K. prepare factory bumper for assembly – American Expedition Vehicles JK Rear Bumper/Tire Carrier User Manual

Page 15

13

J. TIGHTENING SEQUENCE AND ADJUSTMENT OF THE REAR BUMPER

1. Once all the bolts have been started, check to see that the bumper is level from side to side, and

rotate the tire carrier as shown in STEP E. Replace the SHIM pack and adjust if necessary, tighten

the 1/2-13 bolts.

2. Next tighten the L BRACKET bolts and last the 5/16 bolts into the HANDLE NUT.

K. PREPARE FACTORY BUMPER FOR ASSEMBLY

1. NOTE: This step is for those who are installing the AEV Tire Carrier with the factory bumper. Pro-

ceed to step L if you are installing the AEV JK Rear Bumper and Tire Carrier.

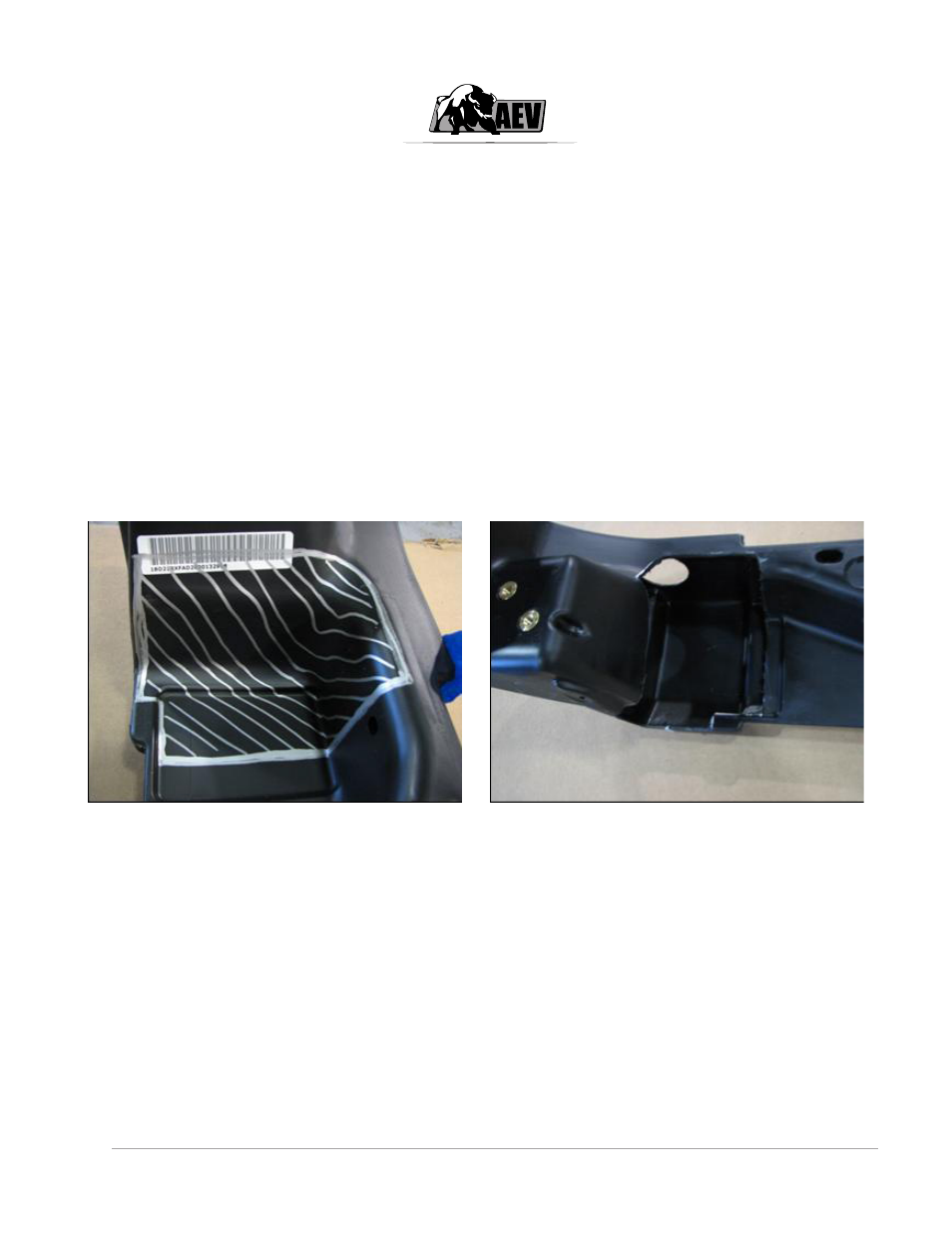

2. Working on the underside of the bumper, using a grey marker, markup the bumper as shown below.

This is where you will cut to allow clearance for the Spindle Housing. Be careful not to cut away too

much or cut through the outer surface of the bumper. You can trim later as necessary if you need

more clearance. The trimming operation is best done using a small reciprocating air saw or cut off

wheel.

3. Cut out the Spindle Tube template provided. Turn the bumper right side up and locate the template

on the top surface of the bumper. You will see a distinct parting line on the forward tangent of the

bumper as indicated in the photo. Position the template along the parting line and the rearward

upper tangent. Secure to the bumper with masking tape. Mark the center of the hole with a center

punch and drill using a 2 ¾” hole saw.