Bite, 2 and bite 2p battery impedance test equipment, Jumpering out a cell or two – Atec Megger-BITE Series User Manual

Page 2: Clean and/or retorque intercell connectors, Electrical power generation plants, Substations: utility, railroad, industrial, Ups systems, Railroad: signals and communications, substation, Aircraft power supplies, Marine, military features and benefits

BITE

®

2 and BITE 2P

Battery Impedance Test Equipment

At any time while performing a test, the operator can

review the current test results by using arrow keys and

scrolling back through the active test screen. The operator

can also print the active test using the BITE 2P transmitter

printer. If needed, the operator can retest any of the cells

and straps in the current test. Stored data can also be

downloaded via the RS-232 connector directly to a personal

computer or the BITE 2P transmitter printer.

One additional feature of the receiver is that if you are

called away while in the middle of the test, simply shut

down the instrument and it will remember where you left

off in the test.

The clamp-on current sensor is connected to the receiver

during testing and clamped around a convenient intertier

or intercell connection within the loop created by the

transmitter’s current source leads and the battery string. If

the intercell or intertier connection consists of more cables

than the diameter of the clamp-on current sensor can

encompass, the receiver has a split-strap function.

There are optional RopeCTs

TM

available for large buss work.

With the optional bar-code wand, additional information

such as location ID, user ID, ambient and pilot cell

temperatures can be recorded and stored. There is space

on the printout to enter specific gravity readings.

Data, measured and stored in the receiver can be exported

to a PC. It can also be printed to the BITE 2P transmitter

printer where it can be reviewed. Figure 1 shows a sample

printout of a full battery analysis report.

APPLICATIONS

A battery’s internal impedance increases with decreasing

capacity due to various conditions such as age, ambient

temperature, discharge history, etc. See Figure 2. Both the

BITE 2 and BITE 2P measure impedance values and dc

voltage for lead-acid and nickel-cadmium cells up to 7000

Ah capacity.

Impedance finds electrical path problems due to plate

sulphation, post-seal corrosion, dry-out, and poor intracell

and intercell connections. This information lets the operator

determine maintenance needs such as:

n

Cell replacement criteria based on impedance trends.

n

Jumpering out a cell or two.

n

Clean and/or retorque intercell connectors.

n

Shorten the maintenance interval, etc.

Typical installations that can be tested using the BITE 2

and BITE 2P include:

n

Electrical power generation plants.

n

Substations: utility, railroad, industrial

n

Telecommunications facilities: CO, Wireline, Wireless,

MTSO

n

UPS systems

n

Railroad: Signals and Communications, substation

n

Aircraft power supplies

n

Marine, military

FEATURES AND BENEFITS

n

On-line testing requiring no downtime.

n

Enhanced printing and memory functions.

n

Calculates impedance automatically and stores results

for on-site review.

n

Requires no battery discharge.

n

Receiver has an RS-232 connector for downloading stored

data to a personal computer.

n

Reduced test time: less than 15 seconds for each cell.

n

Measures impedance and dc voltage values for all lead-acid

and nickel-cadmium cells up to 7000 Ah.

n

Stores more than 2000 sets of readings in up to

300 tests.

n

Checks charger condition by measuring ac ripple current.

Transmitter

The transmitter provides the capacitively coupled ac test

signal to avoid transients on the dc buss and applies it to

the cells under test via the source leads. Both the BITE 2

and BITE 2P transmitters have an LCD and built-in receiver

charger, while the BITE 2P transmitter features a built-in

printer.

