structurally sound.

2. Make the mold convexed whenever possible and do not

totally close it in. Leave the bottom open or cut some slots

in the bottom so that air is not trapped inside.

3. Use the mold as the bottom caul and wax it as with a flat

caul. Tape the bottom veneer to the mold. Glue the

bending ply/substrate and place it over the veneer. The

number of bending plys glued at one time depends on the

size, thickness and stiffness of the ply. Glue several plys if

they are flexible enough to be bent in the bag. In some

cases, you will help the bag by pushing down on the

flexible top caul, as the bag is being evacuated. Once

evacuated, the bag will hold everything down.

4. Lay the top veneer on top of the glued substrate. Tape

the top caul to the assembly only at the points where it

meets the bottom assembly. If you tape it all the way

around, like with the flat panel, the inner plys may not slide

into their proper radius without causing a misalignment

problem.

5. Place a piece of plastic sheet over the top veneer and

tape in place. Place the top caul (bending ply) in position

and tape in place. Slide the completed assembly into the

bag. Start the VAK pump and hold the assembly down

while the reaches the desired vacuum level.

Notes:

A. Always try a dry run to make sure all the pieces fit to

gather and fit in the bag without problems. Go as far as to

pull the maximum vacuum with a new piece or shape.

B. Know your time limits for assembly, glue, and bag

evacuation so that you don't get caught short.

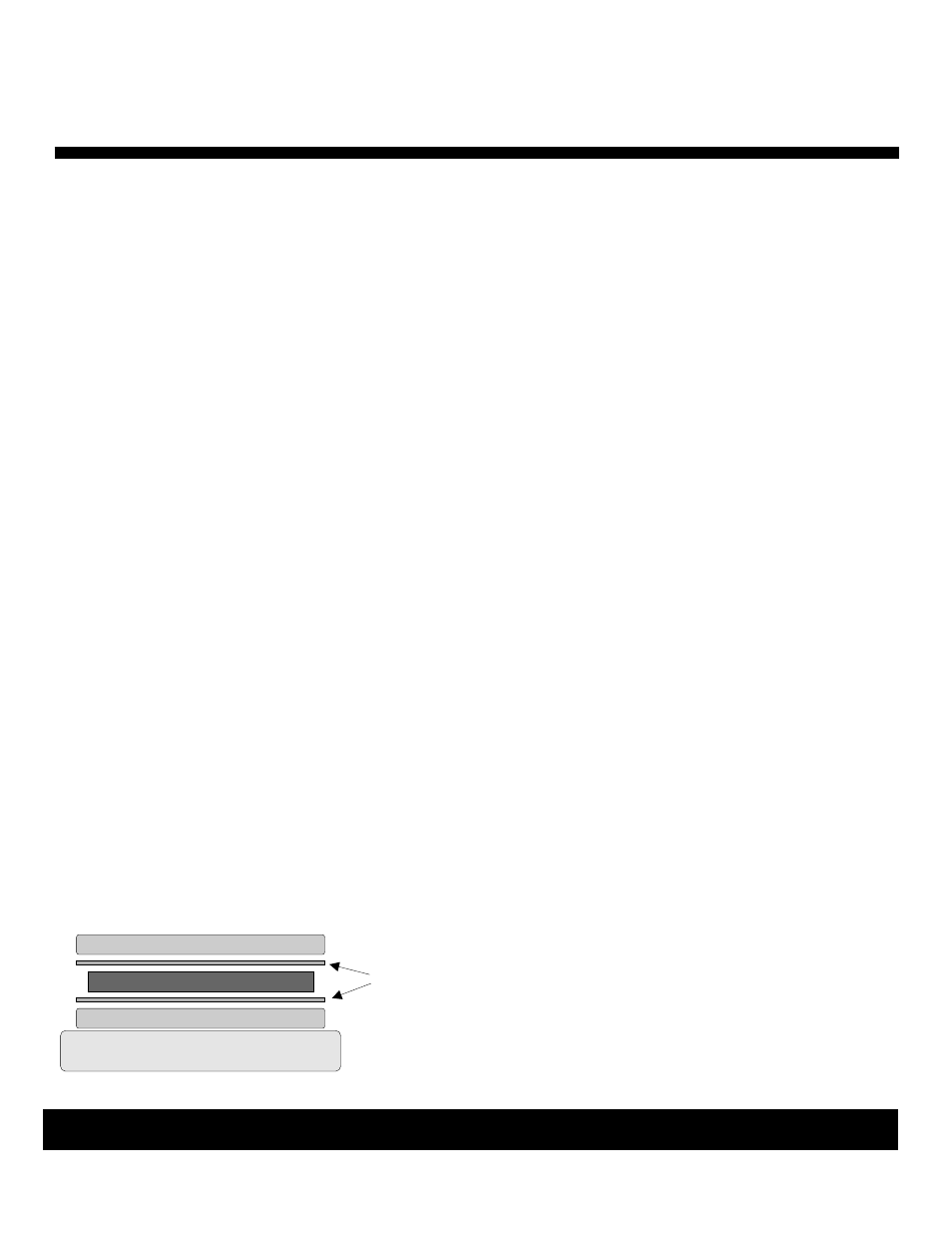

Base Board

Bottom Caul

Substrate

Top Caul

Veneer

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681