Atec Teseq-Schaffner-NSG-5600 User Manual

Page 2

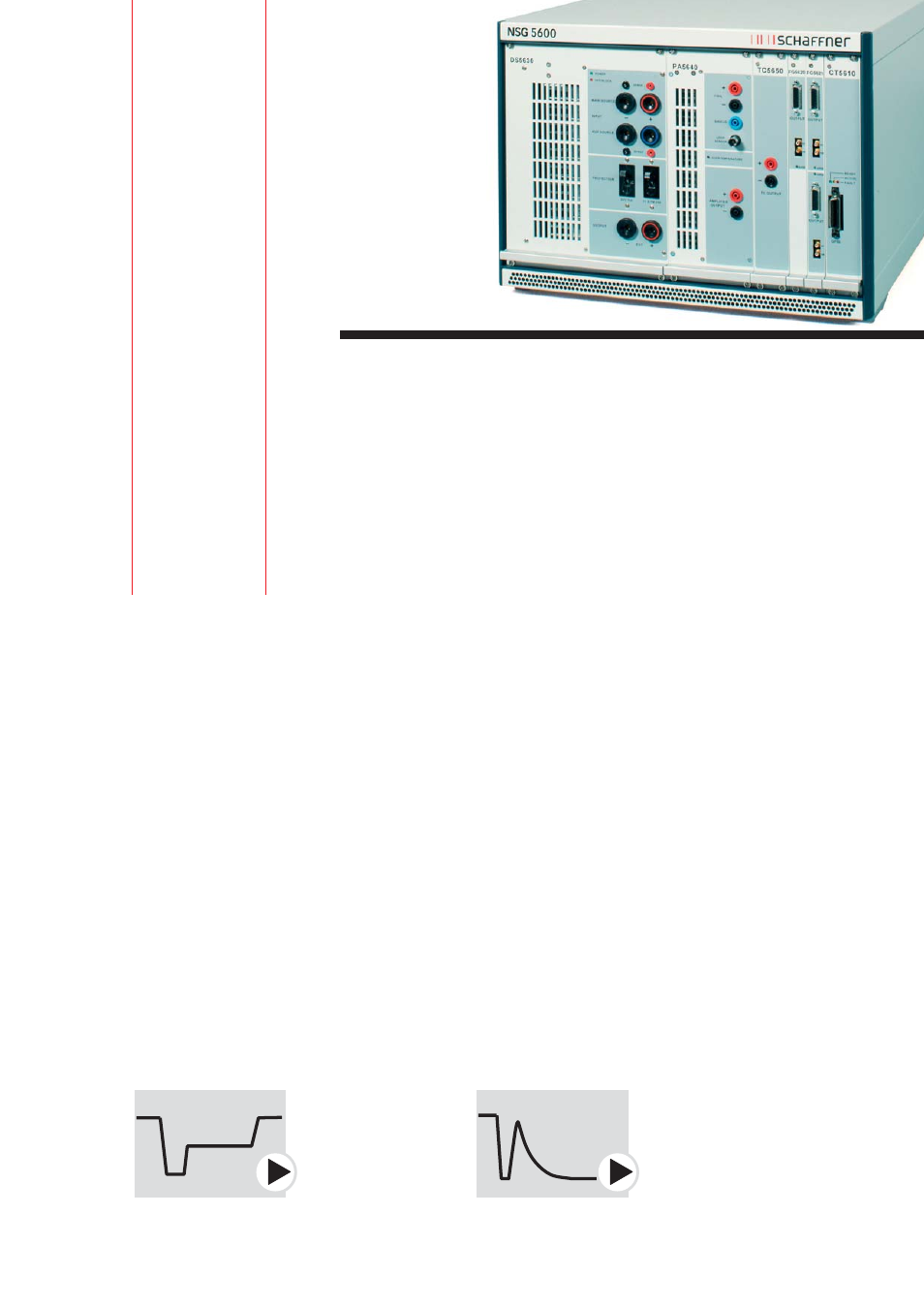

NSG 5600.

Designed to be used either alone or in

combination with a NSG 5500 system, the NSG 5600

is designed to simulate events that include voltage

dropouts, sinusoidal noise and other events super-

imposed on the automotive battery: Dips and drops,

and ISO and SAE pulse 2b and pulse 4 and other

starting profiles. The NSG 5600 is the leader in syn-

chronized voltage variations, such as power cycling

tests (on up to four FGs) as required by various stan-

dards such as CI 230 defined in the Ford ES-XW7T-

1A278-AB and AC standards. Additionally, the

NSG 5600 may be configured for magnetic field

immunity testing. The basic NSG 5600 includes one

FG 5620 but additional capability may be added

using any of the modules on the following pages.

NSG 5600 concept.

Schaffner continues to utilize its

well accepted modular concept of a 19” basic chassis

containing all the power supply components and,

if required, the sinusoidal burst-transformer, the

control and signal bus boards as well as the com-

mon inputs and outputs for the safety circuits and

signals for the expanded control and monitoring of

the test. The CAN-bus, already well known in auto-

motive technology circles, is used as the system bus.

Therefore, as with the complimentary NSG 5500,

Schaffner’s modular concept, new capabilities can

be quickly implemented. Modular and flexible test

systems equal protection of investment for the user.

Schaffner offers rack-mounted solutions with suit-

able internal cabling and mains control panel as

accessories, configured to the user’s needs.

Utilizing the only automotive EMC specific synchronized, multi-channel function

generator (FG) in the world, the software integrates the various system com-

ponents seamlessly into the overall system concept with uniform operating pro-

cedures and user guidance together with a comprehensive test result reporting

facility.

NSG 5600

Complex voltage variations,

magnetic field test, sinusoidal burst