DE-STA-CO Output Overload Clutches Type F, FC, S, C, D, FC-SD, C-SD User Manual

Page 2

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

SAFETY INSTRUCTIONS

1. Read your Overload Clutch Installation-

Operation Instructions thoroughly before

operating the unit, for your safety and the

protection of your unit.

2. CAMCO Overload Clutches are designed to

protect the Index Drive only and will not

protect against bodily injury.

3. Double check to be sure the power is off

and cannot be turned on while working on

the equipment.

4. Use extreme caution with jammed or unbal-

anced loads, which when cleared may set

the machine in motion.

5. Keep all objects such as hands, clothing,

tools away from rotating or moving parts.

6. Use safety glasses or equivalent to protect

your eyes.

7. Dowel pins and mounting screws must not

protrude from the drive plate or driven

member as the clutch could become a solid

coupling.

8. High humidity, contaminants, or wash down

applications may cause rust within the

clutch, resulting in operational failure.

Lubricate every six months or more fre-

quently as the application requires.

9. The CAMCO clutch is not a "FAIL SAFE"

device and cannot be used on "overhauling"

or "holding" load applications.

The above list includes major safety points to

be observed, but should not be considered as

limiting in safety precautions to be followed.

OPERATING PRINCIPLE

CAMCO Overload Clutches are designed

for mounting on the output member of the

CAMCO Index Drive. An Index Drive is essen-

tially a variable ratio speed reducer. Each index

provides an incremental output to input torque

ratio, which may range from 1:1 in the center of

the motion, to as high as 1000:1 in the begin-

ning or end of the motion. As output torque

equals input torque times the ratio, a clutch

mounted on the input side provides no protec-

tion at the beginning or end of the motion.

CAMCO Overload Clutches provide zero

backlash, high rigidity, low inertia and are

specifically designed to be used in conjunction

with CAMCO Index Drives.

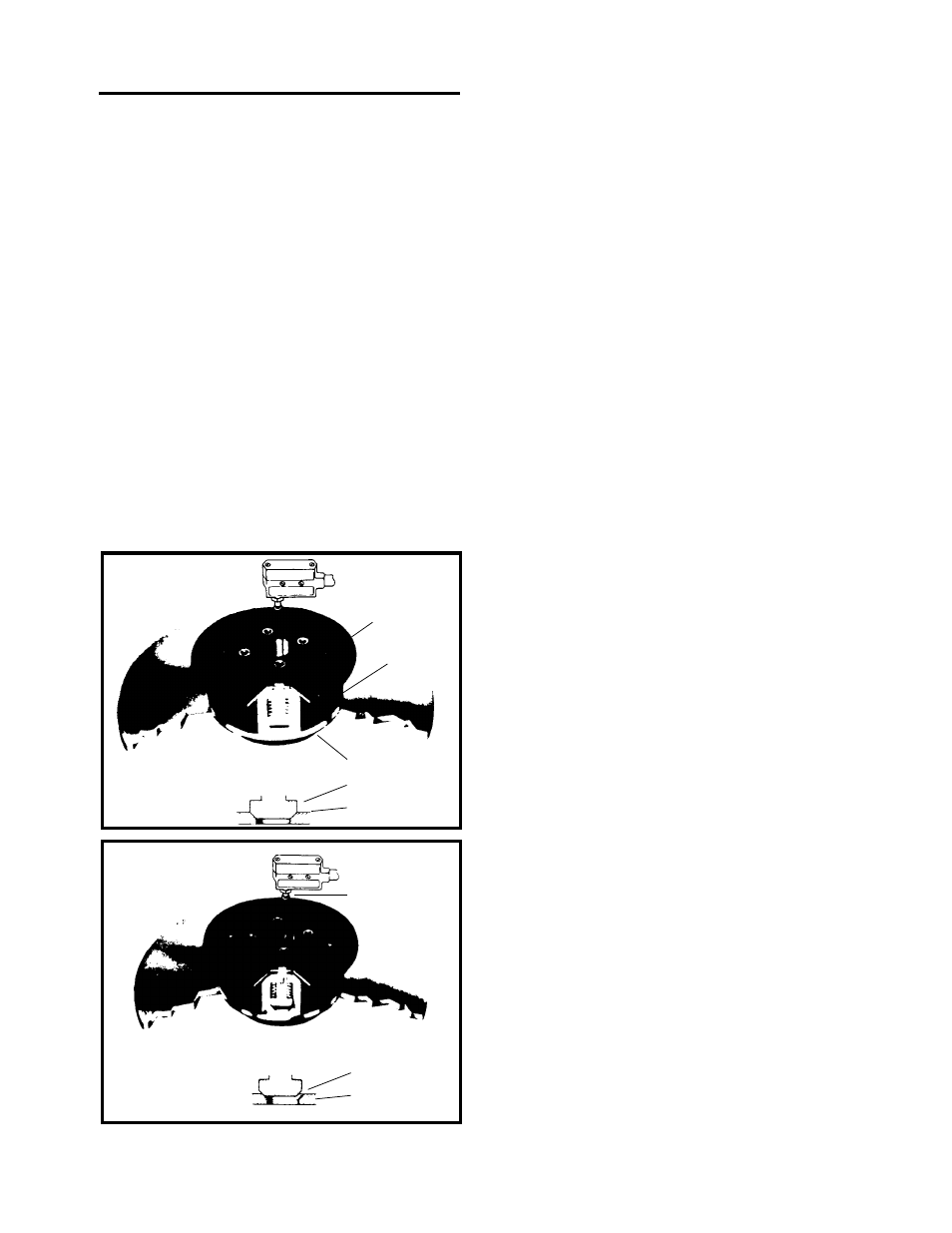

Power is transmitted from the Index Drive

through the body of the CAMCO Overload

Clutch. The body contains spring loaded

tapered plungers that engage in mating ta-

pered seats in the drive plate. (See Fig. 1.)

Torque settings are determined by the pressure

the calibrated springs "seat" the plungers.

When an overload occurs, which exceeds the

torque setting of the clutch, the breakaway

friction between the tapered plunger and the

tapered seat, forces the plungers outward from

their seats. The movement of the plungers

elevates the detector plate, actuating the limit

switch. (See Fig. 2.)

The CAMCO Overload Clutch always resets in

its original position, making it an excellent

choice on applications that must remain

registered or timed.

SWITCH NORMALLY

CLOSED

DETECTOR

PLATE

DRIVE PLATE

PLUNGER

DRIVE PLATE

DRIVING

POSITION,

TYPICAL FOR

EACH PLUNGER

BODY

SWITCH OPEN

WITHIN 0.008"

DEFLECTION OF

DETECTOR PLATE

PLUNGER

DRIVE PLATE

OVERLOAD POSITION,

DETECTOR PLATE IS

MOVED AXIALLY TOWARD

SWITCH BY TRAVEL OF

PLUNGERS

Fig.1

Fig.2

2