Q.V.P. VAKUUM BAG User Manual

Quality vakuum products, inc, Instructions for assembling the vakuum bag, Drawing a

Quality VAKuum Products, Inc.

Or visit our site at

www.qualityvak.com

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

CALL 1-800-547-5484 TODAY!

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM BAG

05/18/05 - Bag Instructions.cdr REV5

BASEBOARD

The purpose of the baseboard (BB) is to provide a base for

the workpiece to lie on. It should be a minimum of 6“

shorter and 4” narrower than the bag dimensions. This will

allow for materials to be put inside the bag without

excessive stretching. The BB should be made with any

ridge material that is flat and a minimum of 3/4” thick. It’s

also best to have a non-porous material that will not absorb

glue or outgas when under vacuum. Melimine coated

particle board is a good material for the BB.

The top of the BB needs saw kerfs or channels cut every 6 -

8“ in the length and width. These channels permit air to be

evacuated when the top of the bag is flat against the BB.

Round all edges and corners and remove any splinters. If

you use a narrow blade saw (.030”), you can use the

basebaord as the bottom caul. Always test to make sure

that the veneer does not show impressions from the kerfs.

This can save time and money from not having to make

different size cauls.

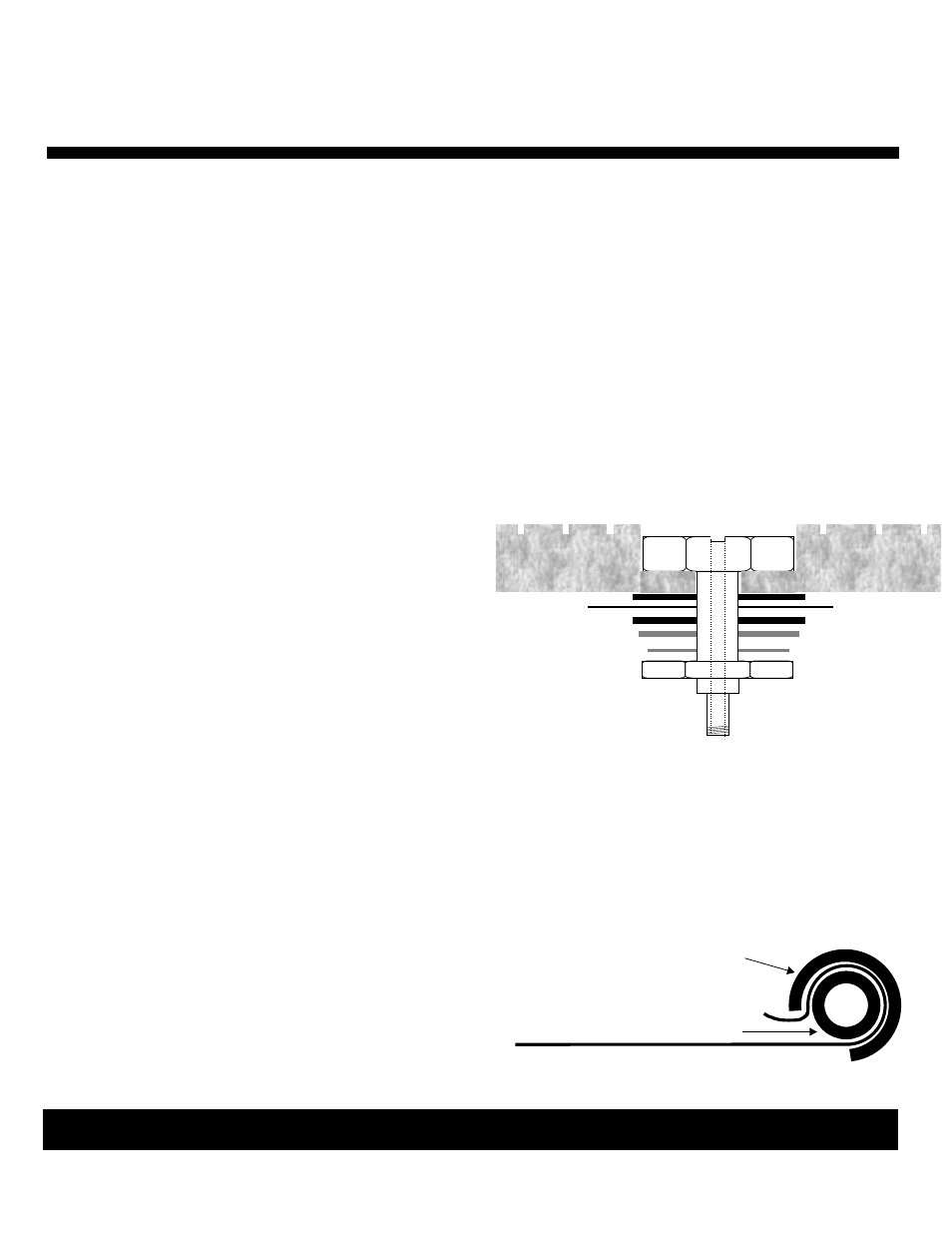

Next, a hole is needed for the VCA(6) or vacuum connector

assembly. At an intersection of two channels that is at

least 6“ from the edge of the bag, drill a 1-1/8” dia. hole

5/16” deep (1” dia. For VCA) Then drill a 3/4” dia. hole

through the BB (5/8” for the VCA). Make sure the exit hole

is clean and splinter free. Remove the nut, two metal

washers and the rubber washers from the VCA. Push the

brass piece through the BB so that the bolt head is in the

recessed hole (should be slightly below the top of the BB).

Place one of the rubber washers over the stem and snug it

up to the bottom of the BB. See drawing A. Slide the BB

into the bag, the rubber washer holds the brass stem in

place.

Position the BB in the bag and cut an X, in the bag, (use a

sharp knife, especially on poly bags) over the hole in the

barb and then push the bag down to the rubber washer.

Trim the excess bag material, do not over trim as it should

be a snug fit.

Place the other rubber washer over the stem, then the

large metal washer followed by the lock washer and the

nut. With one hand hold the bag to prevent it from twisting

and sung up the nut. Do not over tighten.

Turn the bag/BB over and attach the pump per the

assembly instructions. It is suggested that the bag be

placed on cardboard or a mat to prevent it from picking up

splinters.

Drawing A

RUBBER

WASHERS

BAG

METAL

WASHERS

VCA6

CLOSING THE BAG

Place the plastic rod about 2“ from the open end of the bag.

Fold the open end over the rod once, leaving about 1”

overlap. Snap the C-Closure over the bag and rod.

Sometime it will help to put spring-clamps on the closure to

keep it from opening when it’s under tension. This can

occur when there are large objects in the bag.

TESTING THE BAG

Power the pump, the vacuum gauge should read between

23 and 25“Hg (inches of mercury) when the automatic units

reach’s vacuum level and shuts off. The unit will cycle on

and off as it needs vacuum. If the on/off cycles are short

(less than 2 minutes) and do not get longer with time, then

you have a leak or you did not cover the vacuum hole.

05/17/05R3

If your workpiece does not cover the vacuum hole, place a

piece of stock (3“x3”x1/2” round all edges) over the vacuum

hole. This will prevent the bag from being sucked into the

hole and blocking the air flow before the bag is totally

evacuated.

Bag

Rod

C-Closure

Baseboard

Nut

L