Bray 63 N4 Series User Manual

Page 3

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written

consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed

knowledge and experience with their application.

SERIES 63 N4 Operation & Maintenance Manual

Manual Number OM-63/N4-001

Date: September 2, 2010 Page 3 of 5

4-Way Dual Solenoid Operation

• Solenoid A Last Energized: Flow is from

pressure port 1 to port 2 and from port 4 to

port 5. Port 3 is closed. Slight pilot exhaust

apparent when solenoid A is de-energized.

• Solenoid B Last Energized: Flow is from

pressure port 1 to port 4 and from port 2 to

port 3. Port 5 is closed. Slight pilot exhaust

apparent when solenoid B is de-energized.

4-Way Dual Solenoid (5/2)

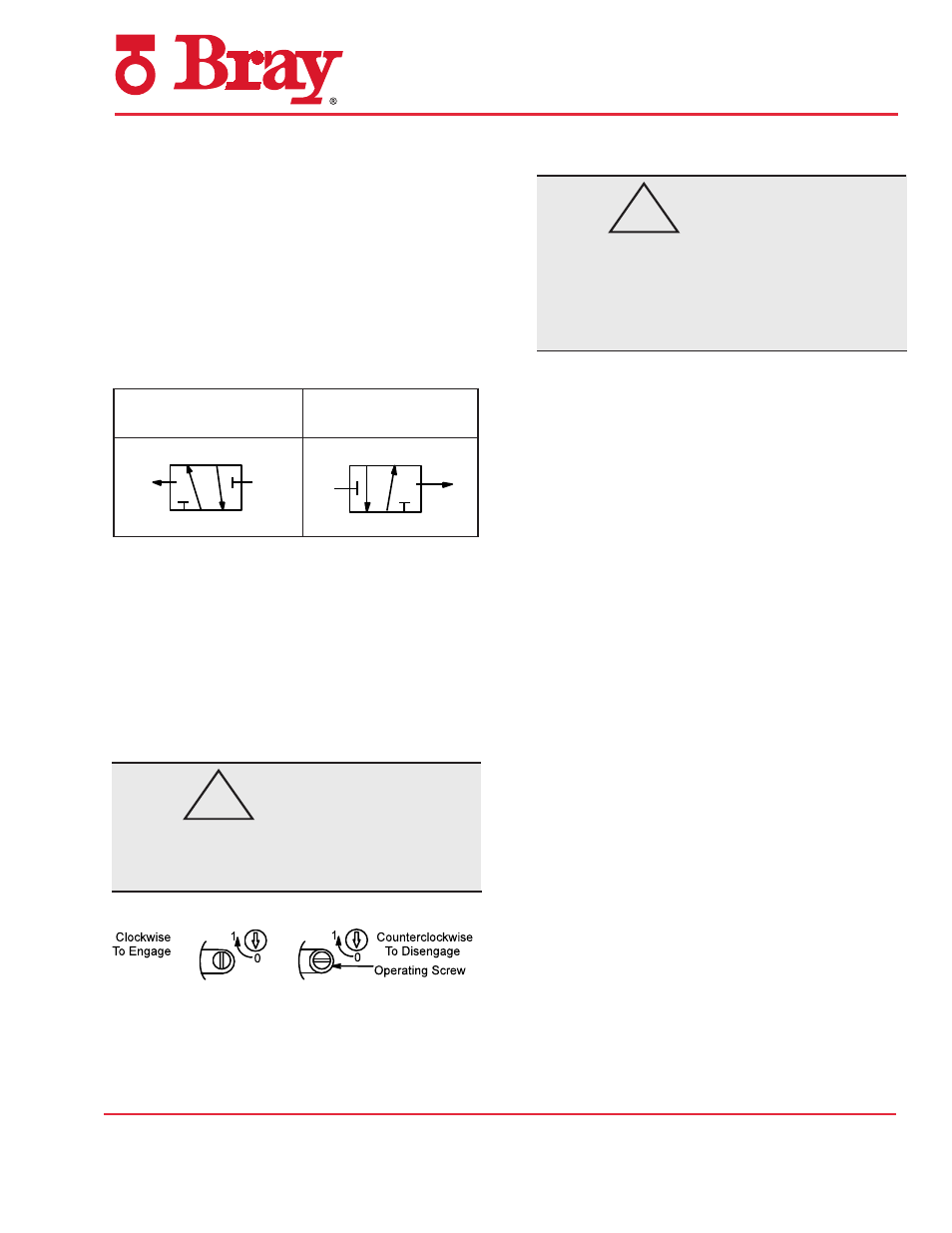

Manual Operator (See Figure 1)

Manual operator provides manual operation

when desired or during an electrical power out-

age. To engage manual operator, rotate screw

clockwise as far as possible to “1”. Valve will

now be in the same position as when the sole-

noid is energized. To disengage manual op-

erator, rotate screw counterclockwise as far as

possible to “0”.

CAUTION

To prevent malfunction be sure to turn screw

counterclockwise to “0” before operating

valve electrically.

Figure 1. Manual Operator (partial view)

Installation

WARNING

Check nameplate for correct catalog number,

pressure, voltage, frequency, and service. Never

apply incompatible medium or exceed pressure

rating of the valve. Installation and valve main-

tenance to be performed by qualified personnel.

Future Service Considerations

Provision should be made for performing seat leak-

age, external leakage, and operational tests on the

valve with a nonhazardous, noncombustible fluid.

NOTE: For temperatures below 32°F (0°C)

moisture-free air must be used.

Positioning

Valve may be mounted in any position.

Flow Selection and Mounting (See Figure 2)

Two flow plates are provided with each valve.

Flow plates are marked (3/2) for 3-way or (5/2)

for 4-way. See Figure 2 for proper orientation of

flow plate, gaskets, mounting screws and locating

set screw. Then proceed as follows:

1. If required, install locating set screw using a 2

mm hex key wrench.

2. Install Port 2 and Port 4 gaskets and flow gas-

ket on flow plate.

3. Position flow plate and solenoid valve on

actuator. Then install two socket head cap

screws in offset center holes on either side.

Hand thread screws a few turns into actuator.

Then tighten screws evenly using a 4 mm hex

key wrench.

Piping

There is pilot exhaust from the top of the solenoid

when the solenoid is de-energized. The pilot ex-

haust may be connected to the main exhaust if the

air or inert gas cannot be exhausted directly to the

atmosphere. An exhaust protector is provided in

the top of the plugnut/core tube assembly to pre-

vent debris from entering pilot exhaust.

Solenoid “A”

Last Energized

Solenoid “B”

Last Energized

B

A

Pilot

Exh.

Pilot

Exh.

4

2

3 1 5

B

A

Pilot

Exh.

Pilot

Exh.

4

2

3 1 5

!

!