Ω ω ω ω, Fig.3 types c, fc and f, s clutches, Shrink disc couplings – DE-STA-CO Output Overload Clutches Type F, FC, S, C, D, FC-SD, C-SD User Manual

Page 5

ASSEMBLY INSTRUCTIONS

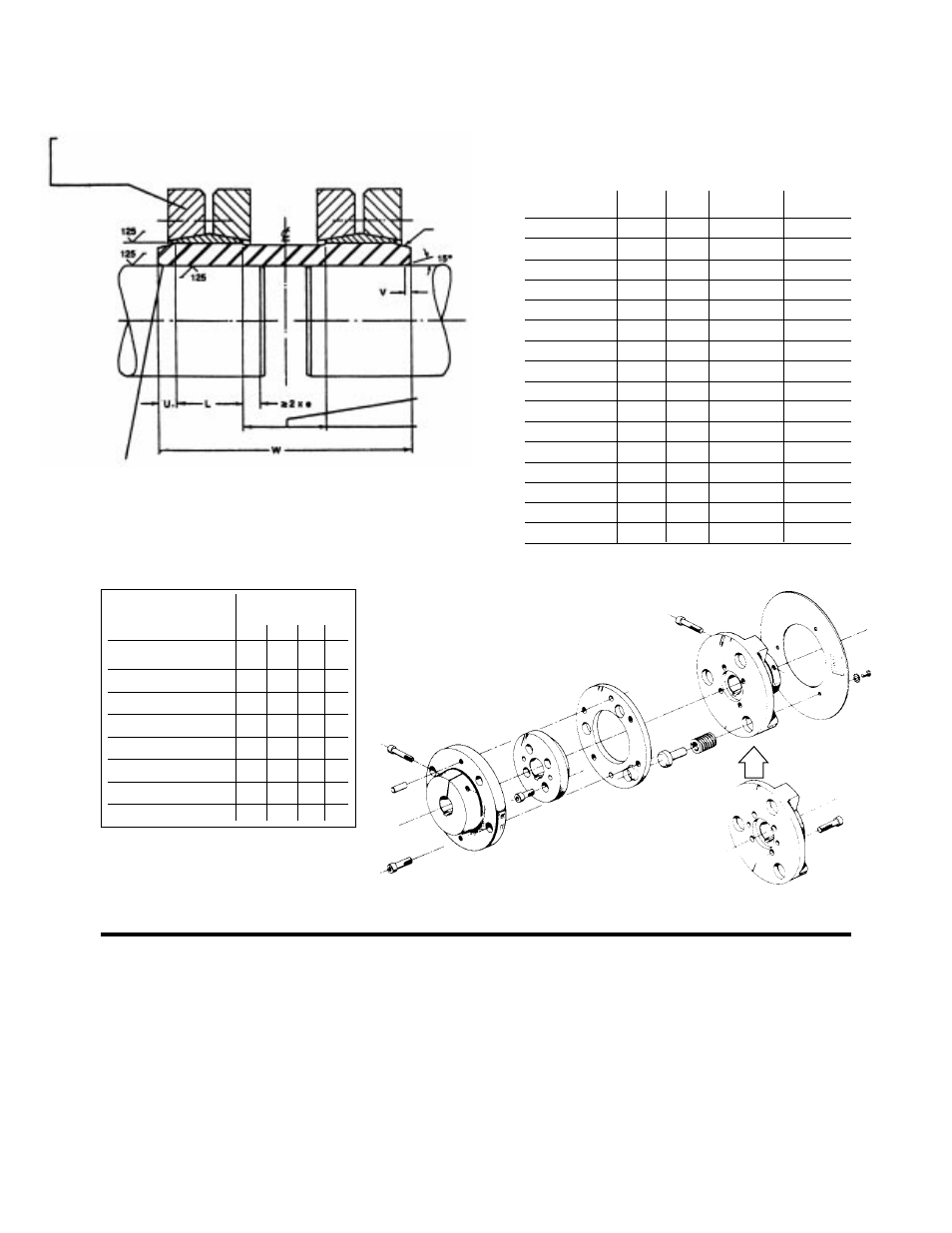

See Fig. 3 for required assemblies

Important: To obtain maximum accuracy in

positioning the DRIVEN MEMBER, the INDEX

DRIVE "CAM SHAFT" must be in the EXACT

CENTER OF DWELL position. See CAMCO

drawing applicable to the Index Drive Model.

