Hi lo c, Hi lo v – Atec Chroma-19020 Series User Manual

Page 2

V

s

V

µA

Hi

Lo

C

x

V

µA

Hi

Lo

C

c

V

s

C

x

V

µA

Hi

Lo

V

s

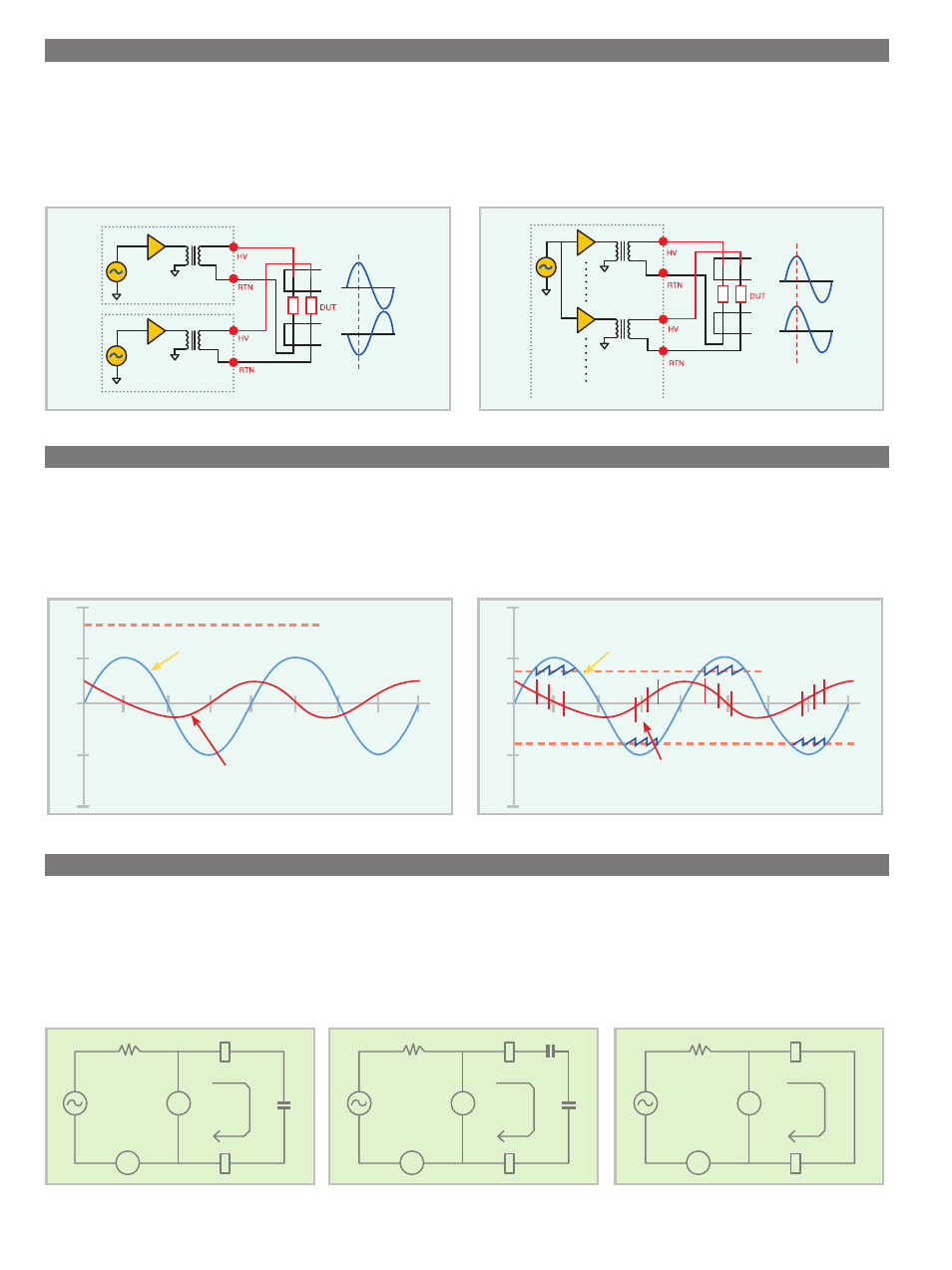

SYNCHRONOUS HI-POT TEST

The issue frequently encountered when testing multiple DUTs for Hipot is unable to synchronize the voltage output. When planning for production line or

automation, minimized facility and optimized space are often utilized in the plant; therefore, the distance between two DUTs is usually very short. Taking the

output voltage 5kVac for example, when the output of Hipot tester is not synchronized, the two DUTs may create a discharge of high voltage difference (up

to14kV peak-peak) and cause the fixture to be damaged and erroneous judgment. Chroma 19020 synchronizes the output signal so there is no high voltage

difference on the adjacent two ends that not only can extend the life of production equipment but also reduce the occurrence of misjudgment.

FLASHOVER DETECTION

Same as other Chroma EST Series, 19020 has Flashover detection function. Flashover is the electrical discharge generated by high electric field inside or on the

surface of insulation material that makes the DUT to lose its insulation characteristic and form a transient or discontinuous discharge. It can cause a carbonized

conductive path or damage the product under test. Flashover cannot be detected by monitoring leakage current only. The change rates of test voltage or

leakage current are monitored to detect flashover as its detection is one of the most indispensable test items for electrical safety test.

OPEN / SHORT CHECK (OSC)

OSC function can check if there is any Open (bad connection) or Short (DUT short circuited) occurred during test. If a DUT is open circuit during test, the unit

might be misjudged as a good one. If a DUT has short circuit, OSC function can filter it out to diminish the damage to fixture and save the test cost.

In general, products under Hi-pot test have capacitance (C

X

). C

X

could be tens of pF to several μF in normal condition. When the circuit connection is

interrupted, a small capacitance (Cc in Figure 6) will be formed on the broken interface that is usually lower than 10pF. It makes the entire capacitance of the

product lower than normal value. The capacitance of a product may be higher than normal when the product is short-circuited or near short circuit. Thus the

high/low limit of capacitance variation can be used to identify the short circuit problem.

10

-10

Test Voltage Waveform

Gap Discharge Voltage

180

360

Leakage Current (normal capacitive)

0

10

-10

Test Voltage Waveform

Gap Discharge Voltage

180

360

Leakage Current (abnornmal with flashover)

0

Figure 1 : Unsynchronized Output

~0kV

10 Channel Output

~14kV p-p

Figure 3 : Normal Leakage Current Waveform

Figure 2 : Synchronized Output

Figure 4 : Leakage Current Waveform when Flashover occurred

Figure 5 : Normal Connection

Figure 6 : Connection Open

Figure 7 : Connection Short