Cla-Val 2100G User Manual

Deluge valve, Typical application, Models

100G

2100G

• U.L. Listed / U.L.C. Listed/ABS Approved

• Globe or Angle Pattern

• Proven Reliable Design

The Cla-Val Model 100G/2100G Deluge Valve is designed for use in controlling water

flow to Deluge, Pre-Action, or Foam-Water type fire protection sprinkler systems. This

valve is U.L. Listed in "Special Systems Water Control Valves Class I (VLFT)".

The Model 100G/2100G is a hydraulically-operated, diaphragm-actuated, globe or angle

pattern Deluge Valve. It consists of three major components: the body, the cover, and

the diaphragm assembly. The only moving part is the diaphragm assembly. Packless

construction and simplicity of design assures long service life and dependable low main-

tenance for this valve. All ferrous parts are fusion epoxy coated internally and externally

for added corrosion resistance, along with a delrin sleeve stem and teflon coated remov-

able seat.

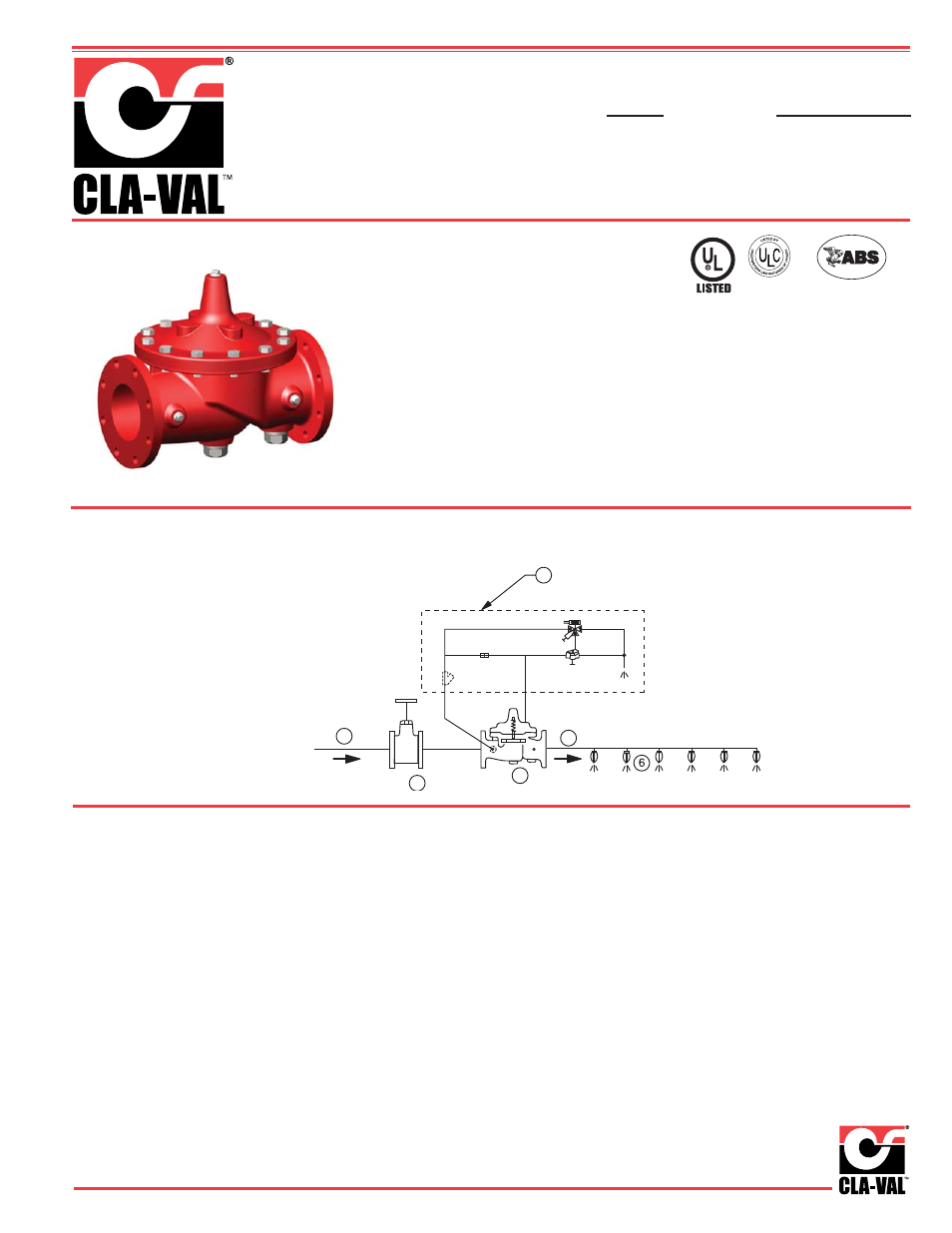

Typical Application

Deluge Valve

The Model 100G/2100G is installed to control the water flow to the sprinklers

in Deluge, Pre-Action, or Foam-Water type systems.

A simplified system is used to illustrate typical operation.

The Model 100G/2100G Deluge Valve (3) is main-

tained in the closed position by means of system

water pressure controlled by a pilot control (4).

When the pilot control valve receives a signal from

the fire detection system, it allows the deluge valve

to open. Firefighting water (1) then enters

system piping (5) and discharges

from sprinklers (6).

4

1

2

3

5

(1) From System Water Supply

(2) System Shut-off Valve (Visual Stem)

(3) Cla-Val Model 100G or 2100G

