BVA Hydraulics J13300 User Manual

Page 4

4

MAINTENANCE

NOTICE: Use premium quality hydraulic jack oil. Avoid mixing different types of fluid and NEVER use brake fluid, turbine oil,

transmission fluid, motor oil or glycerin. Improper fluid can cause premature failure of the jack and the potential for sudden and

immediate loss of load.

Adding Oil

1. With saddle fully lowered set jack in its upright, level position. Locate and remove oil filler plug/screw.

2. Fill with oil even with the bottom of the oil filler hole. Reinstall the oil filler plug/screw.

Changing Oil

For best performance and longest life, replace the complete fluid supply at least once per year.

1. With saddle fully lowered set jack in its upright, level position. Locate and remove oil filler plug/screw.

2. Lay the jack on its side and drain the fluid into a suitable container.

NOTICE: Dispose of hydraulic fluid in accordance with local environmental regulations.

3. Fill with oil even with the bottom of the oil filler hole. Reinstall the oil filler plug/screw.

Lubrication

A periodic coating of light lubricating oil to pivot points will help to ensure that pump piston linkages move freely. Do not apply

oil to saddle area.

Cleaning

Periodically check the pump piston and ram plunger/saddle for signs of rust or corrosion. Clean as needed and wipe with a clean,

oil soaked rag. Do not apply oil to saddle area.

Storage

Store the jack with pump piston, ram plunger/saddle fully lowered and release valve open, but never more than 1 turn. This will

help prevent rust and corrosion to those critical surfaces.

WARNING: The paint on this product contains lead, a chemical known in the State of California to cause cancer, birth

defects and other reproductive harm. Do not ingest paint chips and keep product away from children. Wash hands after

each use.

!

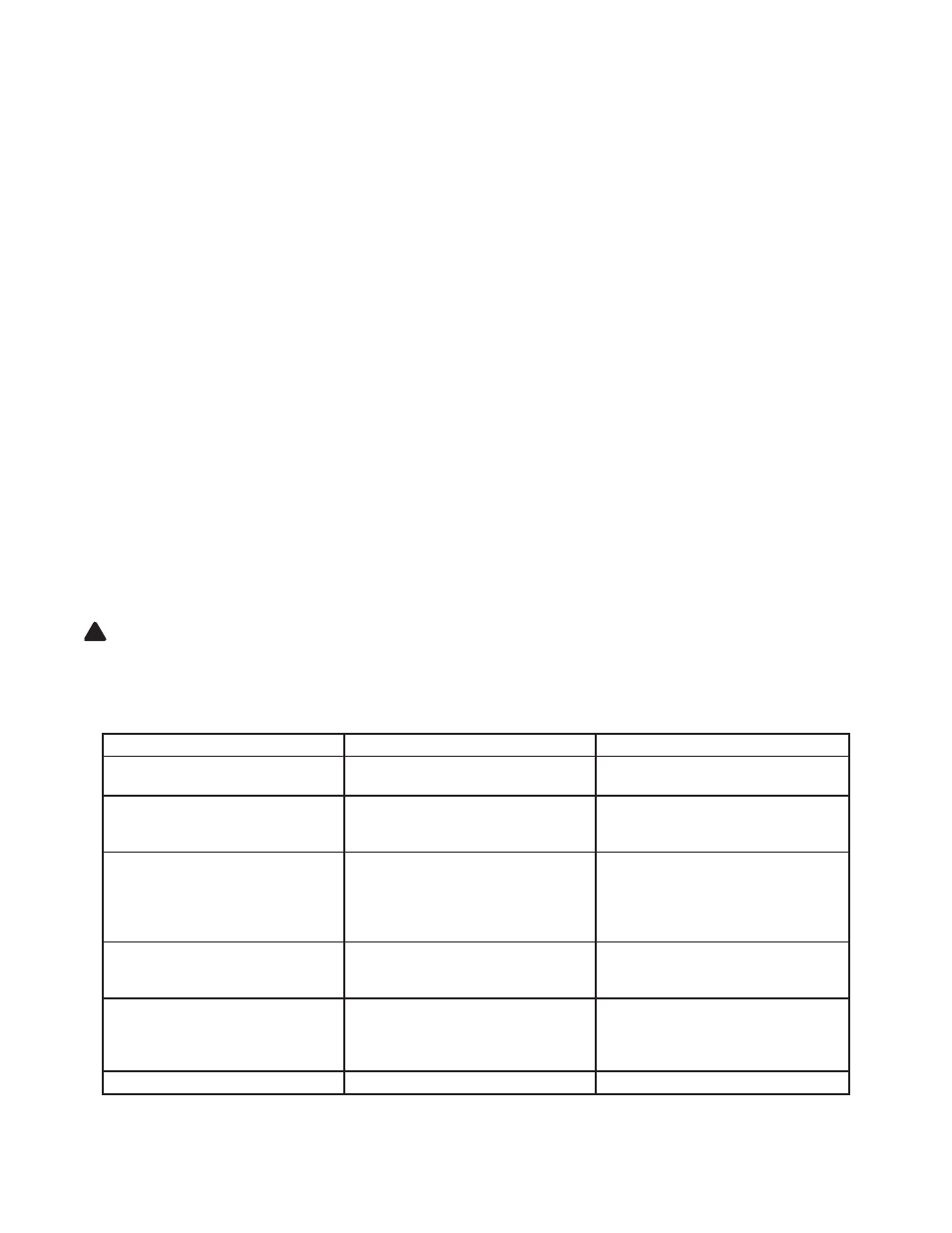

TROUBLESHOOTING

Symptom

Possible Causes

Corrective Action

Jack will not pressurize

• Release valve not tightly closed

• Load is too heavy

• Ensure release valve tightly closed

• Consider higher capacity jack

Jack bleeds off after lift

(load slowly and unintentionally

lowers)

• Hydraulic unit malfunction

• Contact Service Center

While lowering, fluid leaks from

reservoir area.

Jack saddle will not descend to low-

est advertised height.

• Reservoir overfilled

• Ram plunger/cylinder deformed,

seized up in ram cylinder and/or

top nut, likely the result of off-center

loading

• Drain fluid to proper level

• Contact Service Center

Ram plunger will not remain lowered

after released from contact with load

(creeps back up)

• Air trapped in system

• Perform

Bleeding/Venting Trapped

Air procedure.

Poor lift performance

• Fluid level low

• Air trapped in system

• Hydraulic unit malfunction

• Ensure proper fluid level

• Perform

Bleeding/Venting Trapped

Air procedure.

• Contact Service Center

Will not lift to full extension

• Fluid level low

• Ensure proper fluid level