Bite, 2 and bite 2p battery impedance test equipment – Atec Megger-BITE Series User Manual

Page 3

BITE

®

2 and BITE 2P

Battery Impedance Test Equipment

Test Procedure

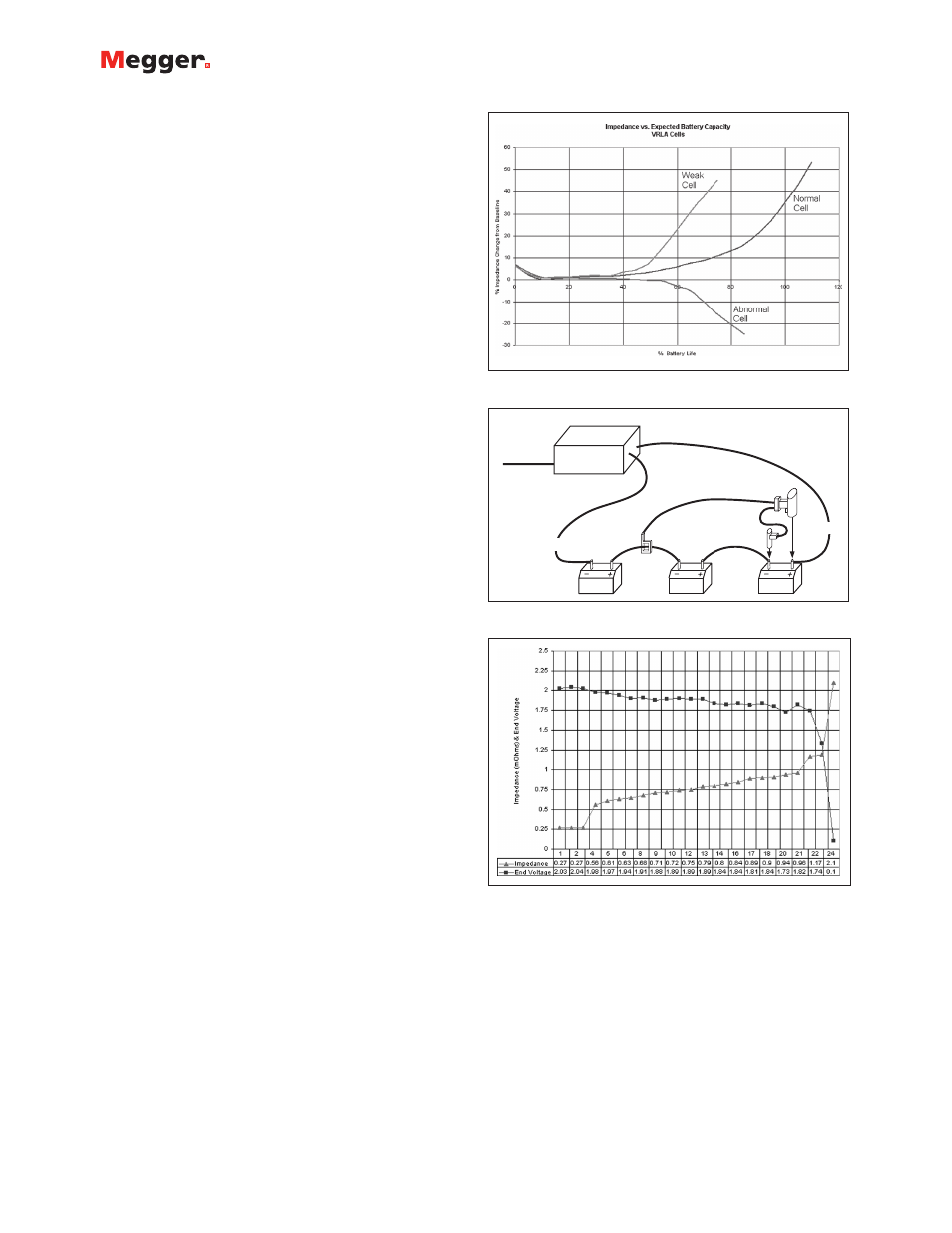

The BITE 2 and BITE 2P work by applying a capacitively

coupled ac test signal across the battery string while on-

line. The receiver and potential probe are placed at the cell

terminals to measure the signal and resulting voltage drop

for each cell/jar. During each measurement, impedance is

calculated following Ohm’s Law, displayed on the LCD and

stored. The instruments also measure, display and record

dc voltage and interconnection (strap) resistance to help

determine the overall condition of the entire battery string’s

electrical path from terminal plate to terminal plate. The

also measure ac ripple current, a charger parameter.

The BITE 2 and BITE 2P receiver stores the readings in

its internal memory. These measurements, along with

other maintenance data such as ambient and pilot cell

temperatures and ac ripple current, assist in determining

the overall condition of battery systems. Figure 3 shows a

typical test setup.

Interpretation of Readings

Data produced by the BITE 2 and BITE 2P can be

interpreted in several modes: instantaneous, short-term and

long-term time frames. An impedance distribution plot, as

shown in Figure 4, assists in the analysis.

Instantaneous Interpretation

The operator can enter a baseline value from either the

impedance measurements obtained at commissioning

or from the Megger website. The percent changes from

baseline for warning and fail levels are entered, but 20

percent and 40 percent are the default settings. The LCD

on the receiver will display the status of the cell for a few

seconds before proceeding to the next cell. The status of

each cell/jar will be printed on the Battery Analysis Report.

Short-Term Interpretation

Impedance readings for individual cells can be used in

the short term to compare with the average impedance

readings for the entire battery string. Individual cell values

with deviations of more than ±15% for flooded lead-acid,

±35% for VRLA, and 50% for NiCd cells from the battery

string average typically indicate a problem with that cell.

Megger recommends additional investigation of such cells

including a verification of intercell connections and a single

cell load-cycle test.

Long-Term Interpretation

Impedance readings for the entire battery can be used in

the long term to determine replacement criteria. Battery

cell impedance values should be recorded and compared

to previous readings to determine the position of the cell

on the curve of impedance versus cell life as shown in

Figure 2. Based on experience, a variation of ±20% from

baseline for flooded lead-acid, ±40% for VRLA and 50%

for NiCd cells indicate significant change in the electrical

path to warrant serious evaluation of the condition of the

battery system. Megger maintains a database of impedance

values by some manufacturers and battery size/type. For

comparison purposes, this information is available upon

request.

Figure 4. Ascending impedance compared to load test

Figure 3. A typical test setup

Figure 2. Impedance increases with battery age (and weakness)

“CT”

Located

in Battery

Circuit

STRAP

CELL

TRANSMITTER

LINE

VOLTAGE

CURRENT SOURCE

LEAD

CURRENT SOURCE

LEAD

BLACK

RED

SPECIFICATIONS

Application

The BITE 2 and BITE 2P test lead-acid and nickel-cadmium cells

up to 7000 Ah.

Maximum Total Voltage at Current Source Leads

275 V dc (larger battery systems can be sectioned to accommodate

this specification)

Transmitter

Supply Voltage

100 to 130 V, 50/60 Hz, 200 VA max

210 to 250 V, 50/60 Hz, 200 VA max

Source Output Current

10 A nominal, 50/60 Hz operation