Atec Vanguard-CT7500 User Manual

Page 3

3

Breaker Initiate Features

A built-in solid-state initiate device is used to

operate a breaker from the CT-7500 S2. The

operational modes include Open, Close, Open–

Close, Close–Open, and Open–Close–Open.

Multiple operations, such as Open–Close and

Open–Close–Open, can be initiated by using

programmable delay time or by sensing a break-

er’s contact condition.

A built-in Hall-effect current sensor records

the Trip/Close current level and duration. The

breaker’s operate-coil current waveform dura-

tion (effectively, a performance "fi ngerprint" or

"current profi le") can be used as a diagnostic

tool for analyzing a breaker’s performance.

Computer Interface

The CT-7500 S2 can be computer-controlled via

its RS232C or USB interface. Windows® based

BreakerAnalysis software is provided with each

unit. Using this software, circuit-breakers can

be timed from the PC. Test records can be re-

trieved from the CT-7500 S2 and then stored on

the PC for future analysis and report generation.

Circuit-breaker test plans can also be created on

the PC and transferred to the CT-7500 S2. Ad-

ditionally, test records can be exported in Excel,

PDF, and XML formats for further analysis.

CT Input

One non-contact AC current sensor is used to

monitor circuit breaker on-line current for the

“on-line” timing mode.

Internal Test Record and Test

Plan Storage

Up to 150 test records can be stored in Flash EEPROM.

Test records can be retrieved and printed on the built-in

thermal printer, or they can be transferred to a PC via the

unit’s RS232C or USB interface.

Up to 99 circuit breaker test plans can be stored in Flash

EEPROM. Test plans are comprised of all circuit-breaker

performance specifi cations (stroke, velocity, and con-

tact time). A test plan can be used to immediately test

a circuit-breaker. A pass/fail report is then generated by

comparing actual performance with the specifi cations in

the stored test plan. Test plans can also be generated

on a PC and transferred to the CT-7500 S2 via the unit’s

RS232C or USB interface.

Diagnostic Capabilities

The CT-7500 S2 can perform diagnostics on its internal

electronics. Diagnostics can be performed to verify con-

tact cable connections and to test the travel transducer’s

electronics.

Built-in Thermal Printer

The CT-7500 S2’s built-in 4.5-inch wide thermal

printer can print the breaker contact analysis re-

sults in both tabular and graphic formats.

User Interface

The CT-7500 S2 features a back-lit LCD screen

(20 characters by 4 lines) that is viewable in

both bright sunlight and low-light levels. A rug-

ged, 16-key, membrane keypad is used to control

the unit.

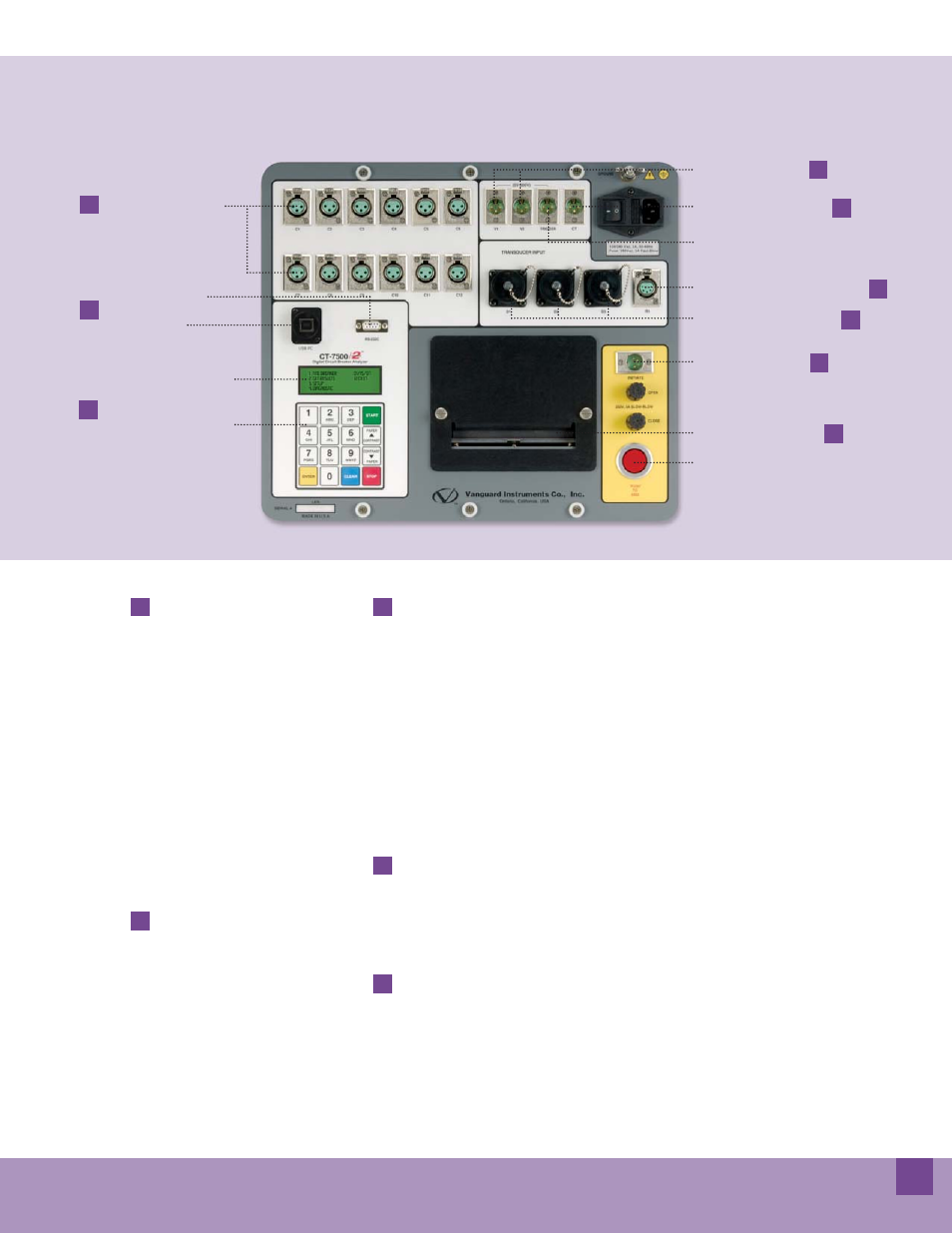

Contact Timing Channels

1

Digital Transducer Connectors

2

Resistor Type Transducer Connector

3

Voltage Input Channels

4

Breaker Initiate Output

5

5

USB PC Interface

RS-232C PC Interface

7

7

AC Clamp-on Current Probe

6

6

4.5" Wide Thermal Printer

8

8

9

Back-lit LCD Screen

(20 characters by 4 lines)

9

Rugged 16-key membrane

keypad

Breaker Initiate Arm Switch

CT-7500 S2 Controls & Indicators

Trigger Input Connector