Analysis software, Zoom in on clarity, Save time and money – Atec EXFO-FIP-400 User Manual

Page 2: Complete test reports for future referencing, Fiber probe viewer video inspection probe, Fip-400 fiber inspection probe

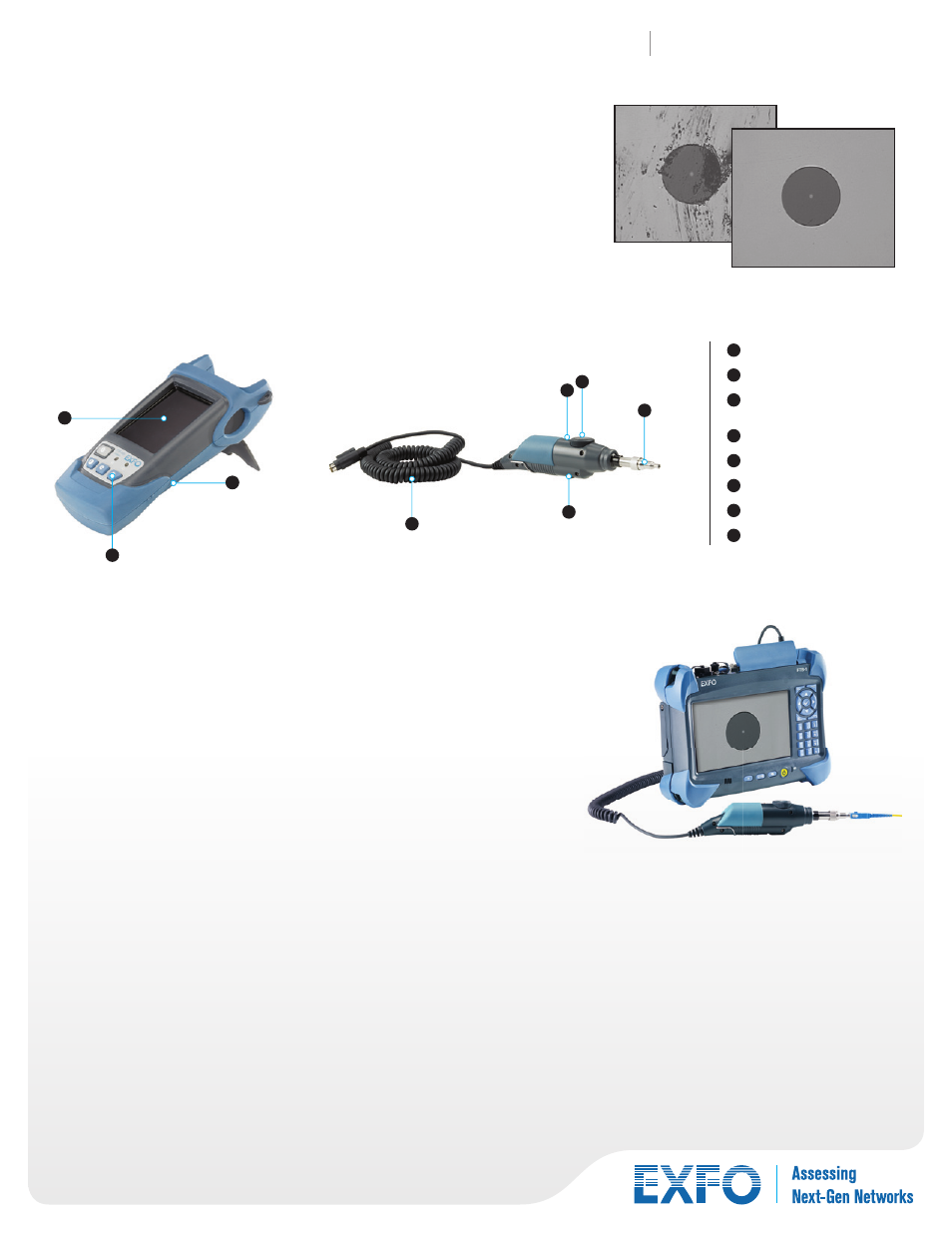

FIP-400 Fiber Inspection Probe

C

ONNECTOR

M

AX

ANALYSIS SOFTWARE

Automatic pass/fail analysis with multiple-platform flexibility

›

Available on the portable FTB-1, FTB-200 and FTB-500 platforms

Save time and money

›

Lightning-fast results in seconds through simple one-touch operation

Complete test reports for future referencing

›

Stores images and results for record-keeping

Delivering fast pass/fail assessment of connector endfaces, EXFO’s

ConnectorMax Analysis Software is designed to save both time and money in

the field. The industry’s first platform-based, automated inspection application,

ConnectorMax eliminates guesswork, instead providing clear-cut connector

endface analysis.

ConnectorMax enables field technicians to analyze defects and scratches and

measure their impact on connector performance. Results are then compared

against pre-programmed IEC/IPC standards or user-defined criteria, leading

to accurate pass/fail verdicts established right on-site.

ConnectorMax therefore helps avoid two time- and money-consuming situations:

undetected connector defects that force technicians to later return to the site,

and unnecessary replacement of connectors whose slight defects are not

enough to get a “fail” verdict.

Automatic pass/fail analysis in any FTB platform

ZOOM IN ON CLARITY

It’s a known fact: optical network problems are often caused by dirty and/or

damaged connectors. Using a fiber inspection probe to ensure that connectors/

adapters are clean and exempt of any defect is where accurate testing starts.

Thanks to EXFO’s FIP-400 Fiber Inspection Probe, checking connectors and

other fiber terminations for polish quality and cleanliness has never been easier.

Benefit from the best optical resolution in the industry and see scratches and dirt

particles as small as 1 µm. Also, use a USB converter to send image captures to a

portable platform or a PC.

Dirty connector

Clean connector

Fiber Probe Viewer

Video Inspection Probe

1

72

3

4

8

5

6

7

1

3.5” TFT LCD screen

2

Rechargeable Li-ion battery

3

Adjustable brightness

and contrast

4

Probe connector (EXFO type)

5

Image capture button

6

Focusing device

7

Interchangeable tip

8

Magnification knob (dual model)