Atec Solar-6220-1A User Manual

Page 5

above 5 KHz when using an EMI meter capable of

measuring 1.0 microvolt into 50 ohms. For EMI

meters such as the NM-7A and the EMC-10E,

the meter sensitivity is a decade better and

it is possible to measure EMI currents of

.005 microamperes at 5 KHz and above.

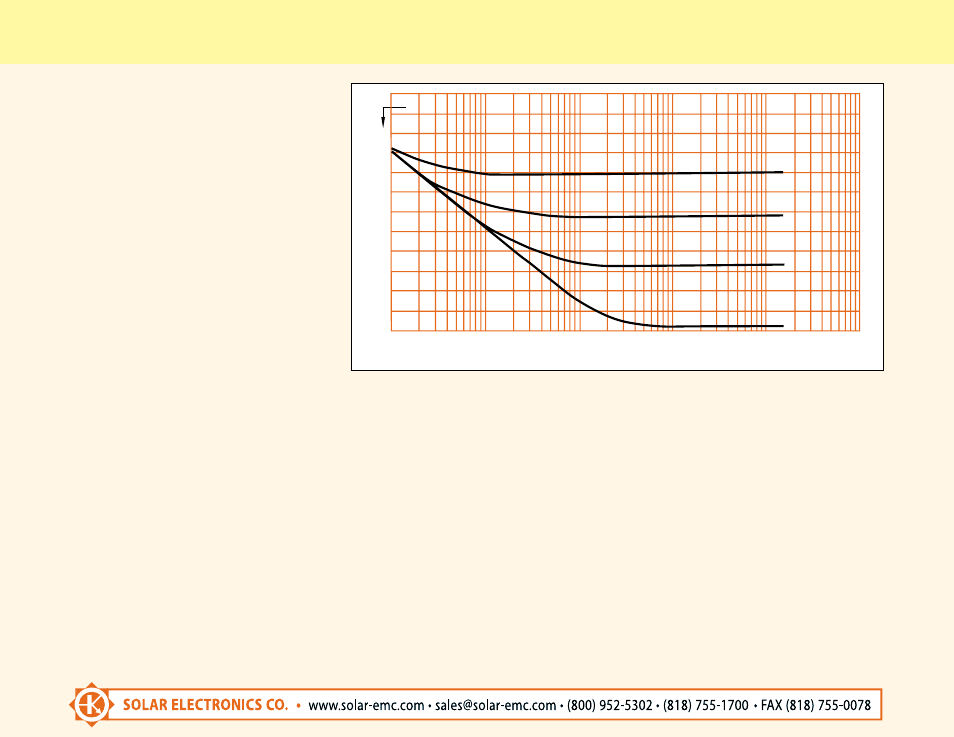

FLATTENING THE RESPONSE

At a sacrifice of sensitivity, the upper portion of

the frequency vs. correction factor curve can be

flattened to provide a constant correction factor

from about 1 KHz up to 150 KHz. This is depicted

in curve #2 of Figure 3, where a -20 dB correction

is suitable over this part of the frequency range.

The flattening is obtained by loading the primary

with a suitable value or resistance. The resistance

value used in this example is 10 ohms. The

flattening still allows the measurement of a

0.1 microampere signal when using an EMI meter

with 0.1 microvolt sensitivity. An advantage

of this response curve is the sloping correction

at frequencies below 1KHz which acts like a high

pass filter to remove some of the power line

harmonics from wideband measurements.

If you are only interested in frequencies above

150 Hz, a 2 ohm resistor is all that is needed. See

curve #3.

STILL MORE FLATTENING

Like the girdle ads say, you can firmer and flatter,

with a loss in sensitivity , by further reducing the

value of the shunt resistor. This is illustrated

in curve #4 of Figure 3 where a 0.5 ohm shunt

resistor (Solar Type 6920-0.5) is connected

across the transformer primary winding used as

an output winding to the EMI meter. The overall

flatness is achieved at the sacrifice of considerable

sensitivity, but the sensitivity is well under the

requirements of existing specifications and the

correction network utilizes no active elements.

LIMITATIONS OF THE METHOD

When measuring EMI current on d.c. lines, there

are no problems, but on a.c. lines there are limita-

tions. The a.c. voltage drop across the winding (S)

due to power current flowing to the test sample

is the principal problem. This voltage induces

twice as much voltage in the output winding (P)

at the power frequency. Since we prefer to limit

the power dissipation in the 50 ohm input to the

EMI meter so that it will not exceed 0.5 watts, the

induced voltage must be kept below a safe limit.

For 400 Hz lines, the power frequency current

must not exceed 16 amperes to avoid too much

400 Hz power dissipation in the input to the EMI

meter. Also, the resistance ‘R’ used across the

output winding (P) must be at least a 50 watt

rating on 400 Hz lines. This resistor should be

noninductive to avoid errors due to inductive

reactance.

THINGS TO BE WARY OF

The 10

ȖF feed-thru required by present

day specs has appreciable reactance at 30 Hz

(

LJ54 ohms) and acts to reduce the actual EMI

current flowing in the circuit. This means less

trouble in meeting the spec, but when calibrating

the test method described herein, it is wise to

short circuit the capacitor.

In the case where the input circuit to the

EMI meter is reactive, such as the EMC-10E, it is

necessary to use a minimum loss ‘T’ pad at

the input to the meter. The Eaton NM-7A and

NM-12/27A units do not require this pad and

its loss.

DETERMINING THE NARROWBAND

CORRECTION FACTOR

The test setup of Figure 4 describes the simple

method of determining either the transfer

AN622001 (continued)

dB TO BE ADDED TO EMI

METER READING (IN dB) TO

OBTAIN dB /

ȖA.

+20

+10

0

–10

10

100

1K

10K

FREQUENCY HERTZ

100K

1M

–20

–30

CURVE #4

CURVE #3

R

LJ0.5 OHM

R

LJ2 OHMS

CURVE #1

CURVE #2

R=

∞

R

LJ10 OHMS

FIGURE 3 – TYPICAL CORRECTION DATA VS. FREQUENCY

61