Configuration diagrams, Maintenance, Troubleshooting – Bray 62 Series User Manual

Page 2: Tools required

SERIES 62 Solenoid Pilot Valve

Operation & Maintenance Manual

Manual Number OM-62-001 • Date: March 24, 2014 8:28 AM • Page 2 of 2

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Before work, switch off the electrical power supply to

de-energize all components

Depending on the voltage, electrical components must be

provided with a ground/earth connection and satisfy local

regulations and standards.

The Bray Series 62 solenoid valve is designed for contin-

uous duty service. To avoid any possibility of damage or

injury do not touch the solenoid which can become hot

under normal operating conditions. If the solenoid valve

is easily accessible, the installer must provide protection

against accidental contact.

Maintenance.

Prior to any maintenance work or returning to operation, shut

off supply to the pilot solenoid valve, depressurize and vent

the valve in order to prevent injury or damage.

Cleaning: maintenance of the valve depends on the oper-

ating conditions. They must be cleaned at regular intervals.

During servicing, the components must be checked for ex-

cessive wear. If operation cycle is slow, ensure proper supply

pressure and that there is no unusual noise or leak detected.

Sound emission: the sound emission depends on the appli-

cation, supply medium and nature of the equipment used.

Exact determination of the sound level can only be carried

out by the user having the valve installed in their system.

Preventive maintenance: Operate the pilot solenoid

valve monthly to check function. Should any difficulties or

questions arise during installation and maintenance, please

contact a Bray representative.

Troubleshooting

:

Incorrect supply pressure: check the supply pressure,

Minimum air supply – 22 psi (1.5 bar)

Maximum air supply - 130 psi (9 bar)

Tools Required

Phillips (cross drive) screwdriver, to assemble and disassem-

ble solenoid coil to pilot valve

Small flat blade screwdriver, to engage disengage manual red

close button.

5/32”or 4mm hex screwdriver (Allen wrench), to fasten the

solenoid pilot valve to pneumatic actuator.

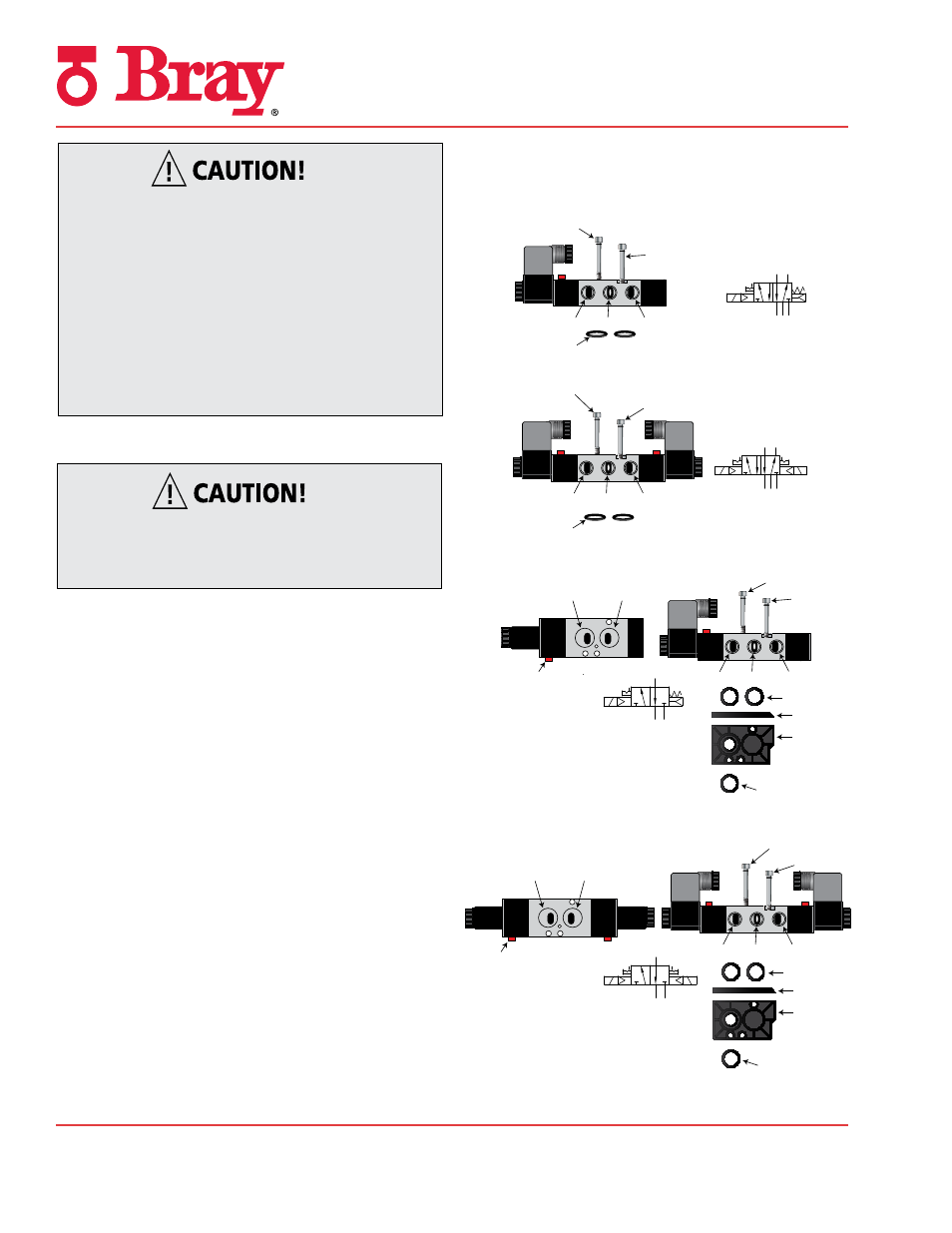

Configuration Diagrams

Figure 3

3/2 for Single Acting/Spring Return Valve

(Single Coil)

Mark

3 1

4

Figure 4

3/2 for Single Acting/Spring Return Valve

(Double Coil)

Mark

2

1

3

Figure 1

5/2 for Double Acting Solenoid Valve

(Single Coil)

Mark

2

4

5

1

3

Figure 2

5/2 for Double Acting Solenoid Valve

(Double Coil)

Mark

3 1 5

4

2

Port 2

Port 4

Manual Override

Port 1

Port 3

Port 5

Port 2

Port 4

Manual Override

Port 1

Port 3

Port 5

Port 1

Port 3

Port 5

Port 1

Port 3

Port 5

O-Rings

O-Rings

Long Screws

Short Screws

Long Screws

Short Screws

Long Screws

Short Screws

Long Screws

Short Screws

O-Rings

Air Flow Plate Side

Air Flow Plate

O-Ring

O-Rings

Air Flow Plate Side

Air Flow Plate

O-Ring