Atec CorDEX-UT5000 User Manual

Ut5000, Intrinsically safe thickness gauge

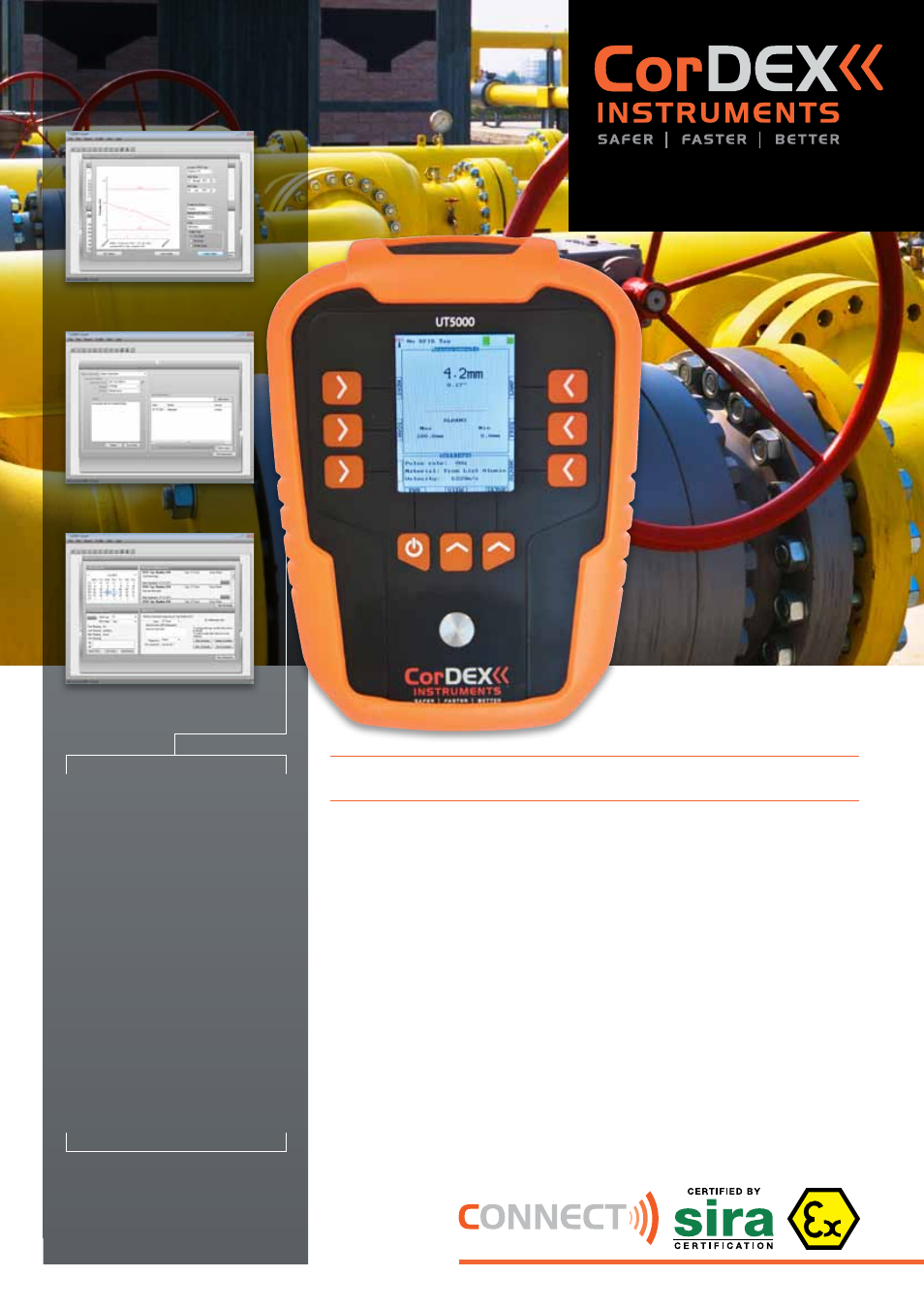

INTRINSICALLY SAFE THICKNESS GAUGE

CorDEX Instruments UT5000

Intrinsically Safe thickness gauge with CorDEX

CONNECT™ measures metal thickness for Non-Destructive Testing (NDT) and Predictive

Maintenance (Pdm) on pipelines and fixed equipment within hazardous locations.

UT5000 is a next generation thickness gauge packed with proven technologies: CorDEX

CONNECT™ uses RFID + Software to tag measurements with their location then

organises the data, giving the engineer a view of the pipeline at any specific location;

the unique corrosion mode feature helps identify spots of thinning; whilst MultiECHO™

technology helps to improve accuracy on uneven surfaces. Also incorporating Echo-

Echo functionality, the UT5000 is able to take thickness readings through protective

paints without having to remove the coating.

Designed for rugged environments, the shock resistant skin protects a 3.1 inch (8cm)

colour screen and has easy-to-feel raised buttons. The intrinsically safe dual-element,

4MHz transducer is adjustable up to 8Hz with accuracy of +/- 0.05mm (0.01inch).

UT5000

» ATEX and IECEx

Certified for Zone

1 IIC T4 hazardous

vapour areas

» ATEX and IECEx

Certified for ibD IIIB

T200˚C Db hazardous

dust areas

» Features CorDEX

CONNECT™

» Full Colour,

Backlit Screen

CorDEX CONNECT

TM

Software

Enhanced Reporting

Realtime Tracking

Maintenance Scheduling

Re

f.ID 2301, R

ev.

C