Fiberchekpro automated procedures – Atec JDSU-FBP-P5000 User Manual

Page 2

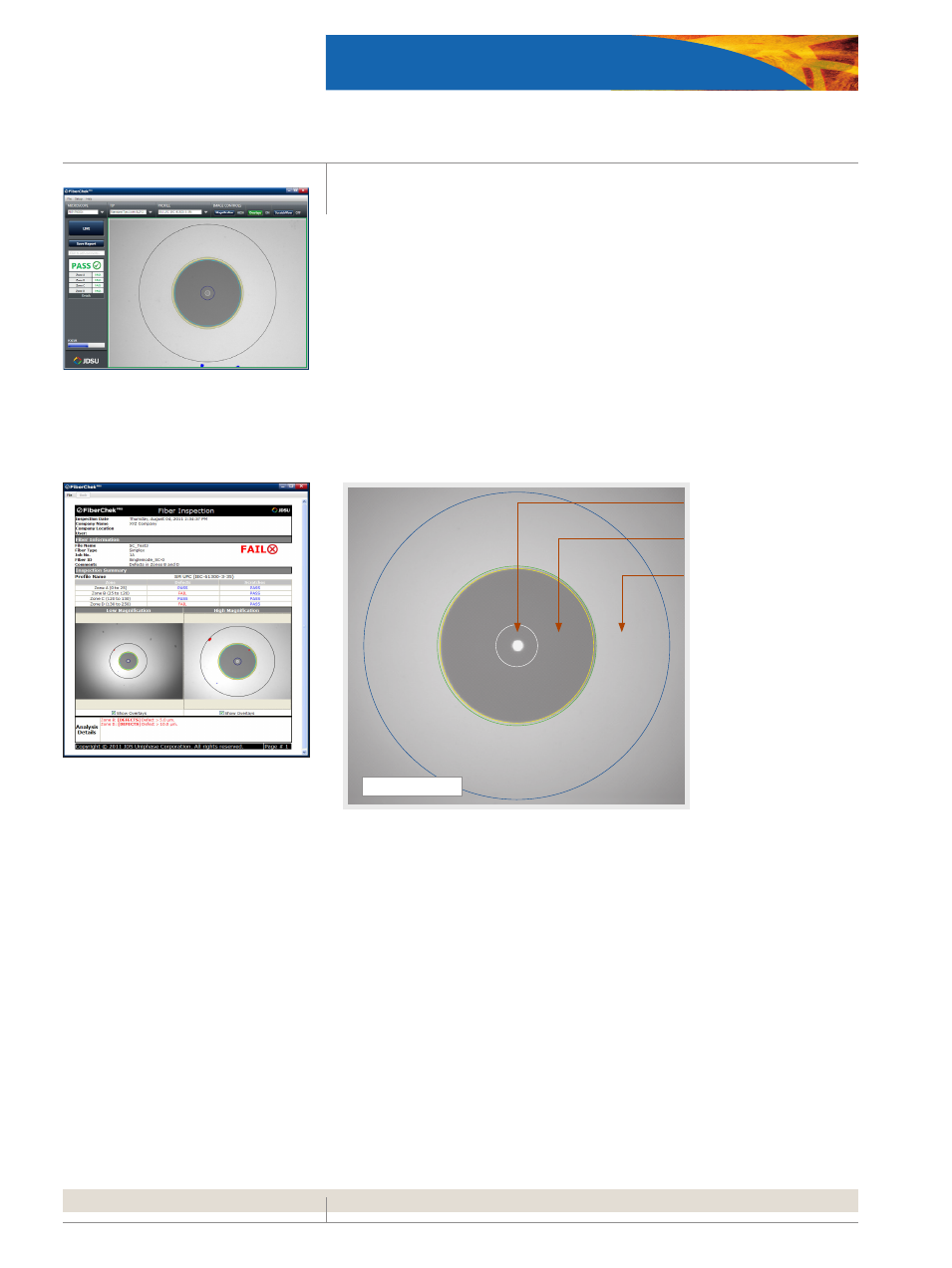

FIBERCHEKPRO AND P5000 DIGITAL PROBE MICROSCOPE

2

Benefits

• Eliminates human subjectivity for

consistent, standardized result when

inspecting and grading fiber

• Configurability allows for user-

defined PASS/FAIL criteria settings

• Standardizes inspection, analysis,

and grading process throughout

fiber networks

• Records and archives results in

HTML or PDF format

FiberChekPRO Automated Procedures

1. Acquires the fiber image

2. Analyzes the image

3. Finds defects and their location to fiber core

4. Measures and evaluates the defects within each specified Zone

5. Determines whether defects within the Zones are acceptable according to the

pre-configured failure criteria for each Zone

6. Displays the results as PASS or FAIL

7. Saves or prints all relative results in designated directory or printer, respectively

As different types of contamination are located and identified, FiberChekPRO

measures the size of each feature, determines its location relative to the core, and

analyzes the collected data using an advanced logarithm to obtain a PASS or FAIL

result based on the user’s desired acceptance criteria.

Because defects and contamination on or near the core surface typically affect the

light transmission most significantly, they require the most aggressive examination.

FiberChekPRO defines the concentric areas around the core as Zones which let

users establish failure criteria by evaluating various defect categories, which include

Contamination, Pit/Chip and Scratches.

Note: Zones are a series of concentric circles that identify areas of interest on the

connector end face. The inner-most zones are more sensitive to contamination than the

outer zones.

FiberChekPRO HTML Summary Report

FiberChekPRO User Interface

A

CORE Zone

B

CLADDING Zone

C

FERRULE/CONTACT Zone

SINGLE-MODE FIBER