Bray S85 User Manual

Page 2

Installation and Maintenance Manual

Series 85 Ball Valves

Date: August 2011 / Page 2 of 2

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2011 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

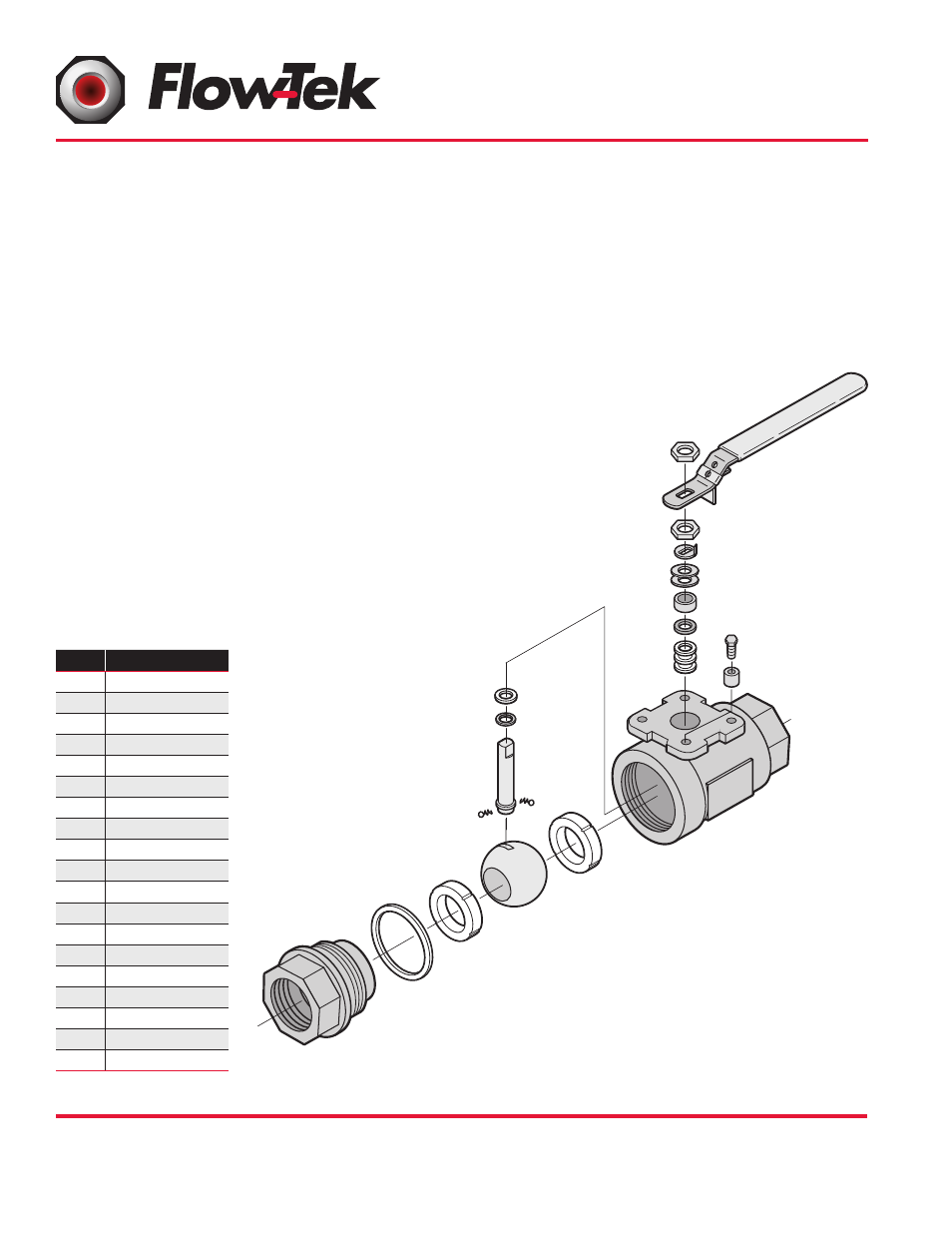

ASSEMBLY

1. Install the thrust washer on stem O.D.

2. Install stem packing in valve body.

3. Insert stem into body, taking care not to pinch or

nick stem packing.

4. Install seat in the rear of the body cavity with the

spherical curvature facing the mating ball.

5. Insert ball in body, care should be taken not to

scratch the ball during installation.

6. Insert seat in threaded end cap so that spherical

curvature is facing the ball. Tighten end cap

tightly.

7. Tighten packing sleeve nut.

8. Place handle on assembly and tighten stem nut.

9. Safe and proper bench testing is required before

re-installing to service. Ensure that valve operates

smoothly.

WARNING: DO NOT REMOVE ANY VALVE PARTS

WHILE LINE IS UNDER PRESSURE! UNDER NO

CIRCUMSTANCES! LINE MUST BE DEPRESSURIZED

BEFORE DEISASSEMBLY. VALVE SHOULD BE CYCLED

TO ASSURE THERE IS NOT PRESSURE IN VALVE CAVITY.

4

3

4

6

2

1

14

11B

15

18

19

26

26

25

29

28

23

24

11A

12

10

5

Item Name

1

Body

2

End Cap

3

Ball

4

Seat*

5

Stem

6

Body Seal*

7

Anti-Static Device

8

Thrust Bearing*

9

Thrust Washer*

10

Stem Packing*

11

Packing Gland

12

Belleville Washer

13

Tab Lock Washer

14

Stop Set Sleeve

15

Stop Bolt

16

Handle

17

Nut

18

Handle Sleeve

19

Locking Device

*Parts included in the repair kits

This brochure is general in nature and manufacturer

reserves the right to change dimensions, materials or to

make design improvements