1. Insert PLUNGERS ❼ into SPRlNGS

Ω

and

install the assemblies in the BODY pock-

ets. Test for free movement of the plungers.

Lightly lubricate the body pockets, springs

INSTALLATION INSTRUCTIONS TYPES C AND FC CLUTCH COUPLINGS

5

∫

OR

❼

S, C BODY

∏

Ω

F, FC BODY

HUB (NOT USED ON F, S

)

∑

REQUIRED

ASSEMBLIES

CLUTCH TYPE

(FIG. 3)

C

FC

F

S

HUB

➊ ➊

FLANGE PLATE

∑ ∑ ∑ ∑

DRIVE PLATE

∏ ∏ ∏ ∏

BODY (S, C)

π

π

DETECTOR PLATE

∫

∫ ∫ ∫

BODY (F, FC)

❻ ❻

PLUNGERS

❼ ❼ ❼ ❼

SPRINGS

Ω Ω Ω Ω

SPRING

DOWEL PIN

π

DETECTOR PLATE

❻

➊

FLANGE PLATE FOR F & S (ONLY)

OR

RETAINER RING FOR C & FC (ONLY)

MOUNTING SCREWS

Fig.3

TYPES C, FC AND F, S

CLUTCHES

PLUNGER

DRIVE PLATE

SHRINK DISC

U

V

SERIES 01

SERIES 03

SIZE

140

5/8

1/8

8.00

9.00

145 thru 155

5/8

1/8

8.38

9.50

160 thru 175

7/8

1/8

9.00

10.50

180 thru 200

7/8

3/16

11.00

12.63

220

7/8

3/16

12.25

14.38

240

1

3/16

13.25

15.38

260

1

3/16

14.00

16.63

280

1-1/4

1/4

15.50

18.25

300

1-1/4

1/4

16.25

18.50

320

1-1/4

1/4

16.25

19.00

340

1-1/2

1/4

17.75

21.00

350 & 360

1-1/2

1/4

18.25

21.25

380 & 390

1-1/2

5/16

18.75

22.25

420

1-3/4

5/16

21.00

24.75

440 & 460

1-3/4

3/8

22.25

26.25

480 & 500

1-3/4

3/8

23.75

28.25

SHRINK DISC COUPLINGS

IFOR RIGID SHAFT CONNECTIONS- TRANSMIT TORQUES &

BENDING MOMENTS- PERMIT AXIAL & ANGULAR TIMING

SHRINK DISC (PREFERABLY USE UNITS WITH INTEGRATED HUB STOP) REFER

TO SHRINK DISC SPECIFICATION TABLE FOR SELECTION OF SHRINK DISC TO

MEET YOUR TORQUE & SHAFT SIZE REQUIREMENTS. CONSULT WITH US IF A

BENDING MOMENT HIGHER THAN 25% OF RATED TORQUE HAS TO BE

TRANSMITTED.

CHAMFER

≥

15˚

OPTIONAL RECESS

ON SLEEVE O.D.

ONLY IF SHRINK

DISCS WITH

INTEGRATED HUB

STOPS ARE USED

COUPLING SLEEVE CAN BE SUPPLIED BY BIKON CORP. USE

MATERIAL WITH A YEILD POINT OF AT LEAST 36000 PSI FOR LIGHT

DUTY APPLICATIONS, BUT AISE 1045 (OR BETTER) FOR MEDIUM DUTY

APPLICATIONS.

SEE SHRINK DISC SPECIFICATION TABLE FOR DIMENSIONS "L" & 'e"

RECOMMENDED SLEEVE DIMENSIONS FOR

SHRINK DISC COUPLINGS USING SERIES 01

& SERIES 03 SHRINK DISC SIZE 140 &

LARGER

and plungers with Mobilgrease 77 or

equivalent.

Caution: Do not overlubricate. Heavy

lubrication may prevent clutch disen-

gagement.

2. Install the FLANGE PLATE

∑

into the

DRIVE PLATE

∏

Lightly lubricate both

sides of the DRIVE PLATE and the ma-

chined face of the BODY with

Mobilgrease 77 or equivalent.