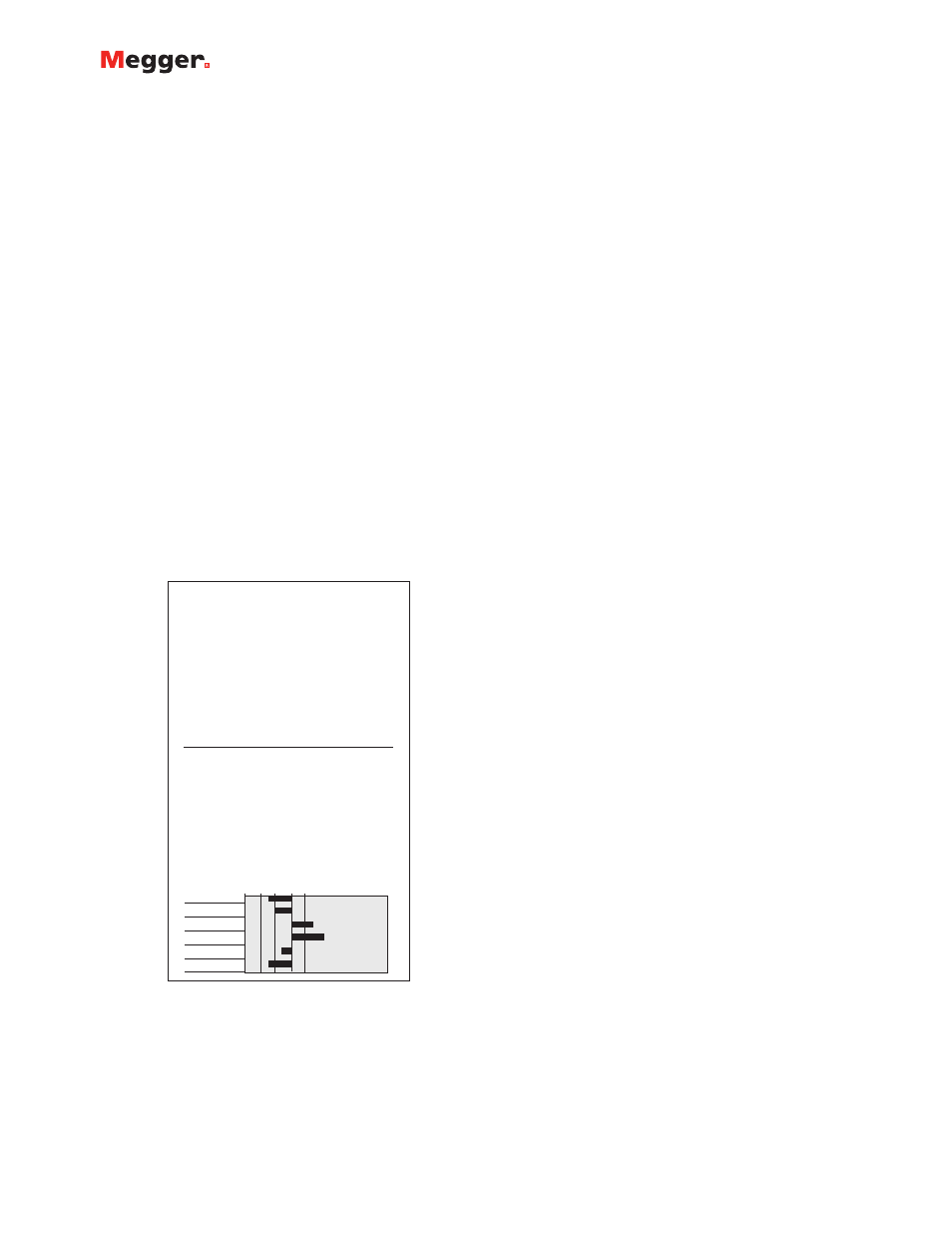

Battery Analysis Report

Location ID:

User ID: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Notes: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Ambient Temp:

Pilot Temp:

Ripple Current:

.01A

Test AC Current: 9.8 A

Multiplier: 1

B/W/F:

11.00 mW/20%/40%

05-SEP-2000

Cell

Sp.Gr.

Zb mW

P/W/F %

RS mW

Volts DC

Time

001

12.09

P 09

0.412

13.52

11:13

002

12.22

P 11

0.407

13.34

11:14

003

14.02

W 27

0.405

13.59

11:14

004

14.54

W 32

0.403

13.48

11:15

005

12.60

P 14

0.042

13.27

11:16

006

12.09

P 09

0.405

13.38

11:17

Cell Impedance Summary

Minimum

Average

Maximum

12.09

12.93

14.54

Percent Deviation from Average

-10 0

10

20

30

001

002

003

004

005

006

Figure 1. Sample battery analysis report