DE-STA-CO Output Overload Clutches Type F, FC, S, C, D, FC-SD, C-SD User Manual

Page 4

INSTALLATION AND REMOVAL

INSTRUCTIONS FOR SHRINK DISCS

Shrink Discs are supplied ready for installa-

tion. However, prior to tightening of locking

screws it is necessary to remove wooden

spacers located between outer collars, which

are used during shipment of Shrink Discs.

INSTALLATION

Important: Never tighten locking screws

before shaft installation, since inner ring of

Shrink Discs as well as hub can be perma-

nently contracted even at relatively low

tightening torques.

1 Clean hub O.D. and Shrink Disc bore and

lightly lubricate hub O.D. before assembly

of Shrink Disc on hub.

2 Carefully clean shaft and hub bore from

any lubricant prior to mounting hub onto

shaft. THIS STEP IS VERY IMPORTANT,

since it will greatly affect the torque

transmitting capability of a Shrink Disc

connection.

3 After checking correct position of Shrink

Disc and hub, handtighten 3 or 4 equally

spaced locking screws and make sure that

outer collars of Shrink Disc are in a parellel

position. Afterwards handtighten rest of

locking screws.

4 Use torque wrench and equally tighten all

screws one after another in a clock or

counterclockwise sequence by approx.

1/4 turns (even if initially some screws will

require a very low tightening torque) until

specified tightening torque MA is reached.

NOTE: To compensate for bolt setting

during installation, a 5% higher than

specified tightening torque is recom-

mended for final tightening round.

5 Reset torque wrench and make sure that

no screw will turn at specified tightening

torque M

A

.

NOTE: It is not necessary to check tightening

torque again after installation is completed or

equipment has been in operation.

REMOVAL

1. Loosen locking screws in several stages by

using approx. 1/2 turns, following either a

clock or counterclockwise sequence till Shrink

Disc can be moved on hub. DO NOT remove

locking screws completely.

2. Make sure any rust buildup in front of hub

is removed before hub is pulled from shaft.

RE-INSTALLATION OF SHRINK DISC

In relatively clean operating conditions, Shrink

Discs can be re-used without prior cleaning.

Severe conditions, however, require thorough

cleaning and re-lubrication with the following

or similar lubricants:

Tapers of inner rings and outer collar

bores: Molykote 3321 R-spray or

Molykote G RAPlD-spray or paste

Screwthreads and head contact area:

Multipurpose grease like Molykote BR-2

Damaged O-rinqs should be replaced.

4

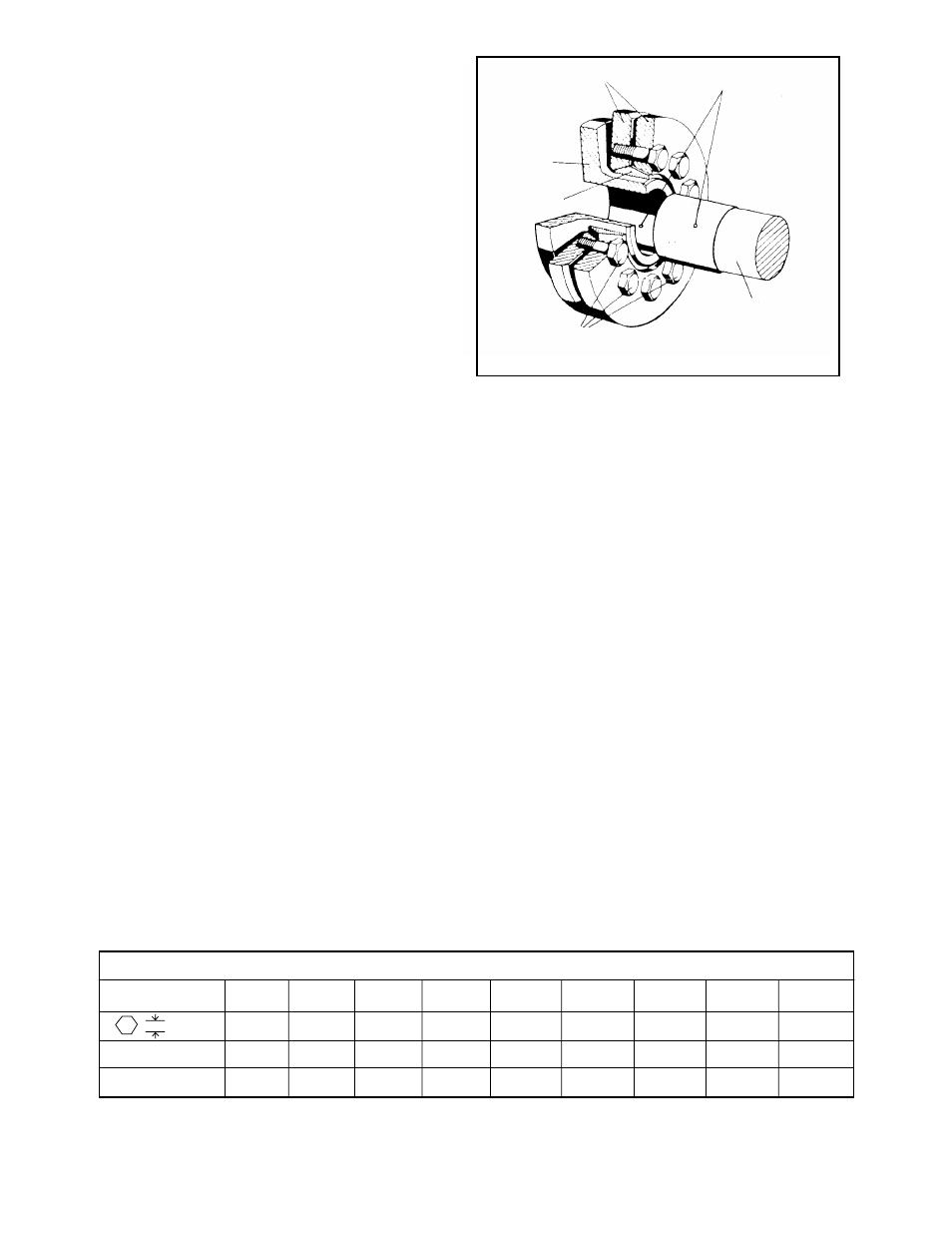

Inner Ring

Hub

Outer Collars

Metrix Hex Head Locking Screws

DIN 931, Grade 10.9

Shaft

IMPORTANT!

Carefully Clean

Shaft & Hub Bore

& Keep Free of Any

Lubricant

LOCKING SCREW-TIGHTENING TORQUES "M

A

"

screw size

M5

M6

M8

M10

M12

M16

M20

M24

M27

s mm

8

10

13

17

19

24

30

36

41

M

A

[Nm]

5

12

30

59

100

250

490

840

1250

M

A

[ft.-lbs]

3.6

8.7

22

44

74

185

362

620

922