Øb øf øs c1 c e – Bray F15 & F30 User Manual

Page 3

Installation and Maintenance Manual

F15/F30 Ball Valves

Date: August 2011 / Page 3 of 5

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2011 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

10. Cycle the valve slowly, with a gentle back and forth

motion, to build gradually to the full quarter turn. By

cycling slowly, the seat lips will assume a permanent

seal shape against the ball. A fast turning motion,

at this point, may cut the seats before they have a

chance to form the proper seal.

11. Test valve, if possible, prior to placing valve hack into

line position. WARNING: If not properly secured,

the valve can separate from the pressure source,

resulting in possible injury. Always join the valve

to companion.

12. flanges of same pressure rating as valve and secure

with a full set of flange bolts.

Table 1

BODY BOLT TORQUE

VALVE SIZE F15 (lb.in.) F30 (lb.in.)

1/2”

140

140

3/4”

140

140

1”

210

210

11/4”

210

210

1-1/2”

550

550

2

550

550

2-1/2”

550

550

3”

550

1000

4”

550

1000

6”

1000

1000

8”

1000

1450

10”

1450

2400

12”

1450

3600

TEST AS FOLLOWS

1. Secure valve to a test future by means of a mating

flange with full bolting and a suitable gasket. Orient

valve so seat to he tested is facing up.

2. Introduce 50 to 100 psig air. Partially cycle the valve,

under pressure, and then slowly close to make sure

the cavity is pressurized (use hearing protection).

Pour water into the upper port to cover the ball

and visually check for bubbles. If bubbles appear,

pour the water out, cycle the valve several times

and recheck. To check for leakage in the other port,

reverse the valve and introduce air pressure to the

port just checked.

3. Check stem seal at this time by coating the gland

area with a soapy water solution. If leakage occurs,

tighten stem seal just until leakage stops.

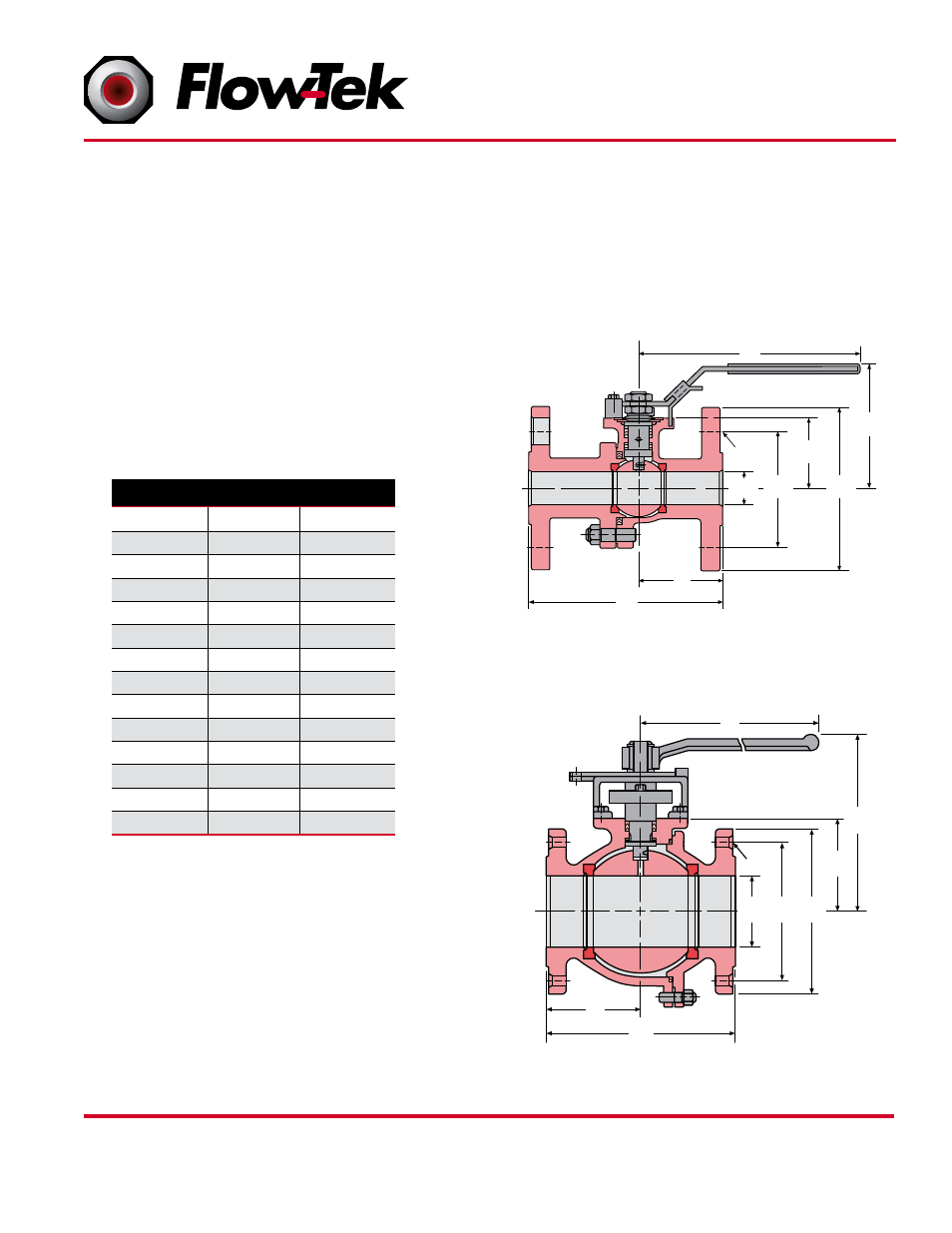

SECTION VIEW ½” - 2” VALVES

Dimensions may be found in product literature

SECTION VIEW 2-1/2” - 12” VALVES

A

D

N-øT

øB

øF

øS

C1

C

E

A

E

D

4-øT

C

øF

C1

øS

шB