Acquisition, Flawless data management, Analysis – Atec Panametrics-Olympus-Omniscan-MX2 User Manual

Page 8: Pulse repetition frequency (prf), Saving inspection data file to usb (speed), Maximum file size (mb)

8

www.olympus-ims.com

Acquisition

•

A scan menu for quick and easy configuration of inspection

parameters for manual, one-line, raster, and helicoidal scans.

•

Multiple encoder modes, including Clock, Quadrature, and

Clicker.

•

C-scan configuration for amplitude and position C-scans, and

display setup.

•

Data storage options for full A-scans, S-scans, and/or C-scans.

•

Preconfigured display layouts for easy inspection preparation.

•

PRF auto adjustments for optimized, maximum speed, or

manually-controlled settings.

•

Data storage options for flash card or USB media devices.

•

Real-time data acquisition displays, with the ability to rewrite

data in both scan directions when using an encoder.

•

Easy to interface with encoded scanners.

•

Different gate-synchronization capabilities.

Pulse Repetition Frequency (PRF)

OmniScan MX

OmniScan MX2

40% better

Saving Inspection Data File to USB (speed)

OmniScan MX

OmniScan MX2

Up to 400% better

Maximum File Size (Mb)

OmniScan MX

160 Mb

OmniScan MX2

300 Mb

Flawless Data Management

An SD Card is used to store data for easy transfer to a computer.

The SD card can also be inserted and removed without having

to reboot the unit. In addition, data can be transferred to exter-

nal media using the USB 2.0 port. The OmniScan MX2 provides

data transfer speeds up to 400% faster than the OmniScan MX

(depending on the device used).

Analysis

•

An extensive display menu for preconfigured multigroup and

multiprobe inspection layouts.

•

Data, reference, and measurement cursors for defect sizing

and reporting.

•

Extensive Readings database for trigonometry, flaw statistics on

axes, volumetric position information, code-based acceptance

criteria, corrosion mapping statistics, etc.

•

All Readings are available online, and are also available off-

line when full A-scans are saved in data files.

•

Linked displays for interactive analysis of A-scans, B-scans,

S-scans, and C-scans for multigroup and multiprobe

inspections.

•

Optimized preconfigured layouts for quick and simple length,

depth, and height sizing of flaws for code-based or non-code-

based inspections.

•

Interactive off-line gate repositioning.

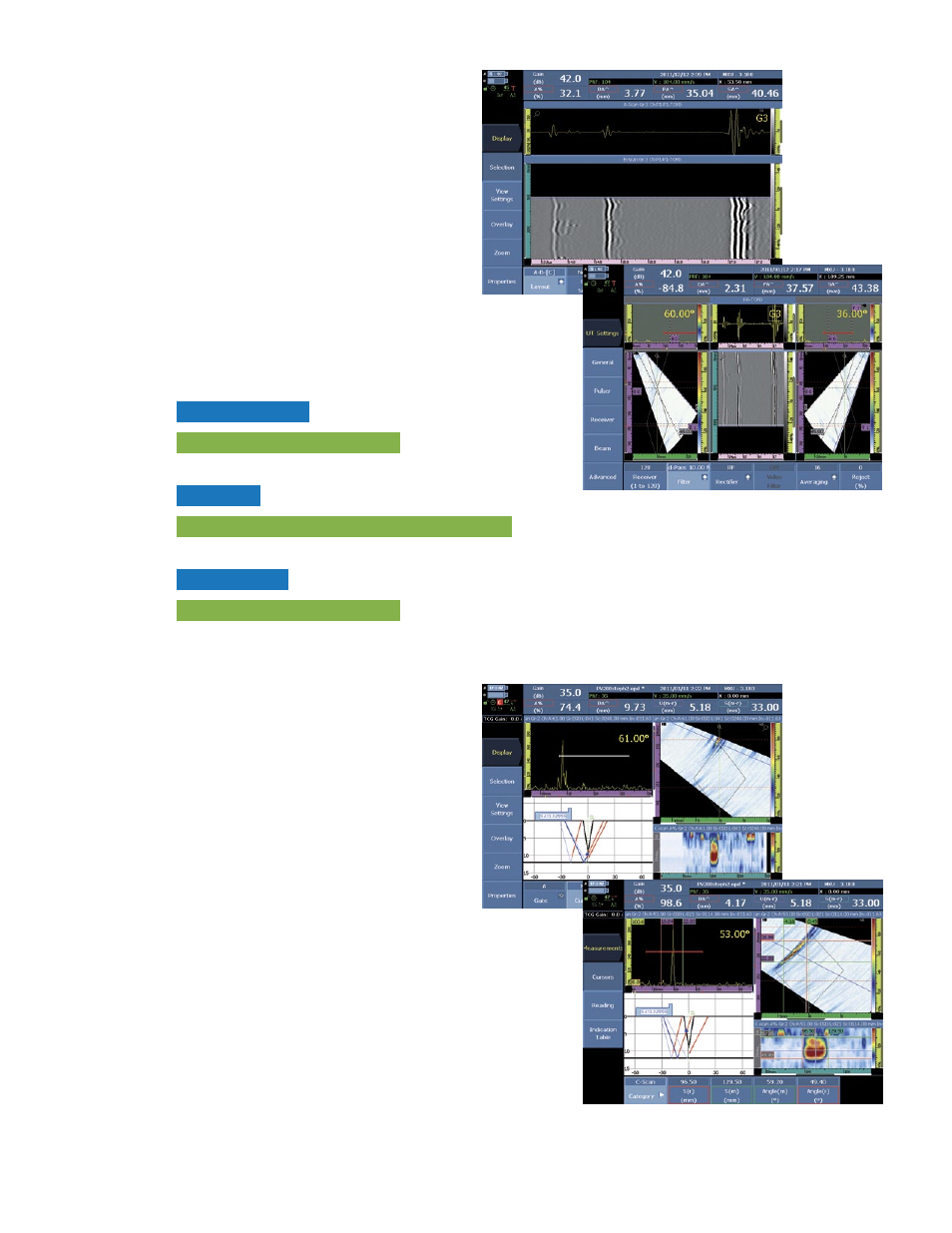

Top: Data acquisition

displaying TOFD.

Right: Data acquisition

displaying two phased

array channels and

TOFD.

Weld inspection

display showing the

position of indications

in the RayTracing

display.