Frequently asked questions cont’d, Troubleshooting, Dimensional data – BRAND Hydraulics EFC FLOW CONTROL User Manual

Page 2

04/14

FREQUENTLY ASKED QUESTIONS cont’d:

Q: Can flow be sent in reverse through valve.

A: Requires a special compensator spool to be accomplished. Valve number will begin with an EFCC. If you’re unsure of

your valve’s model number, please contact factory for assistance.

Q: How many amps are required to shift orifice spool to full flow?

A: 1 amp is required to fully shift orifice spool. 350mA is generally the amperage needed to see flow begin from the CF port.

Q: What kits are available for this valve?

A: There is a replacement seal kit available for this valve. (Part #: EFC-K) If valve is equipped with a relief, there also is a

relief kit available (Part #: EFCR-K)

TROUBLESHOOTING:

Problem: Valve chatters or has stability issues. Instability generally occurs when the valve sees an application that has

rapidly changing loads. (ie: Fan, Vibration, etc.) Because of these changing loads the compensator spool tries to compensate

rapidly. This causes the valve to become unstable, as well as begin to make noises, including a chatter.

Solution: Most instability issues can be solved by using a different compensator spool or spring. A replacement spool

designed for load changing applications can be ordered. (Part #: XDC609)

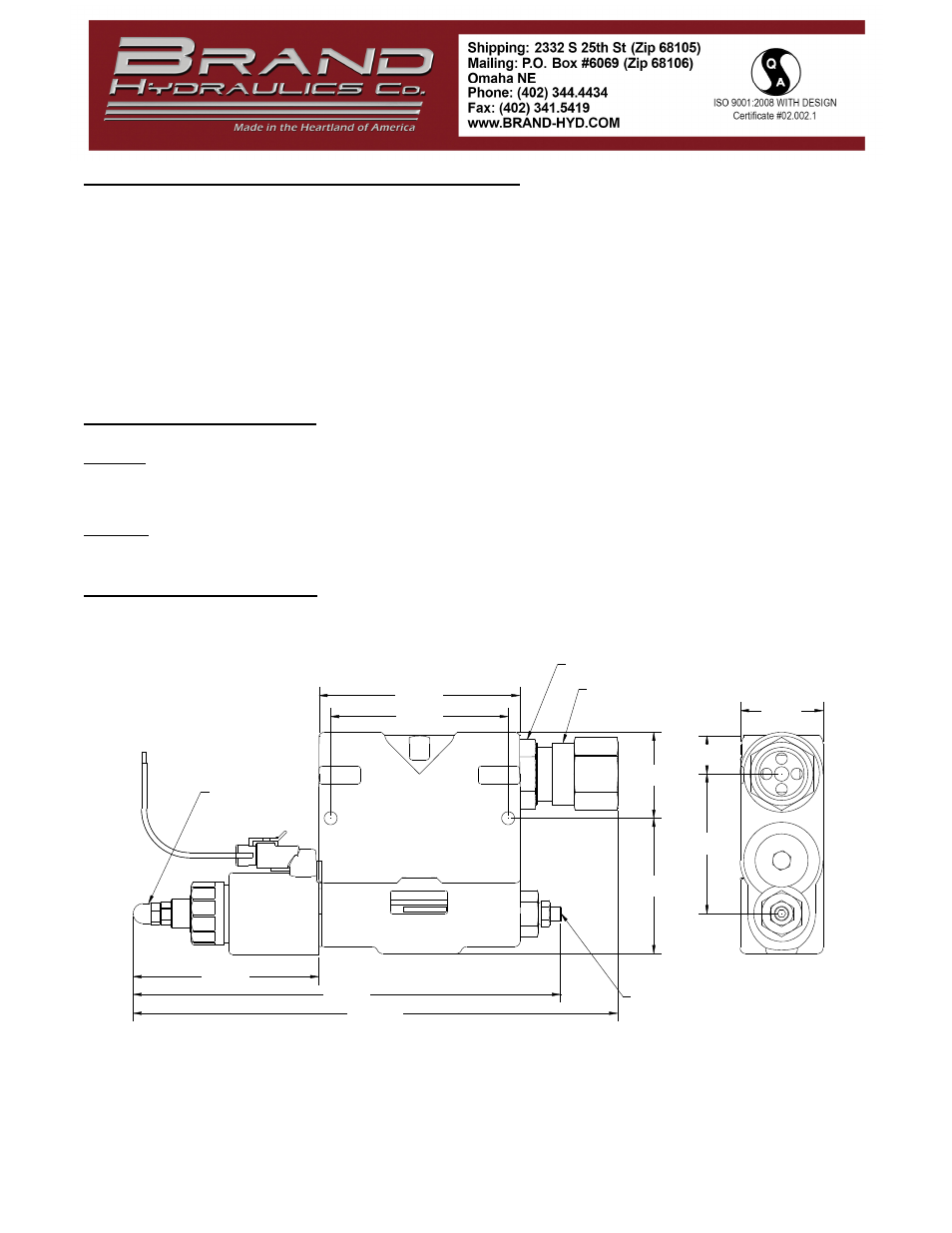

DIMENSIONAL DATA:

Figure 1: Dimensional Data for EFC valves (EFC with relief shown).

IN

CF

EX

S.N.

BRAND HYDRAULICS

RELIEF LOCK NUT

RELIEF ADJUSTING FITTING

USED TO SET CRACK OPEN

DO NOT ADJUST

MANUAL

OVERRIDE

3.03"

0.83"

1.85

2.94"

1.75"

4.44"

3.88"

10.57"

9.33"

4.05"