(4) Pilot Control System

(5) Sprinkler System Piping

(6) Sprinklers

MODELS

Globe: 3" – 10" • Angle:

3" – 10"

Ductile Iron 150 ANSI B16.42 flanged

Cast Steel 150 ANSI B16.5 flanged

150 class, 250 psi maximum (Ductile Iron)

150 class, 285 psi maximum (All other materials)

300 class, 300 psi maximum (All materials)

Water, to 180°F MAX.

Main Valve Body & Cover:

• Ductile Iron ASTM A-536* UL, ULC

• Cast Steel ASTM A216-WCB* UL, ULC

• Nickel Aluminum Bronze ASTM B148 UL, ULC

•

Naval Bronze ASTM B61 UL, ULC

• 316 Stainless Steel - ASTM A743 Grades

CF3M and CFM8

• Super Austenitic Stainless Steel - ASTM A351

Grade CK3MCuN (SMO 254)

• Super Duplex Stainless Steel - ASTM A890

Grade 5A (CE3MN)

Main Valve Internal Trim:

Bronze ASTM B61 • Monel QQ-N-281 Class B

Diaphragm and Disc:

Buna-N

®

synthetic rubber

*Internally & Externally Epoxy Coated

Sizes

End Details

Pressure Rating

Temperature Range

Materials

1. Model No. 100GS or 2100GS

2. Size

3. Body and Cover Material

4. Globe or Angle Pattern

5. Pressure Class

6. Internal Trim Material

When Ordering, Please Specify

Friction Loss

For use in hydraulically calculated

systems, friction loss equivalent to:

Specifications

100GS (Globe):

3" Size=42 Ft. of 3" Pipe

4" Size=92 Ft. of 4" Pipe

6" Size=116 Ft. of 6" Pipe

8" Size=123 Ft. of 8" Pipe

10" Size=201 Ft. of 10" Pipe

2100GS (Angle):

3" Size=33 Ft. of 3" Pipe

4" Size=44 Ft. of 4" Pipe

6" Size=79 Ft. of 6" Pipe

8" Size=105 Ft. of 8" Pipe

10" Size=153 Ft. of 10" Pipe

Specifications Seawater Service Option

Sizes

Globe: 3" - 10" flanged

Angle: 3" - 10" flanged

Consult factory for materials and flange ratings.

D E S I G N

A S S E S S E D

Type Approved